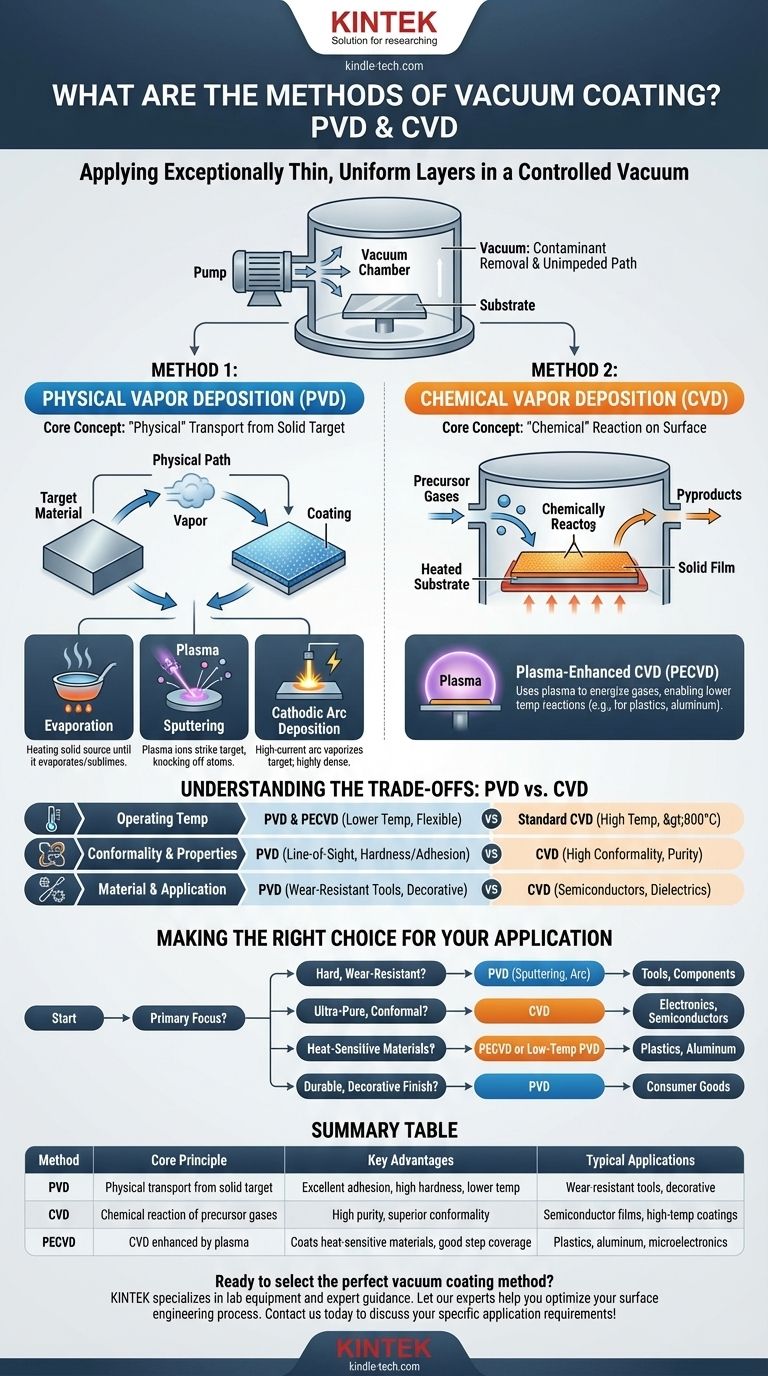

At its core, vacuum coating encompasses two primary families of methods: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). These processes operate within a vacuum to apply an exceptionally thin, uniform layer of material onto a substrate, fundamentally altering its surface properties for enhanced durability, functionality, or aesthetics. The choice between them depends entirely on the desired coating characteristics and the nature of the substrate material.

The fundamental difference lies in how the coating material reaches the target. Physical Vapor Deposition (PVD) physically transports atoms from a solid source to the substrate, while Chemical Vapor Deposition (CVD) uses chemical reactions from precursor gases to grow a film directly on the substrate's surface.

The Foundation: What is Vacuum Coating?

The Principle of Deposition

Vacuum coating, also known as thin-film deposition, is a high-technology process for applying a functional layer to a part. This coating is incredibly thin, often measured in microns or nanometers, but it provides significant protection against wear, friction, or environmental factors.

The entire process takes place inside a sealed vacuum chamber. This controlled environment is the key to the quality and consistency of the final coating.

Why a Vacuum is Essential

Creating a vacuum removes air, water vapor, and other atmospheric gases from the chamber. This is critical for two reasons. First, it eliminates contaminants that could otherwise react with the coating material and create impurities in the film.

Second, the near-absence of air molecules provides a clear, unimpeded path for the coating material to travel from its source to the substrate. This ensures an even, consistent, and strongly bonded deposition.

Method 1: Physical Vapor Deposition (PVD)

The Core Concept: "Physical" Transport

PVD processes take a solid source material—known as a "target"—and transform it into a vapor through purely physical means. This vapor then travels through the vacuum and condenses on the substrate, forming the coating. There is no intended chemical reaction in the core process.

Common PVD Techniques

PVD is not a single method but a family of related techniques. The most common include:

- Evaporation: This is the most straightforward PVD method. The source material is heated in a high vacuum until it evaporates (or sublimes), creating a vapor that coats the substrate. This heating can be done by passing a current through a resistive wire or by using a high-energy electron beam.

- Sputtering: In this process, the chamber is backfilled with a small amount of an inert gas, like argon. A high voltage is applied, creating a plasma. The positively charged gas ions are accelerated into the negatively charged target, striking it with enough force to physically "sputter" or knock off atoms, which then deposit onto the substrate.

- Cathodic Arc Deposition: This is a high-energy PVD variant where a high-current electric arc is used to vaporize the target material. This process creates a highly ionized vapor, resulting in extremely dense and well-adhered coatings.

Method 2: Chemical Vapor Deposition (CVD)

The Core Concept: A "Chemical" Reaction

Unlike PVD, CVD builds a coating through a chemical process. One or more volatile precursor gases are introduced into the vacuum chamber. These gases decompose and react on the heated surface of the substrate, forming a solid film of the desired material. The byproducts of the reaction are then pumped out of the chamber.

A Key Variation: Plasma-Enhanced CVD (PECVD)

Standard CVD processes often require very high temperatures (often >800°C) to drive the necessary chemical reactions. This limits their use to substrates that can withstand extreme heat.

Plasma-Enhanced CVD (PECVD) is an important evolution that uses a plasma to energize the precursor gases. This allows the chemical reactions to occur at much lower temperatures, making it possible to coat heat-sensitive materials like plastics and certain types of aluminum.

Understanding the Trade-offs: PVD vs. CVD

Choosing the right method involves balancing several key factors. There is no single "best" method; the optimal choice is entirely dependent on the application's requirements.

Operating Temperature

This is often the first consideration. Traditional CVD is a high-temperature process, unsuitable for materials with low melting points or those that could be damaged by heat. PVD and PECVD operate at significantly lower temperatures, offering much greater flexibility for coating polymers, aluminum alloys, and other heat-sensitive substrates.

Coating Properties and Conformality

CVD excels at producing highly pure, dense, and uniform films. Because it involves a gas that can flow everywhere, it is exceptional at coating complex, non-line-of-sight geometries, a property known as high "conformality."

PVD is a line-of-sight process, which can make it challenging to coat complex internal surfaces. However, methods like sputtering and cathodic arc produce coatings with outstanding hardness and adhesion due to the high kinetic energy of the depositing atoms.

Material and Application

The desired coating material often dictates the process. CVD is the dominant method for producing many of the high-purity silicon and dielectric films essential to the semiconductor industry. PVD is extremely versatile and widely used for applying hard, wear-resistant coatings (like Titanium Nitride) on cutting tools, as well as for decorative metallic finishes on consumer products.

Making the Right Choice for Your Application

Ultimately, the selection of a vacuum coating method is a technical decision driven by the end goal.

- If your primary focus is hard, wear-resistant coatings on metal tools or components: PVD methods like sputtering or cathodic arc deposition are typically the superior choice for their excellent adhesion and durability.

- If your primary focus is ultra-pure, highly conformal films for electronics or semiconductors: CVD is the established industry standard due to its ability to grow flawless layers from chemical precursors.

- If your primary focus is coating heat-sensitive materials like plastic or aluminum: PECVD or a low-temperature PVD process is the necessary solution to avoid damaging the substrate.

- If your primary focus is a durable, decorative metallic finish on consumer goods: PVD is the most common and cost-effective method for achieving a wide range of colors and finishes.

By understanding the fundamental principles of physical transport versus chemical reaction, you can confidently navigate the landscape of vacuum coating and select the process that best aligns with your technical objectives.

Summary Table:

| Method | Core Principle | Key Advantages | Typical Applications |

|---|---|---|---|

| Physical Vapor Deposition (PVD) | Physical transport of atoms from a solid target to the substrate. | Excellent adhesion, high hardness, lower temperature process. | Wear-resistant tool coatings, decorative finishes. |

| Chemical Vapor Deposition (CVD) | Chemical reaction of precursor gases on the substrate surface. | High purity, superior conformality on complex shapes. | Semiconductor films, high-temperature coatings. |

| Plasma-Enhanced CVD (PECVD) | CVD process enhanced by plasma for lower temperature reactions. | Coats heat-sensitive materials, good step coverage. | Coatings on plastics, aluminum, microelectronics. |

Ready to select the perfect vacuum coating method for your project? The choice between PVD and CVD is critical for achieving the desired hardness, purity, and durability for your components. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance on deposition technologies. Let our experts help you optimize your surface engineering process. Contact us today to discuss your specific application requirements!

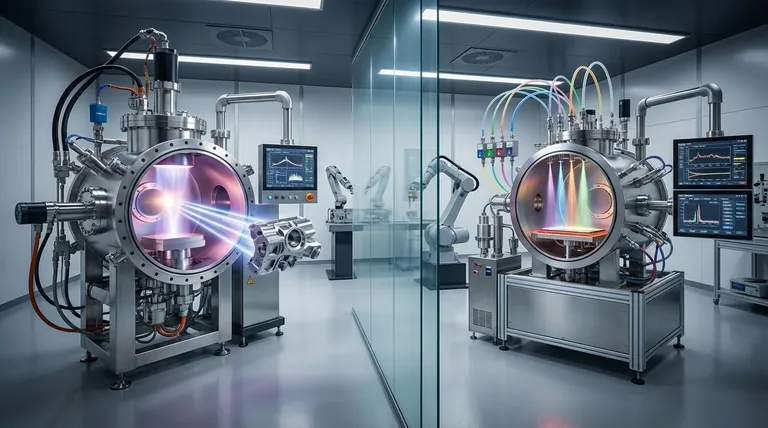

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication