In short, a hydraulic press is essential for making high-quality KBr pellets because it applies the immense, uniform pressure needed to transform the powdered sample mixture into a solid, glass-like disc. This process is critical for removing microscopic air pockets and adsorbed moisture, both of which can severely degrade the quality of an FTIR spectrum.

The core function of the hydraulic press in FTIR sample preparation is not simply to compact powder. It is to create an optically transparent window that minimizes light scattering and eliminates interfering signals, thereby ensuring the final spectrum accurately represents the chemical makeup of your sample.

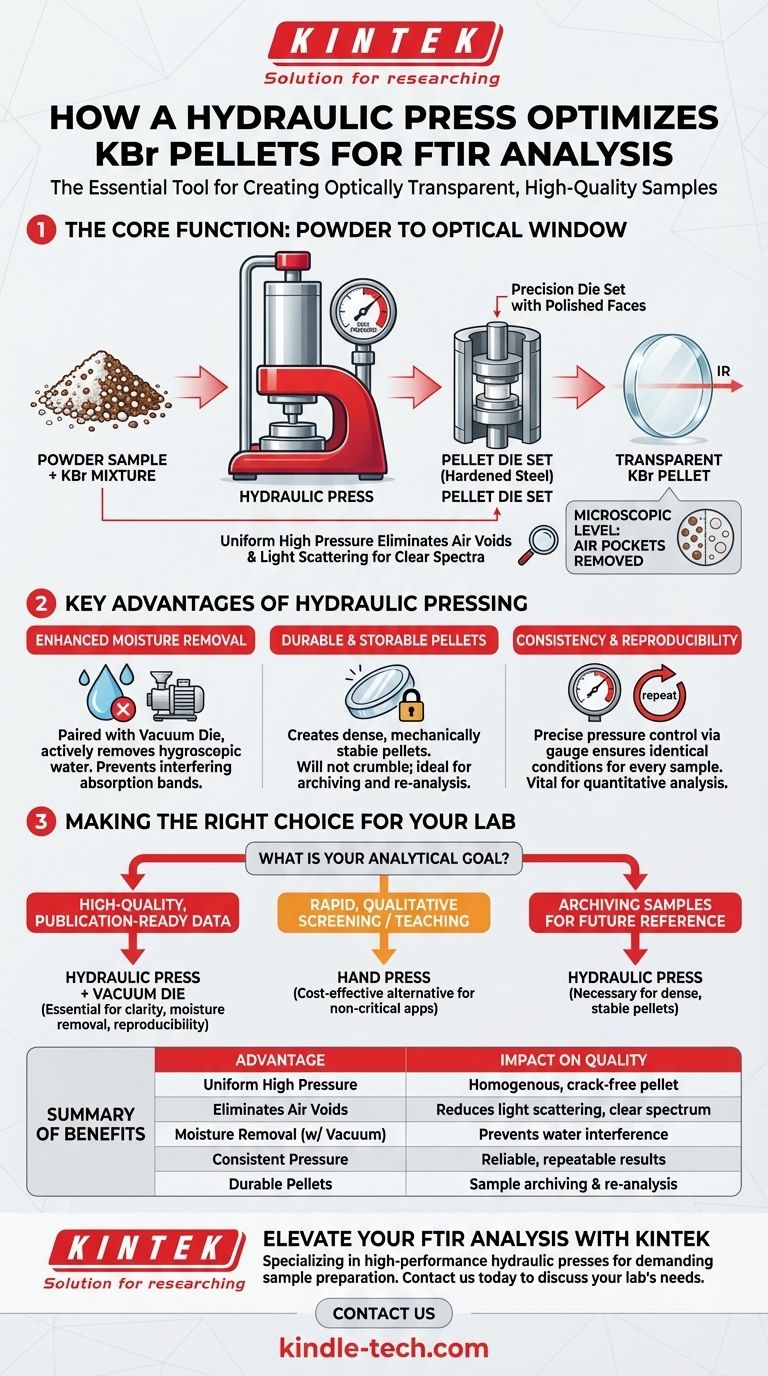

The Core Function: From Powder to Optical Window

The goal of creating a KBr pellet is to suspend a solid sample within an infrared-transparent matrix. The hydraulic press is the tool that makes this transformation possible by applying controlled, high pressure.

Achieving Uniform High Pressure

A hydraulic press operates on Pascal's principle, using fluid to convert a small amount of applied force into a massive, evenly distributed pressure across the entire surface of the pellet die. This uniformity is crucial for creating a homogenous pellet free of cracks or weak points.

