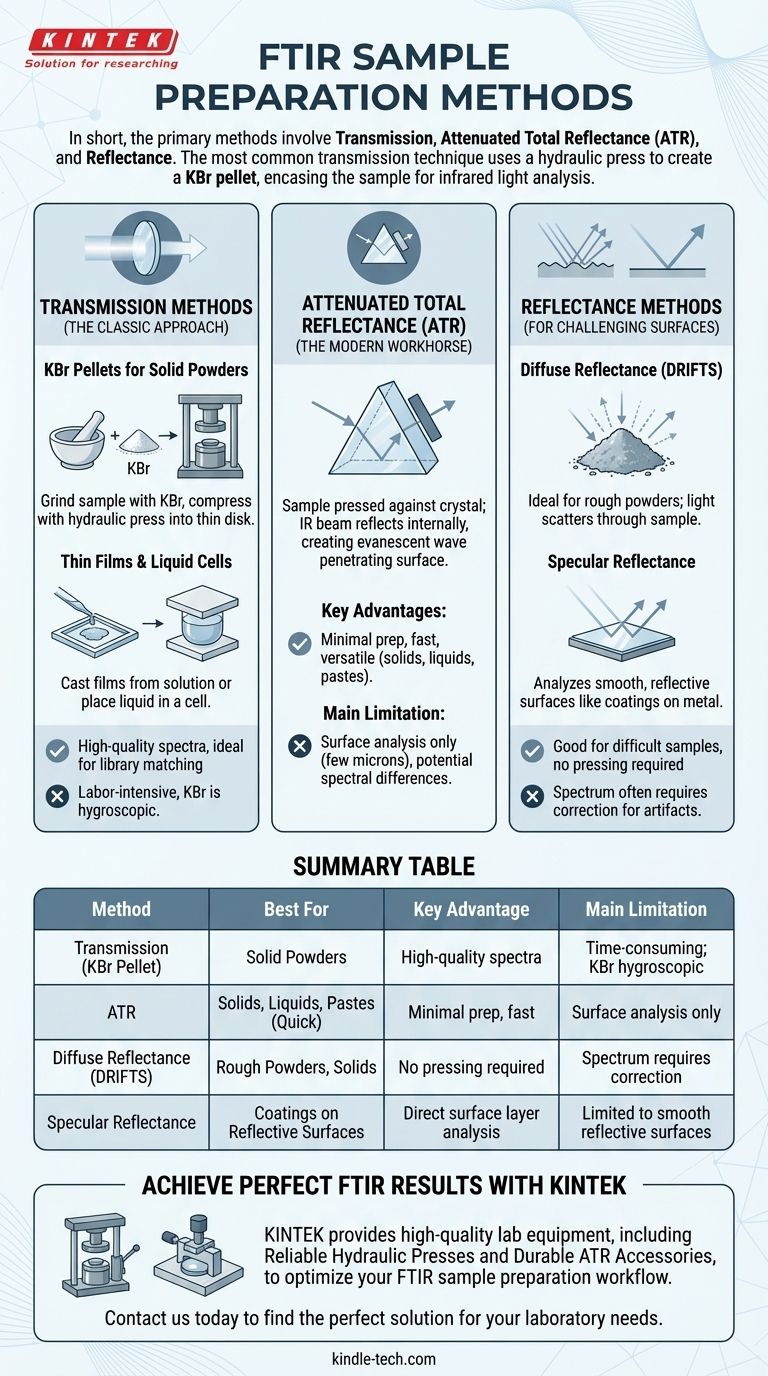

In short, the primary methods for FTIR sample preparation involve transmission, Attenuated Total Reflectance (ATR), and various forms of reflectance. The most common transmission technique uses a hydraulic press to create a potassium bromide (KBr) pellet, which encases the sample and allows infrared light to pass through for analysis.

The most critical factor in choosing a sample preparation method is the physical state of your sample. The goal is to select the technique that best matches your sample—whether it's a solid powder, a liquid, a polymer film, or a coating—to obtain a clean, useful spectrum with minimal effort.

Transmission Methods: The Classic Approach

Transmission is the original FTIR method, where the infrared beam passes directly through the sample. This requires the sample to be sufficiently thin and transparent to infrared light to allow for detection.

KBr Pellets for Solid Powders

This is a traditional and powerful technique for analyzing solid samples.

The process involves finely grinding a small amount of the sample with potassium bromide (KBr) powder, which is transparent to infrared radiation.

This mixture is then placed into a pellet die and compressed with a hydraulic press, forming a thin, semi-transparent solid disk or pellet for analysis.

Thin Films for Polymers

Some samples, particularly polymers, can be dissolved in a solvent and cast onto an IR-transparent window.

As the solvent evaporates, it leaves a thin film of the material. This film can then be analyzed directly via transmission. High-temperature film makers can also be used to press materials into a thin film.

Liquid Cells

For liquid samples, a small amount can be placed between two salt plates (like NaCl or KBr).

These plates are separated by a spacer of a known thickness, creating a cell that holds the liquid in the path of the IR beam.

