The physical properties of sinter are not a fixed set of values but are intentionally engineered characteristics designed to optimize blast furnace performance. The most critical properties are its strength, its reducibility by hot gases, and its behavior at high temperatures. These are determined by the sinter's chemical composition and the specific conditions of the sintering process itself.

Sinter should not be viewed as a simple raw material, but as a complex, engineered composite. Its physical properties are deliberately manipulated through chemical adjustments and process control to maximize the efficiency and stability of iron production.

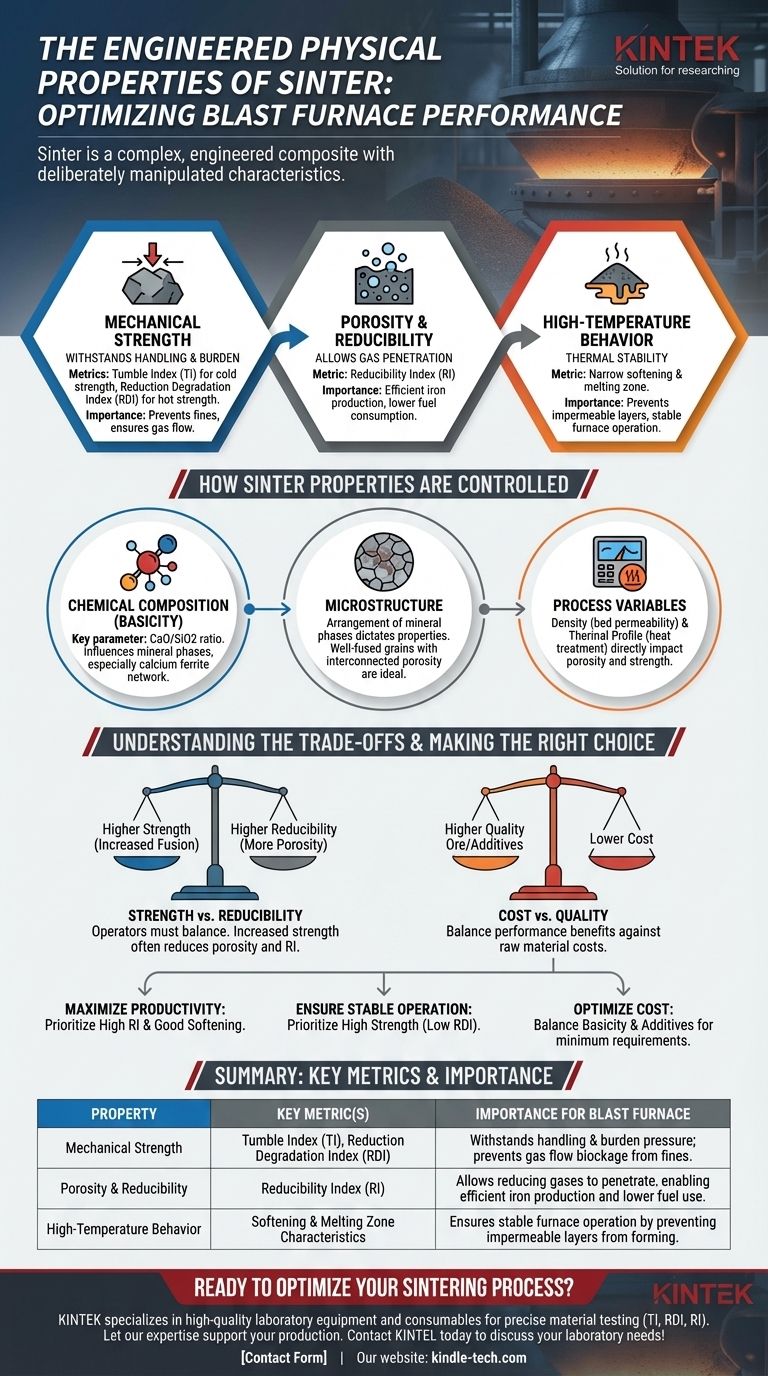

The Core Physical Properties of Sinter

The goal of sintering is to create a material that survives transport, performs predictably inside the blast furnace, and allows for efficient iron ore reduction. The following properties are how we measure that success.

Mechanical Strength

Sinter must be strong enough to withstand handling, transportation, and the immense weight of the material column (the "burden") inside the blast furnace without breaking down into fine particles, which would choke the gas flow.

Strength is measured in two key ways:

- Tumble Index (TI): This measures the sinter's cold strength and its resistance to degradation during handling and charging into the furnace.

- Reduction Degradation Index (RDI): This measures the sinter's hot strength, or its tendency to break down at the high temperatures and reducing atmosphere found in the upper part of the blast furnace.

Porosity and Reducibility

For iron to be produced, reducing gases (like carbon monoxide) must penetrate the sinter and react with the iron oxides. High reducibility is essential for furnace efficiency and lower fuel consumption.

