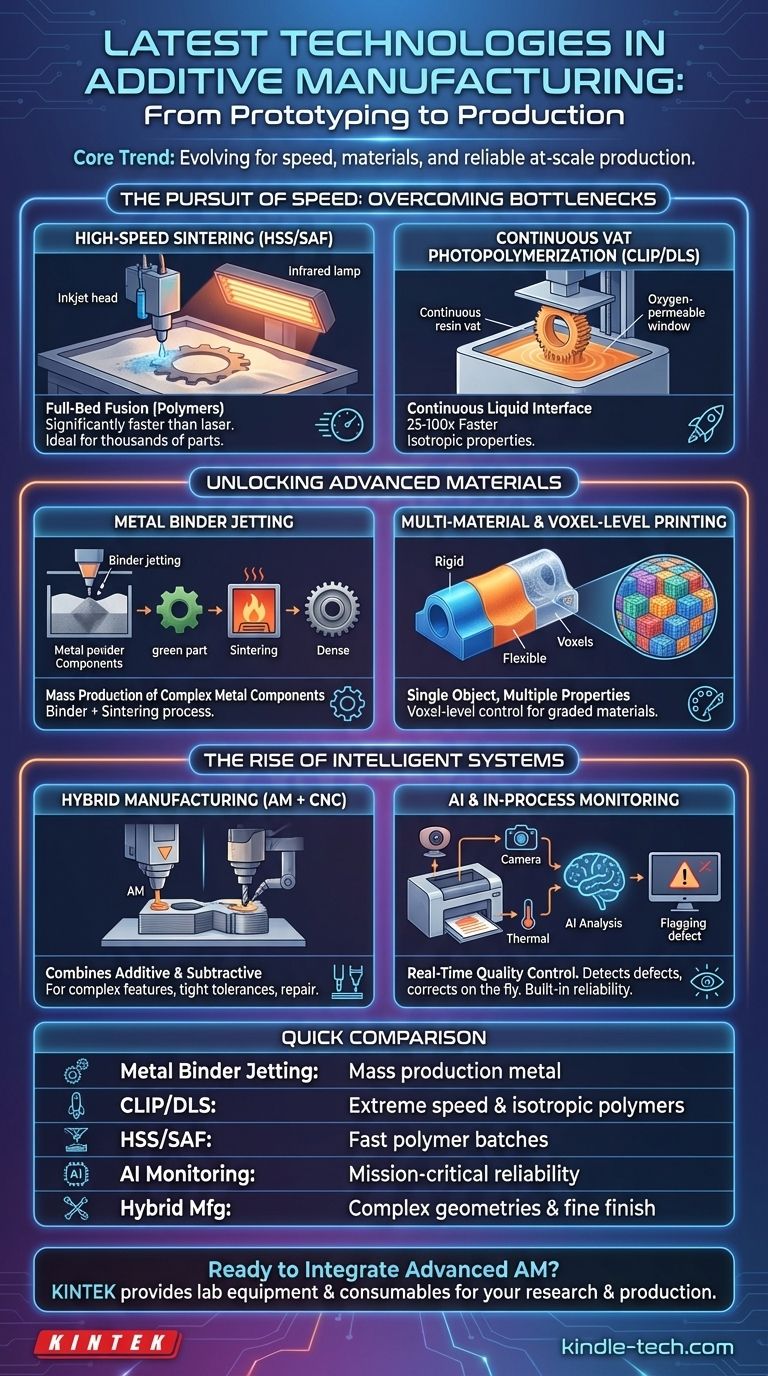

While no single technology is entirely "new," the latest advancements in additive manufacturing focus on making the process faster, more reliable, and capable of producing end-use parts from a vast range of high-performance materials. Key innovations include metal binder jetting for mass production, continuous liquid interface production (CLIP) for speed with polymers, and the integration of AI for real-time quality control.

The core trend in modern additive manufacturing is its evolution from a rapid prototyping tool into a viable, at-scale production method. The latest technologies are not just novelties; they are direct solutions to the historical bottlenecks of speed, material limitations, and quality assurance.

The Pursuit of Speed: Overcoming Production Bottlenecks

A primary obstacle to adopting additive manufacturing (AM) for production has always been its speed. Several new approaches are directly challenging traditional manufacturing methods like injection molding and CNC machining in terms of throughput.

High-Speed Sintering (HSS/SAF)

High-Speed Sintering (HSS) and the similar Selective Absorption Fusion (SAF) are powder-bed fusion technologies for polymers.

Instead of a slow-moving laser, these systems use an inkjet print head to deposit a radiation-absorbing fluid onto the powder bed in the shape of the part. An infrared lamp then passes over the entire bed, fusing only the areas where the fluid was deposited.

This full-bed fusion approach is significantly faster than point-by-point laser sintering, making it a powerful tool for producing thousands of parts.

Continuous Vat Photopolymerization (CLIP/DLS)

Traditional vat photopolymerization (SLA/DLP) prints layer-by-layer, with a mechanical "peel" step between each layer that slows the process dramatically.

Technologies like Carbon's Digital Light Synthesis (DLS), often known by its foundational technology CLIP, eliminate this peel step. They use an oxygen-permeable window that creates a continuous liquid interface, allowing the part to be pulled from the resin vat in a smooth, uninterrupted motion.

This results in a 25 to 100 times increase in printing speed and produces parts with isotropic properties, meaning they are equally strong in all directions.

