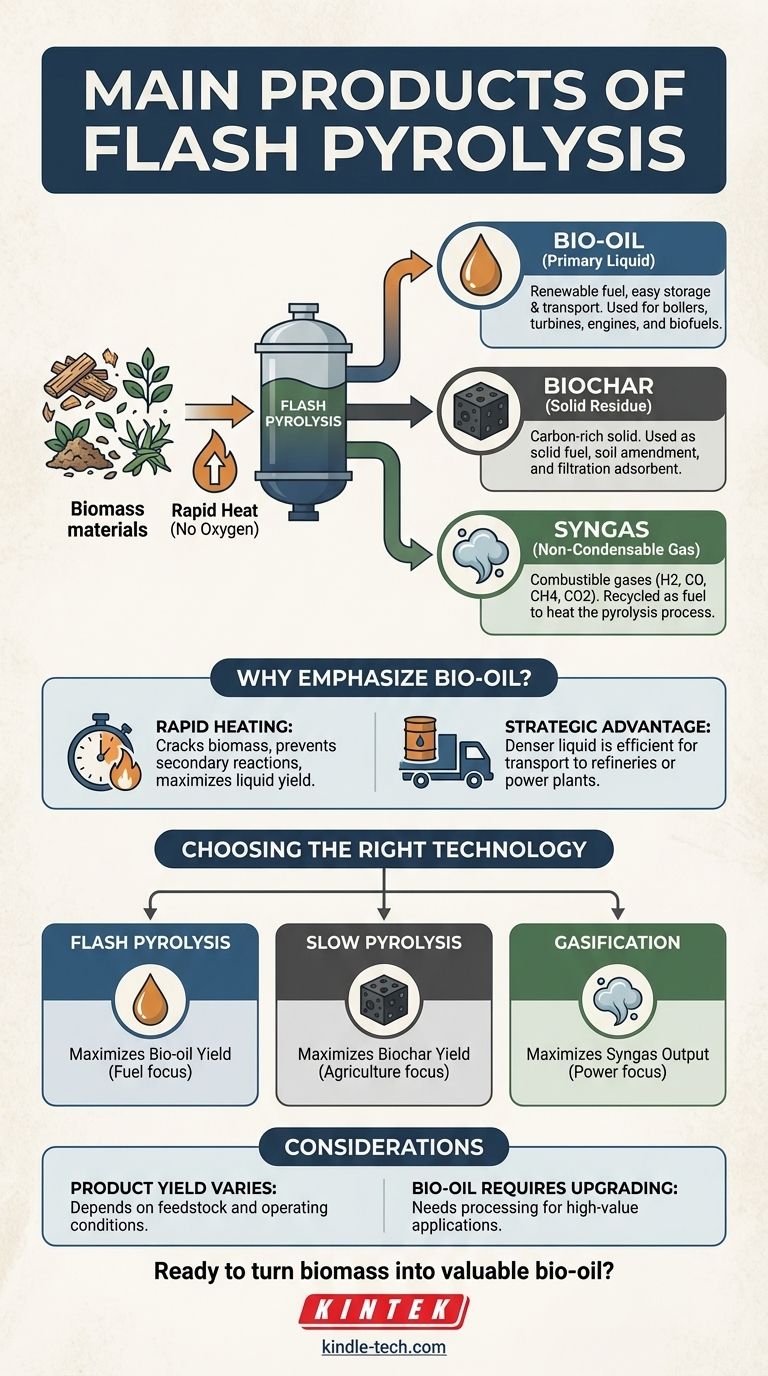

The primary products of flash pyrolysis are a liquid known as bio-oil, a solid called biochar, and a non-condensable syngas. The process is specifically engineered to heat organic material (like biomass) extremely quickly in the absence of oxygen, which maximizes the yield of the valuable liquid component.

While flash pyrolysis creates products in all three states of matter—solid, liquid, and gas—its defining feature is the optimization of the process to produce the highest possible yield of energy-dense, transportable bio-oil.

The Three Core Products Explained

Flash pyrolysis breaks down complex organic matter into simpler, more valuable components. Each of the three main products has distinct properties and applications.

The Primary Liquid: Bio-oil

Bio-oil (also called pyrolysis oil) is a dark, viscous liquid and is typically the main target product of flash pyrolysis. It's a complex mixture of oxygenated organic compounds.

This liquid is prized because, unlike raw biomass, it can be easily stored and transported. It serves as a renewable fuel source for boilers, turbines, and certain engines, and can also be refined into advanced biofuels or used as a source for specialty chemicals.

The Solid Residue: Biochar

Biochar (also known as biocoal or coke) is the stable, carbon-rich solid that remains after the volatile components have been driven off.

This material has several important uses. It can be burned as a solid fuel, used as an adsorbent for filtration, or, most notably, applied to soil as an agricultural amendment to improve fertility and sequester carbon.

The Non-Condensable Gas: Syngas

Syngas (or pyrolysis gas) is a mixture of combustible gases, including hydrogen, carbon monoxide, methane, and carbon dioxide.

This gas has a lower energy density than natural gas but is highly useful. In most pyrolysis plants, the syngas is captured and immediately recycled as fuel to provide the heat required for the pyrolysis process itself, making the system more energy-efficient and self-sustaining.

Why Flash Pyrolysis Emphasizes Bio-oil

Understanding why this process is designed to favor one output over the others is key to appreciating its value.

The Goal of Rapid Heating

The term "flash" refers to the extremely high heating rates used. This rapid thermal decomposition cracks the biomass molecules and drives them off as vapor before they can undergo secondary reactions that would form more biochar and gas.

These vapors are then rapidly cooled and condensed, which results in the high yield of liquid bio-oil. Slower pyrolysis processes, by contrast, would produce significantly more biochar.

The Strategic Advantage of a Liquid Fuel

The focus on producing a liquid is driven by logistics and economics. A liquid fuel is far denser and easier to store and transport than raw biomass or pyrolysis gas.

This allows biomass resources to be converted into a valuable energy commodity at a local facility, which can then be shipped efficiently to a central refinery or power plant for use.

Understanding the Trade-offs

While powerful, flash pyrolysis is not a perfect solution and comes with important considerations.

Product Yield Varies

The exact percentage of bio-oil, biochar, and syngas produced is not fixed. It depends heavily on the specific feedstock used (e.g., wood chips, corn stover, or municipal waste) and the precise operating conditions of the reactor.

Bio-oil Requires Upgrading

Raw bio-oil is not a direct "drop-in" replacement for petroleum fuels. It is typically acidic, contains a significant amount of water, and can be chemically unstable over time.

For most high-value applications, such as use in internal combustion engines or as a feedstock for refineries, the bio-oil must undergo further processing and upgrading, which adds to the overall cost and complexity.

Applying This to Your Goal

The right thermal conversion technology depends entirely on your desired end product.

- If your primary focus is a transportable liquid fuel: Flash pyrolysis is the superior choice, as it is specifically designed to maximize the bio-oil yield.

- If your primary focus is a stable, carbon-rich solid for agriculture: A slower pyrolysis process is more effective because it maximizes the production of biochar.

- If your primary focus is generating combustible gas for power: Gasification, a related process that uses a controlled amount of oxygen, is designed to maximize the output of syngas.

By understanding the distinct outputs of flash pyrolysis, you can better align the technology with your specific energy or material goals.

Summary Table:

| Product | State | Primary Use |

|---|---|---|

| Bio-oil | Liquid | Renewable fuel for boilers, turbines; feedstock for chemicals |

| Biochar | Solid | Solid fuel, soil amendment, filtration adsorbent |

| Syngas | Gas | Recycled to fuel the pyrolysis process |

Ready to turn biomass into valuable bio-oil?

KINTEK specializes in advanced lab equipment for pyrolysis research and process development. Whether you're optimizing bio-oil yield, characterizing biochar, or scaling up your process, our reactors and analytical tools provide the precision and reliability you need.

Contact our experts today to discuss how our solutions can help you achieve your renewable energy and material goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy