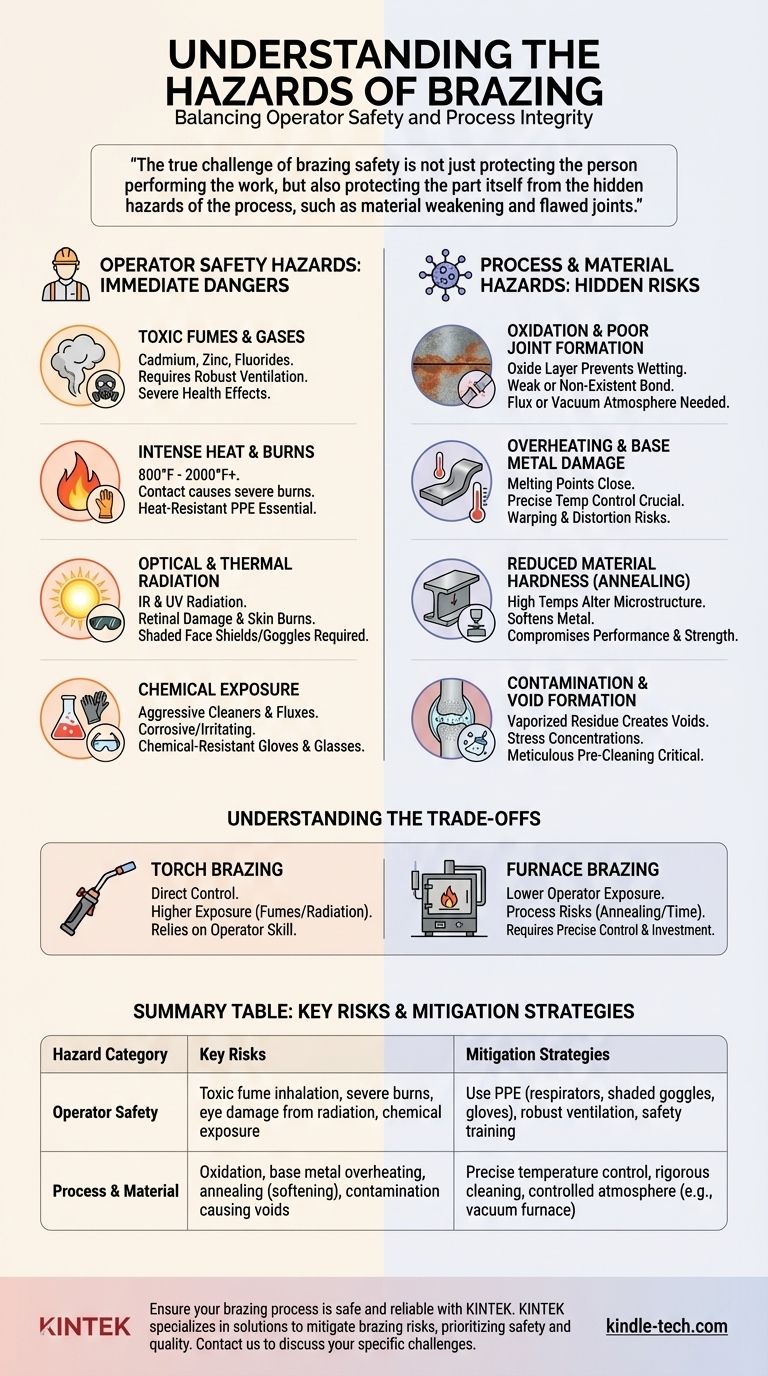

At its core, brazing introduces two distinct categories of hazards: immediate physical dangers to the operator and complex process risks that can compromise the integrity of the finished component. Operator hazards include exposure to toxic fumes, intense heat, and chemicals, while process hazards involve material degradation, oxidation, and improper joint formation that can lead to part failure.

The true challenge of brazing safety is not just protecting the person performing the work, but also protecting the part itself from the hidden hazards of the process, such as material weakening and flawed joints.

Operator Safety Hazards: The Immediate Dangers

These are the most direct and well-understood risks associated with any high-temperature joining process. They require strict adherence to personal protective equipment (PPE) and environmental controls.

Toxic Fumes and Gases

Many brazing filler metals contain elements like cadmium or zinc which produce highly toxic fumes when heated. Cadmium, in particular, is a known carcinogen with severe long-term health effects.

Additionally, fluxes used in the process can release fluoride or other hazardous gases, requiring robust ventilation to prevent inhalation.

Intense Heat and Burns

Brazing temperatures often range from 800°F to over 2000°F (450°C to 1150°C). Direct contact with the torch flame, heated parts, or furnace elements will cause severe burns.