This is governed by the sinter's porosity, which creates pathways for the gas. The Reducibility Index (RI) is the standard measure of how easily and completely the iron oxides within the sinter can be converted to metallic iron.

High-Temperature Behavior

As the sinter descends into the hotter zones of the blast furnace, its thermal stability becomes critical. The key is to have a narrow softening and melting zone.

If sinter softens too early or over too wide a temperature range, it can form an impermeable layer that obstructs gas flow, leading to unstable furnace operation.

How Sinter Properties Are Controlled

The physical properties described above are not accidental. They are the direct result of careful control over the material's chemistry and its formation process.

The Role of Chemical Composition (Basicity)

The single most important chemical parameter is basicity, typically defined as the weight ratio of calcium oxide (CaO) to silicon dioxide (SiO2).

Adjusting the basicity has a profound effect on the mineral phases that form during sintering. Key phases include hematite, magnetite, and, critically, various forms of calcium ferrite.

The formation of a strong, interconnected network of calcium ferrites is highly desirable, as it simultaneously improves both strength and reducibility.

The Impact of Microstructure

The type and arrangement of these mineral phases create the sinter's microstructure. This internal structure is what ultimately dictates the final physical properties.

A good microstructure consists of well-fused mineral grains with sufficient interconnected porosity. It is the physical manifestation of the chemistry and process conditions.

The Influence of Process Variables

The properties of the final sinter are also directly manipulated by the sintering process itself.

Variations in density (controlled by the permeability of the raw material bed) and the thermal profile (a form of heat treatment) determine which mineral phases form and how they fuse together, directly impacting porosity and strength.

Understanding the Trade-offs

Optimizing sinter is a constant balancing act. Improving one property can often have a negative impact on another.

Strength vs. Reducibility

This is the classic trade-off in sinter production. Actions taken to increase strength, such as increasing fusion or density, typically reduce the sinter's porosity.

Reduced porosity makes it harder for reducing gases to penetrate the material, which lowers the Reducibility Index (RI). Operators must find the optimal balance for their specific furnace requirements.

Cost vs. Quality

Achieving ideal sinter properties often requires the use of higher-quality iron ores or specific additives, which increases the overall cost of the hot metal produced.

Plant metallurgists must constantly weigh the performance benefits of a higher-quality sinter against the economic realities of raw material costs.

Making the Right Choice for Your Goal

The "best" sinter properties depend entirely on your operational strategy for the blast furnace.

- If your primary focus is maximizing furnace productivity: Prioritize a high Reducibility Index (RI) and good softening-melting characteristics to enable a higher production rate and lower fuel consumption.

- If your primary focus is ensuring stable furnace operation: Prioritize high strength, especially a low Reduction Degradation Index (RDI), to minimize the generation of fine particles that can disrupt gas flow.

- If your primary focus is optimizing cost: Carefully balance the use of basicity adjustments and additives to produce a sinter that meets the minimum required strength and reducibility targets without over-engineering it.

Ultimately, sinter is a sophisticated material designed to solve a specific engineering problem within the blast furnace.

Summary Table:

| Property | Key Metric(s) | Importance for Blast Furnace |

|---|---|---|

| Mechanical Strength | Tumble Index (TI), Reduction Degradation Index (RDI) | Withstands handling & burden pressure; prevents gas flow blockage from fines. |

| Porosity & Reducibility | Reducibility Index (RI) | Allows reducing gases to penetrate, enabling efficient iron production and lower fuel use. |

| High-Temperature Behavior | Softening & Melting Zone Characteristics | Ensures stable furnace operation by preventing impermeable layers from forming. |

Ready to Optimize Your Sintering Process?

Understanding and controlling sinter properties is key to maximizing blast furnace performance. KINTEK specializes in providing high-quality laboratory equipment and consumables for precise material testing and analysis. Whether you need to measure Tumble Index (TI), Reduction Degradation Index (RDI), or Reducibility Index (RI), our robust and reliable solutions help you achieve the perfect balance of strength, reducibility, and cost-efficiency for your specific operational goals.

Let our expertise support your production. Contact KINTEL today to discuss your laboratory needs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the factors affecting the sintering process? Master the 5 Key Factors for Perfect Sintering

- What is too high for sintering temperature? Avoid Material Degradation and Optimize Your Process

- What is vacuum heat treating? Achieve Superior Metallurgical Purity and Surface Integrity

- What are the uses of furnace in industry? Powering Material Transformation and Manufacturing

- What is the purpose of using a high-temperature sintering furnace for post-annealing NASICON? Enhance Ionic Conductivity

- What are the applications of brazing? Join Dissimilar Metals & Create Leak-Proof Seals

- What is a furnace used for sintering? Creating High-Performance Solid Components from Powder

- What is the requirement of heat treatment? Unlock Your Material's Full Potential