Eliminating Voids and Light Scattering

When KBr and your sample are ground together, the resulting powder is full of air. If not removed, these tiny air pockets will scatter the instrument's IR beam. This scattering leads to a sloping, noisy baseline and reduced signal intensity in your spectrum, making it difficult to interpret. The high pressure from the press physically forces the KBr particles together, eliminating these voids.

The Critical Role of the Die Set

The press itself only provides force. The quality of the final pellet depends on the pellet die set—a hardened steel or alloy cylinder and pistons. The press applies force to this die, which in turn compresses the powder. The optically polished faces of the die impart a smooth, glass-like surface onto the pellet, further reducing light scatter.

Why a Hydraulic Press is Superior for Critical Analysis

While simple hand presses exist, a hydraulic press is the standard for any application requiring reliable, high-quality data. Its advantages are directly linked to solving the most common problems in KBr pellet preparation.

Enhanced Moisture Removal

KBr is highly hygroscopic, meaning it readily absorbs water from the atmosphere. This is a major problem, as water has very strong absorption bands in the infrared spectrum that can obscure the peaks from your actual sample. Many hydraulic press systems are designed to be used with a vacuum die, which allows you to pull a vacuum while the sample is under pressure, actively removing this interfering moisture.

Creating Durable, Storable Pellets

The immense pressure (often several tons) applied by a hydraulic press creates a much denser and more mechanically stable pellet than a hand press can. These robust pellets will not easily crumble, allowing them to be stored for future reference or re-analysis.

Consistency and Reproducibility

Most hydraulic presses are equipped with a pressure gauge. This allows you to apply the exact same pressure for every sample you prepare. This consistency is vital for reproducible experiments, especially in quantitative analysis where pellet thickness and density must be uniform.

Understanding the Trade-offs

A hydraulic press is the superior tool for high-quality FTIR analysis, but it is not the only option. Understanding its context is key to making an informed decision for your lab.

When a Hand Press Might Suffice

For quick qualitative checks, teaching laboratories, or situations where perfect spectral quality is not the primary goal, a manual hand press can be a suitable choice. They are simpler, more portable, and less expensive. However, they are not ideal for removing moisture or creating durable pellets.

Cost and Lab Space

Hydraulic presses are significantly larger, heavier, and more expensive than hand presses. They are a piece of capital equipment that requires dedicated bench space and occasional maintenance, which must be factored into any lab budget.

The Importance of Proper Technique

The press is a powerful tool, but it does not guarantee a perfect result on its own. The final pellet quality is still highly dependent on user technique, including the proper grinding of the KBr/sample mixture and applying the correct amount of pressure without cracking the pellet or damaging the die.

Making the Right Choice for Your Analysis

Your choice of equipment should be driven by the specific requirements of your analytical goal.

- If your primary focus is high-quality, publication-ready data: A hydraulic press, ideally paired with a vacuum die, is essential for achieving the necessary clarity, moisture removal, and reproducibility.

- If your primary focus is rapid, qualitative screening or teaching: A manual hand press is a cost-effective and perfectly viable alternative for non-critical applications.

- If your primary focus is archiving samples for future reference: The hydraulic press is necessary to create the dense, mechanically stable pellets required for long-term storage.

Ultimately, choosing the right pressing method is the first step toward ensuring the integrity and accuracy of your spectroscopic data.

Summary Table:

| Hydraulic Press Advantage | Impact on KBr Pellet Quality |

|---|---|

| Uniform High Pressure | Creates a homogenous, crack-free pellet |

| Eliminates Air Voids | Reduces light scattering for a clear FTIR spectrum |

| Moisture Removal (with Vacuum Die) | Prevents water interference in spectral data |

| Consistent, Reproducible Pressure | Ensures reliable, repeatable experimental results |

| Durable, Storable Pellets | Allows for sample archiving and future re-analysis |

Ready to elevate your FTIR analysis with professional-grade KBr pellets?

KINTEK specializes in providing high-performance hydraulic presses and laboratory equipment designed specifically for demanding sample preparation tasks like yours. Our solutions ensure you achieve the clarity, consistency, and accuracy required for critical spectroscopic data.

Contact us today using the form below to discuss how our expertise and products can support your laboratory's success. Let's ensure your next analysis is a resounding success.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the function of a laboratory hydraulic press during the fabrication of Beta-Al2O3 solid electrolyte pellets?

- Why is a laboratory hydraulic press used for MOF-CGC pellets? Maximize Density and Encapsulation Quality

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- What is the role of a laboratory hydraulic press in sulfide solid-state electrolyte pellet formation? Maximize Density