Proper handling procedures, heat-resistant gloves, and protective clothing are non-negotiable safety measures.

Optical and Thermal Radiation

The bright glow of the heated metal and filler alloy emits intense infrared (IR) and ultraviolet (UV) radiation. This can cause retinal damage and skin burns with prolonged exposure.

Shaded face shields or specialized brazing goggles (typically shade #3 or #4) are essential to protect the operator's eyes.

Chemical Exposure

Brazing often requires aggressive cleaning agents or acidic/alkaline fluxes to prepare the surface. These chemicals can be corrosive or irritating upon skin contact or inhalation.

Careful handling, chemical-resistant gloves, and safety glasses are necessary when working with these pre-cleaning and flux materials.

Process & Material Hazards: The Hidden Risks

These hazards do not pose an immediate threat to the operator but are critical risks to the quality, reliability, and structural integrity of the final brazed assembly.

Oxidation and Poor Joint Formation

As noted with materials like aluminum, a stubborn oxide layer can form instantly on the base metal surface. This layer prevents the filler metal from "wetting" the surface and flowing into the joint.

If this oxide layer is not removed by flux or a vacuum atmosphere, the result is a weak or non-existent bond, which is a critical failure hazard.

Overheating and Base Metal Damage

The melting points of some filler metals can be very close to the melting point of the base metals. This requires extremely precise temperature control.

Accidentally overheating the assembly can melt, distort, or warp the parent parts, rendering them useless.

Reduced Material Hardness (Annealing)

The high temperatures involved in brazing, especially in a prolonged furnace cycle, can alter the microstructure of the base material. This process, known as annealing, softens the metal.

For heat-treated or work-hardened components, this reduction in hardness and strength can compromise the part's designed performance and lead to mechanical failure in service.

Contamination and Void Formation

Any oil, dirt, or residual cleaning agent left in the joint area will vaporize during heating, creating gas pockets or voids. These voids create stress concentrations and dramatically reduce the strength of the joint.

Meticulous pre-cleaning is not just a best practice; it is a critical step to mitigate the hazard of a structurally deficient bond.

Understanding the Trade-offs

Choosing a brazing method involves balancing operator safety, process control, and cost. Each choice comes with a different risk profile.

Torch Brazing vs. Furnace Brazing

Torch brazing gives an operator direct control but significantly increases exposure to fumes and radiation. It also relies on operator skill to prevent localized overheating.

Furnace brazing, including vacuum brazing, removes the operator from direct exposure but introduces process risks. It requires longer cycle times, consumes more energy, and carries a greater risk of part softening (annealing) if not managed perfectly.

The Cost of Control

Achieving the precise control needed to mitigate process hazards has costs. Vacuum furnaces are expensive, and thorough multi-stage cleaning processes add time and expense for chemical handling and disposal.

Failing to invest in these controls doesn't save money; it simply transfers the risk to the finished product in the form of potential failure.

Making the Right Choice for Your Goal

Your approach to managing brazing hazards depends entirely on what you are trying to protect.

- If your primary focus is operator safety: Prioritize local exhaust ventilation, mandated PPE (respirators, shaded shields, gloves), and thorough chemical handling training.

- If your primary focus is product integrity: Implement rigorous pre-cleaning protocols, use precise temperature controllers or automated furnace cycles, and perform post-braze testing to verify material hardness and joint quality.

- If your primary focus is process efficiency: Analyze the trade-offs between manual (torch) and automated (furnace) methods to find the balance of speed, cost, and risk that meets your quality standards.

Ultimately, a successful brazing operation is one where both the operator and the component are fully protected from the hazards of the process.

Summary Table:

| Hazard Category | Key Risks | Mitigation Strategies |

|---|---|---|

| Operator Safety | Toxic fume inhalation, severe burns, eye damage from radiation, chemical exposure | Use PPE (respirators, shaded goggles, gloves), robust ventilation, safety training |

| Process & Material | Oxidation, base metal overheating, annealing (softening), contamination causing voids | Precise temperature control, rigorous cleaning, controlled atmosphere (e.g., vacuum furnace) |

Ensure your brazing process is safe and reliable with KINTEK.

Whether you're brazing in a lab or a production environment, managing hazards is critical for protecting your team and your components. KINTEK specializes in lab equipment and consumables, offering solutions like controlled atmosphere furnaces, temperature monitoring systems, and safety accessories to mitigate brazing risks.

Let us help you achieve strong, consistent joints while prioritizing safety. Contact us today to discuss your specific brazing challenges and explore our tailored solutions.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing