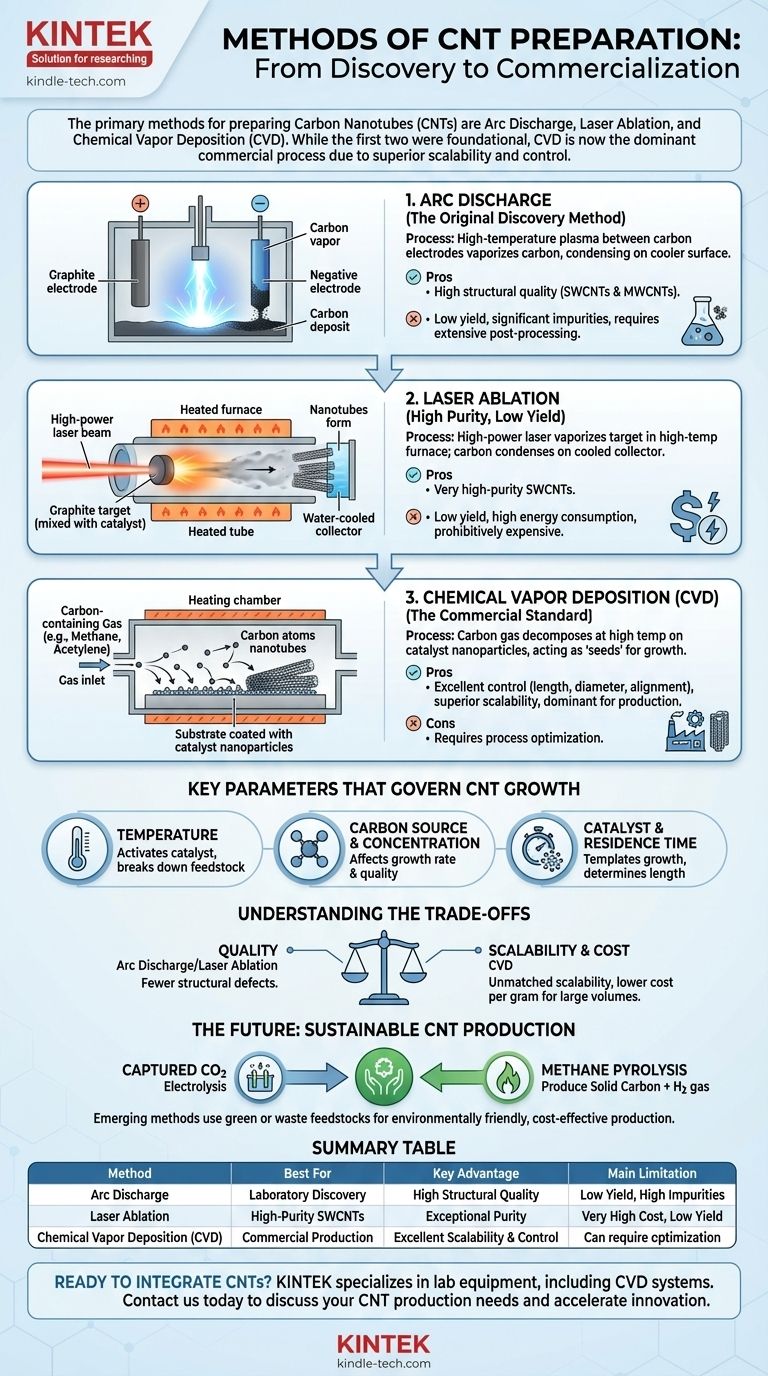

The primary methods for preparing Carbon Nanotubes (CNTs) are arc discharge, laser ablation, and Chemical Vapor Deposition (CVD). While the first two methods were foundational in the early research of CNTs, CVD has become the dominant process for commercial-scale production due to its superior scalability and control.

The core challenge in CNT synthesis is balancing production volume, material purity, and cost. While older methods produce high-quality material, Chemical Vapor Deposition (CVD) offers the most practical pathway for the large-scale manufacturing required for most modern applications.

The Three Foundational Synthesis Methods

Understanding the three main production techniques reveals the evolution from laboratory discovery to industrial production. Each method operates on a different principle to transform a carbon source into a nanostructure.

Arc Discharge: The Original Discovery Method

This method creates a high-temperature plasma arc between two carbon electrodes. The intense heat vaporizes the carbon from the positive electrode, which then condenses on the cooler negative electrode, forming CNTs.

It is effective for producing both single-walled and multi-walled CNTs of high structural quality. However, the resulting material is often mixed with significant impurities, such as amorphous carbon and catalyst particles, requiring extensive post-processing.

Laser Ablation: High Purity, Low Yield

In this technique, a high-power laser is aimed at a graphite target, often mixed with a metal catalyst, in a high-temperature furnace. The laser vaporizes the target, creating a plume of carbon atoms that condense into CNTs on a cooled collector.

