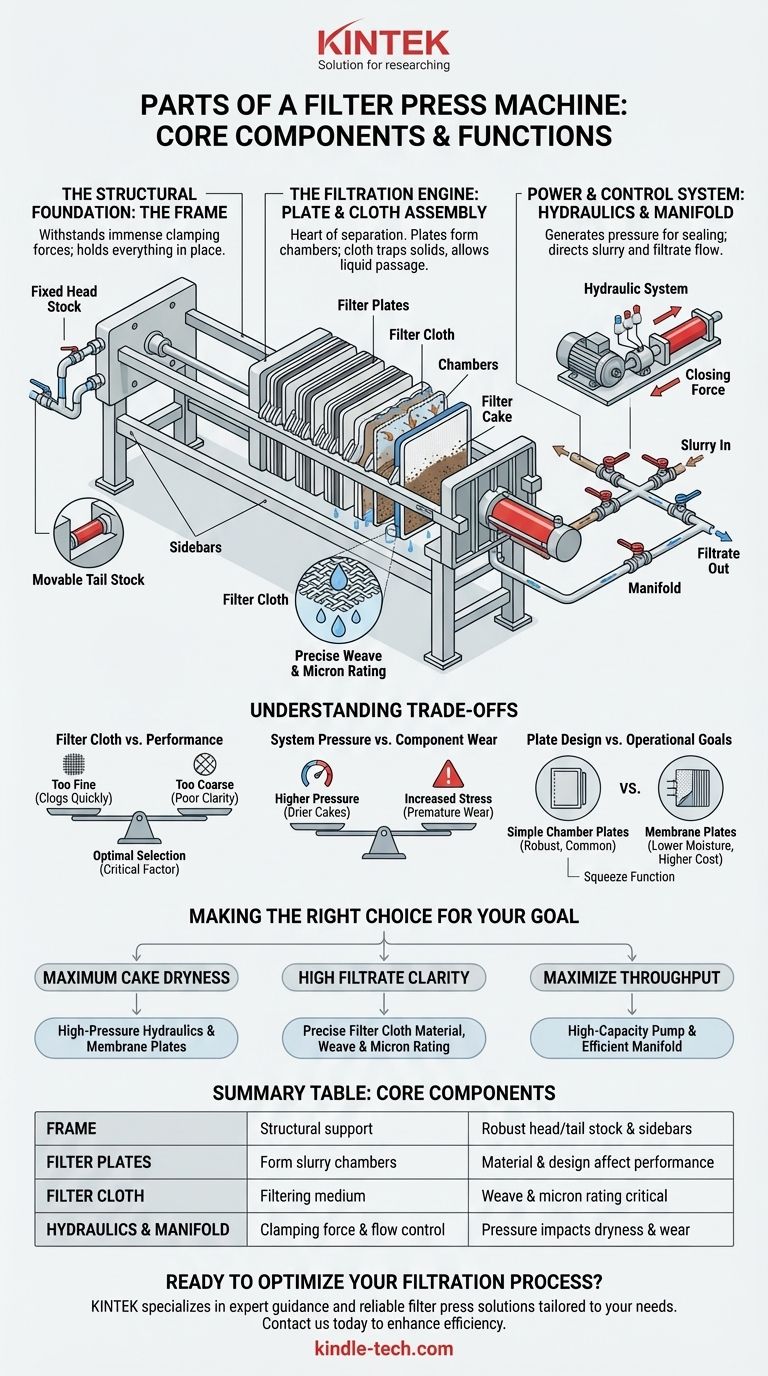

At its core, a filter press machine consists of four primary components: the frame, the filter plates, the manifold, and the filter cloth. These structural and filtering elements are activated by a power system, typically hydraulic, which generates the immense pressure required for effective solid-liquid separation.

A filter press is fundamentally a straightforward mechanical system. It uses a robust frame and immense hydraulic pressure to compress a stack of cloth-covered plates, physically squeezing liquid out of a slurry and leaving solid "cakes" behind. Understanding each component's role is key to optimizing its performance.

The Structural Foundation: The Frame

The frame is the skeleton of the machine, engineered to withstand the massive clamping forces generated during a press cycle. Its sole purpose is to hold everything in place under extreme pressure without flexing or failing.

The Head and Tail Stock

The frame consists of a fixed head stock and a movable tail stock. The head stock is stationary and contains the piping connections for the slurry and filtrate, while the tail stock houses the hydraulic cylinder that provides the closing force.

The Sidebars

Two heavy-duty sidebars connect the head and tail stock. These bars not only provide the structural integrity of the frame but also serve as the rails on which the filter plates hang and slide.

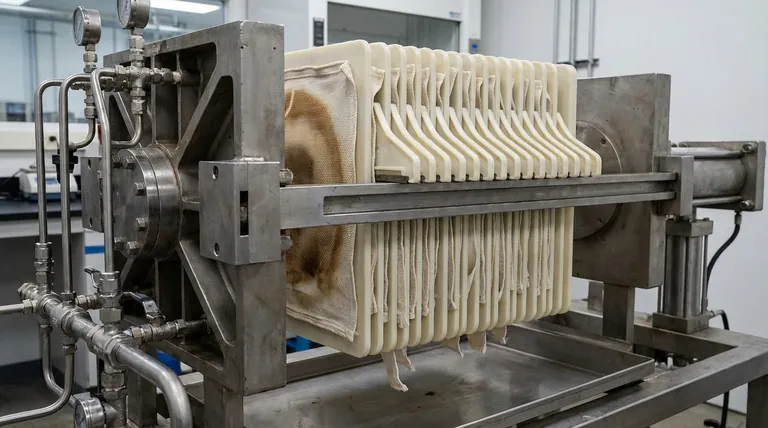

The Filtration Engine: The Plate and Cloth Assembly

This is the heart of the filter press where the actual separation occurs. The combination of plates and cloth creates a series of chambers that contain the slurry and filter the liquid.

The Filter Plates

Filter plates are the core components that form the filter pack. When pressed together, their surfaces create hollow chambers that are filled with the slurry. They are typically made of durable materials like polypropylene.

The Filter Cloth

The filter cloth is the true filtering medium. Each plate is dressed with a sheet of this specially woven fabric. The cloth's weave and material are precisely chosen for a specific application to allow liquid (filtrate) to pass through while retaining the solid particles.

How They Work Together

Slurry is pumped into the chambers between the cloth-covered plates. The hydraulic system clamps the plates together, and the pressure forces the liquid through the filter cloth. The solids are trapped on the cloth's surface, gradually building up to form a dense "filter cake."

The Power and Control System: Hydraulics and Manifold

This system provides the force and the flow control needed to operate the machine efficiently. It dictates how quickly the press can be filled, how much pressure is applied, and how the resulting liquid is discharged.

The Hydraulic System

The hydraulic system is the machine's power source. It consists of an electric motor, a hydraulic pump, a cylinder, and controls. This system is responsible for opening and, more importantly, closing the press with enough force to seal the plates and dewater the slurry.

The Manifold

The manifold is the integrated network of piping and valves. It directs the flow of slurry into the press and channels the clean filtrate out. A well-designed manifold ensures all chambers fill evenly and efficiently.

Understanding the Trade-offs

Choosing and maintaining these components involves balancing competing operational goals. An incorrect choice in one area will negatively impact the entire system's performance.

Filter Cloth vs. Performance

The selection of the filter cloth is the single most critical factor for optimizing performance. A cloth that is too fine can "blind" or clog quickly, while a cloth that is too coarse will allow solids to pass through, resulting in poor filtrate clarity.

System Pressure vs. Component Wear

Higher hydraulic pressure results in drier filter cakes, which is often desirable. However, operating at maximum pressure increases stress on the frame, plates, and cloth, potentially leading to premature wear and higher maintenance costs.

Plate Design vs. Operational Goals

Simple chamber plates are robust and common, but specialized membrane plates offer a secondary "squeeze" function. These inflatable plates can achieve significantly lower moisture content in the final cake but add complexity and cost to the system.

Making the Right Choice for Your Goal

The ideal configuration of a filter press depends entirely on your primary objective.

- If your primary focus is achieving maximum cake dryness: Prioritize a high-pressure hydraulic system and consider investing in membrane filter plates.

- If your primary focus is ensuring high filtrate clarity: Your most critical decision will be the precise material, weave, and micron rating of your filter cloth.

- If your primary focus is maximizing throughput and processing speed: Focus on a high-capacity pump and an efficiently designed manifold for rapid fill and discharge cycles.

Understanding how these core components interact empowers you to operate, troubleshoot, and optimize your filtration process effectively.

Summary Table:

| Component | Primary Function | Key Considerations |

|---|---|---|

| Frame | Provides structural support to withstand high pressure. | Includes head/tail stock and sidebars; must be robust. |

| Filter Plates | Form hollow chambers that hold the slurry for filtration. | Material (e.g., polypropylene) and design (e.g., membrane plates) affect performance. |

| Filter Cloth | The actual filtering medium that separates solids from liquid. | Weave and micron rating are critical for clarity and preventing clogging. |

| Hydraulic System & Manifold | Generates clamping force and controls slurry/filtrate flow. | Pressure settings impact cake dryness and component wear. |

Ready to optimize your filtration process? The right configuration of these components is key to achieving your goals for cake dryness, filtrate clarity, and throughput. KINTEK specializes in lab equipment and consumables, offering expert guidance and reliable filter press solutions tailored to your laboratory's specific needs. Contact us today to discuss how we can enhance your solid-liquid separation efficiency!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What role does a laboratory hydraulic press play in pellet-type electrode fabrication? Enhancing Solid-State Performance

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How is a hydraulic press helpful for making KBr pellets? Achieve Superior FTIR Sample Preparation