Attenuated Total Reflectance (ATR): The Modern Workhorse

ATR has become one of the most popular sampling techniques due to its simplicity and speed. It is a surface analysis technique that requires little to no sample preparation.

The Principle of ATR

In ATR, the IR beam is directed into a special crystal (often diamond, zinc selenide, or germanium) with a high refractive index.

The sample is pressed firmly against this crystal. The IR beam reflects internally off the crystal surface, creating an "evanescent wave" that penetrates a few microns into the sample.

The sample absorbs energy from this wave at its characteristic frequencies, and the attenuated beam is then directed to the detector.

Key Advantages of ATR

ATR is extremely fast and versatile, working well for solids, powders, pastes, and liquids.

It eliminates the need for grinding, pressing pellets, or using solvents, making it the go-to method for rapid, routine analysis.

Reflectance Methods: For Challenging Surfaces

Reflectance techniques are designed for samples that are difficult to analyze by transmission or ATR, such as opaque materials or coatings on reflective surfaces.

Diffuse Reflectance (DRIFTS)

Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) is ideal for powdered or rough-surfaced solid samples.

The IR beam is directed onto the sample, where it scatters through the powder. The scattered, or diffusely reflected, light is then collected by mirrors and sent to the detector.

Specular Reflectance

This technique is designed for analyzing smooth, reflective surfaces, like a polymer coating on a metal mirror.

The IR beam reflects off the sample's surface at an equal but opposite angle, much like a mirror. This single reflection provides information about the surface layer.

Understanding the Trade-offs

No single method is perfect for every application. Understanding their limitations is key to acquiring a good spectrum.

Transmission (KBr Pellets)

The primary drawback is the labor involved. Grinding the sample and pressing a good pellet takes time and skill.

Furthermore, KBr is highly hygroscopic (it readily absorbs water from the air), which can introduce large, unwanted water peaks into your spectrum if not handled carefully.

Attenuated Total Reflectance (ATR)

The main trade-off is that ATR is a surface technique. The IR beam only penetrates a few microns, so it may not represent the bulk material if the sample is heterogeneous.

Additionally, ATR spectra can have slight band shifts and intensity differences compared to traditional transmission spectra, which can be a factor in library matching.

Reflectance Methods

Reflectance spectra, particularly from DRIFTS and specular reflectance, can contain complex optical effects and scattering artifacts.

These often require specialized software corrections (like the Kubelka-Munk transformation for DRIFTS) to produce a spectrum that resembles a standard absorbance spectrum.

Making the Right Choice for Your Goal

Your choice of method should always be driven by the nature of your sample and the information you need.

- If your primary focus is a quick analysis of a solid or liquid: ATR is almost always the best starting point due to its speed and ease of use.

- If your primary focus is high-quality library matching or quantitative analysis of a solid powder: The KBr pellet method, while more difficult, often yields a superior, classic transmission spectrum.

- If your primary focus is a rough powder that cannot be pressed: DRIFTS is the designated technique for this type of sample.

- If your primary focus is a thin coating on a shiny metal surface: Specular reflectance is the only method designed specifically for this purpose.

Ultimately, matching the technique to the sample is the most important step in achieving a successful FTIR analysis.

Summary Table:

| Method | Best For | Key Advantage | Main Limitation |

|---|---|---|---|

| Transmission (KBr Pellet) | Solid Powders | High-quality spectra, ideal for library matching | Time-consuming; KBr is hygroscopic |

| Attenuated Total Reflectance (ATR) | Solids, Liquids, Pastes (Quick Analysis) | Minimal prep, fast, versatile | Surface analysis only (few microns) |

| Diffuse Reflectance (DRIFTS) | Rough Powders, Solids | No pressing required, good for difficult samples | Spectrum requires correction for artifacts |

| Specular Reflectance | Coatings on Reflective Surfaces | Direct analysis of surface layers | Limited to smooth, reflective surfaces |

Achieve Perfect FTIR Results with the Right Equipment from KINTEK

Selecting the correct sample preparation method is crucial for accurate FTIR analysis. KINTEK specializes in providing the high-quality lab equipment you need to execute these techniques effectively and efficiently.

We support your FTIR workflow with:

- Reliable Hydraulic Presses for creating consistent KBr pellets for transmission analysis.

- Durable ATR Accessories and crystals for fast, routine analysis with minimal sample prep.

Whether your lab focuses on pharmaceuticals, materials science, quality control, or academic research, having the right tools ensures reliable data. Let our experts help you optimize your FTIR sample preparation.

Contact us today to discuss your specific application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Warm Isostatic Press for Solid State Battery Research

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- How does a laboratory manual hydraulic press facilitate the FT-IR characterization of catalysts? Master Sample Prep.

- How do you prepare soil for XRF sample? A Step-by-Step Guide to Accurate Analysis

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- What is the use of hydraulic press in laboratory? Achieve Precise Sample Prep & Materials Testing

- What is the use of manual hydraulic press? A Cost-Effective Tool for Lab Sample Preparation