Laser ablation is renowned for producing very high-purity single-walled CNTs (SWCNTs). Its primary drawbacks are low yield and high energy consumption, making it prohibitively expensive for most large-scale applications.

Chemical Vapor Deposition (CVD): The Commercial Standard

CVD is the most widely used method for commercial CNT production. The process involves introducing a carbon-containing gas (like methane or acetylene) into a high-temperature chamber containing a substrate coated with catalyst nanoparticles.

At high temperatures, the gas decomposes, and the carbon atoms assemble on the catalyst particles, which act as "seeds" for nanotube growth. CVD offers excellent control over CNT length, diameter, and alignment, and it is far more scalable than the other methods.

Key Parameters That Govern CNT Growth

The success of any synthesis method depends on carefully controlling several operating parameters. These variables directly influence the quality, structure, and yield of the final product.

The Role of Temperature

Temperature is arguably the most critical parameter. It provides the necessary energy to break down the carbon source (feedstock) and activates the metal catalyst particles that template the growth of the nanotubes.

Carbon Source and Concentration

The choice of carbon feedstock and its concentration in the reaction chamber affects the growth rate and quality. Different hydrocarbons decompose at different rates, influencing the final structure of the CNTs.

Catalyst and Residence Time

The catalyst (typically an iron, nickel, or cobalt nanoparticle) is the template upon which the nanotube forms. The residence time—how long the carbon source is exposed to the catalyst at temperature—directly impacts the final length of the nanotubes.

Understanding the Trade-offs

Choosing a synthesis method involves a clear understanding of the compromises between quality, quantity, and cost.

Quality vs. Scalability

Arc discharge and laser ablation can produce CNTs with fewer structural defects. However, CVD is unmatched in its ability to scale for industrial production, making it the only viable option for applications requiring large quantities of material, such as composites and electronics.

Cost and Complexity

The equipment and energy requirements for laser ablation make it the most expensive method. While arc discharge is simpler, its low yield and need for purification also lead to high effective costs. CVD can be optimized for continuous, large-scale production, significantly lowering the cost per gram.

The Future: Sustainable CNT Production

Emerging research is focused on making CNT synthesis more environmentally friendly and cost-effective by using alternative carbon sources.

Green and Waste Feedstocks

Innovations include using captured carbon dioxide (CO2) as a feedstock, which is converted to carbon through electrolysis in molten salts. Another promising route is methane pyrolysis, which splits natural gas into solid carbon (CNTs) and valuable hydrogen gas, offering a co-production benefit.

Making the Right Choice for Your Goal

Selecting the appropriate preparation method depends entirely on your end goal, balancing the need for purity, volume, and budget.

- If your primary focus is fundamental research or creating high-purity SWCNTs: Laser ablation remains a valuable, albeit expensive, laboratory technique.

- If your primary focus is commercial production for composites, electronics, or coatings: Chemical Vapor Deposition (CVD) is the definitive industry standard due to its scalability and control.

- If your primary focus is sustainability or novel processes: Exploring emerging methods using CO2 or methane pyrolysis represents the future of greener nanomaterial production.

Ultimately, understanding the principles behind each synthesis method empowers you to select the right tool for creating materials with specific, desired properties.

Summary Table:

| Method | Best For | Key Advantage | Main Limitation |

|---|---|---|---|

| Arc Discharge | Laboratory Discovery | High Structural Quality | Low Yield, High Impurities |

| Laser Ablation | High-Purity SWCNTs | Exceptional Purity | Very High Cost, Low Yield |

| Chemical Vapor Deposition (CVD) | Commercial Production | Excellent Scalability & Control | Can require optimization |

Ready to integrate Carbon Nanotubes into your research or product development? The right synthesis method is critical to achieving your goals for material purity, volume, and budget. KINTEK specializes in lab equipment and consumables for advanced material synthesis, including CVD systems. Our experts can help you select the ideal setup for your laboratory's specific needs. Contact us today to discuss how we can support your CNT production and accelerate your innovation.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the advantages of vapor deposition? Achieve Unmatched Thin-Film Precision & Performance

- What is the LPCVD method? Achieve Superior Thin-Film Uniformity for Complex Microstructures

- What is a deposition system? The Engine Behind Modern Electronics and Advanced Materials

- What is the difference between chemical vapor deposition and atomic layer deposition? Master Atomic-Level Control

- What is vapour deposition techniques? A Guide to PVD and CVD Coating Methods

- What is Chemical Vapor Deposition (CVD) in Graphene? Scale High-Quality Monolayer Production

- What is material deposition in manufacturing? Unlock Design Freedom with Additive Processes

- What are the sequential steps involved in the Chemical Vapor Deposition (CVD) process? Master the 6-Phase Lifecycle