Unlocking Advanced Materials: Beyond Basic Plastics

The true value of AM is realized when it can create functional parts from materials engineered for demanding applications. Recent advancements have unlocked metals, composites, and high-performance polymers for production use.

Metal Binder Jetting

Metal binder jetting is poised to revolutionize metal manufacturing. The process involves depositing a liquid binding agent onto a bed of metal powder, layer by layer, to form a "green" part.

This green part is then placed in a furnace for a process called sintering, where the binder is burned away and the metal particles fuse into a dense, solid object.

The key advantage is speed and cost. A binder jetting machine can produce parts far more quickly and in higher volumes than laser-based metal printers, opening the door to mass production of complex metal components.

Multi-Material & Voxel-Level Printing

One of the most exciting frontiers is the ability to print a single object with multiple materials or with properties that vary throughout its structure.

Systems using material jetting can deposit different photopolymers in the same build, creating parts that are both rigid and flexible, or opaque and transparent.

This is often referred to as voxel-level control, where each three-dimensional pixel (voxel) can be assigned a specific material property, enabling the creation of functionally graded materials that are impossible to produce with any other method.

The Rise of Intelligent Systems

To move into mission-critical production, AM systems must be reliable and repeatable. The integration of advanced software and hardware is making this a reality.

Hybrid Manufacturing (AM + CNC)

Hybrid manufacturing systems combine an additive process (like Directed Energy Deposition) and a subtractive process (like CNC milling) within a single machine.

This allows a machine to add material to build a feature and then immediately machine it to achieve tight tolerances and a fine surface finish. This is particularly useful for repairing high-value components or creating complex parts with internal features that would be impossible to machine conventionally.

AI and In-Process Monitoring

Modern industrial AM systems are equipped with a suite of sensors, including cameras and thermal detectors, that monitor each layer of the build process.

Artificial intelligence and machine learning algorithms analyze this data in real-time to detect potential defects, such as warping or insufficient fusion. The system can then automatically correct parameters on the fly or flag a build for inspection, ensuring quality control is built into the process, not just inspected afterward.

Understanding the Inherent Trade-offs

While these technologies are powerful, they are not universal solutions. Choosing the right one requires understanding their limitations.

Speed vs. Resolution

As a general rule, higher printing speeds often come at the expense of fine detail and surface finish. Processes optimized for mass production may not be suitable for applications requiring intricate features.

The Post-Processing Reality

"Printing" is rarely the final step. Metal binder jetting requires a lengthy and complex sintering process. Vat photopolymerization parts need washing and curing. These post-processing steps add significant time and cost and must be factored into any production plan.

Material Cost and Ecosystem Lock-in

Many of these advanced technologies are part of closed ecosystems, requiring the use of proprietary materials sold by the machine manufacturer. These materials can be significantly more expensive than commodity plastics or metal powders, impacting the final part cost.

Selecting the Right Technology for Your Goal

Your application dictates the most appropriate technology.

- If your primary focus is rapid, high-fidelity prototyping: Continuous vat photopolymerization (CLIP/DLS) offers exceptional speed and surface finish for polymer parts.

- If your primary focus is low-to-medium volume production of functional polymer parts: High-speed sintering (HSS/SAF) is a direct and powerful competitor to injection molding.

- If your primary focus is mass production of complex metal components: Metal binder jetting is the key emerging technology to investigate for lowering costs and increasing throughput.

- If your primary focus is creating mission-critical parts with guaranteed quality: Laser Powder Bed Fusion (LPBF) combined with AI-driven in-process monitoring remains the gold standard for performance and reliability.

By understanding these evolving capabilities, you can leverage additive manufacturing as a strategic tool for genuine production, not just experimentation.

Summary Table:

| Technology | Primary Benefit | Ideal For |

|---|---|---|

| Metal Binder Jetting | High-speed, low-cost metal parts | Mass production of complex metal components |

| CLIP / DLS | Extreme speed and isotropic properties | Rapid prototyping and production of polymer parts |

| High-Speed Sintering (HSS/SAF) | Fast, full-bed fusion for polymers | Low-to-medium volume production runs |

| AI & In-Process Monitoring | Real-time defect detection and quality control | Mission-critical parts requiring high reliability |

| Hybrid Manufacturing (AM + CNC) | Combines complex geometries with fine tolerances | Repairing parts or creating complex internal features |

Ready to Integrate Advanced Additive Manufacturing into Your Lab?

Navigating the latest AM technologies can be complex. KINTEK specializes in providing the right lab equipment and consumables to support your additive manufacturing research and production needs. Whether you're exploring new materials, scaling up production, or implementing quality control systems, our expertise can help you achieve your goals.

Contact us today to discuss how we can support your laboratory's journey into advanced manufacturing. Get in touch via our contact form and let's build the future, together.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Three-dimensional electromagnetic sieving instrument

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- How does a laboratory hydraulic press contribute to MIC testing? Ensure Precision in Stainless Steel Specimens

- What is a hot mounting press machine? Precision Control for Metallurgy & Electronics Assembly

- What is the process of mounting in metallurgy? A Guide to Perfect Specimen Preparation

- How should an RVC sheet be handled and set up during an experiment? Ensure Precision and Data Integrity

- What is the general procedure and what precautions should be taken during the polishing process? Achieve a Flawless Electrode Finish