Preventive maintenance for a hydraulic press is a systematic schedule of inspections, servicing, and part replacements designed to prevent unexpected failures. The core of this process involves maintaining the health of the hydraulic fluid, ensuring the integrity of mechanical and electrical components, and keeping the machine clean and properly lubricated.

The goal of preventive maintenance is to shift from a reactive mindset (fixing breakdowns) to a proactive one (preventing them). A consistent program focused on fluid health, structural integrity, and safety checks is the most effective way to ensure reliability, avoid costly downtime, and extend the life of your machine.

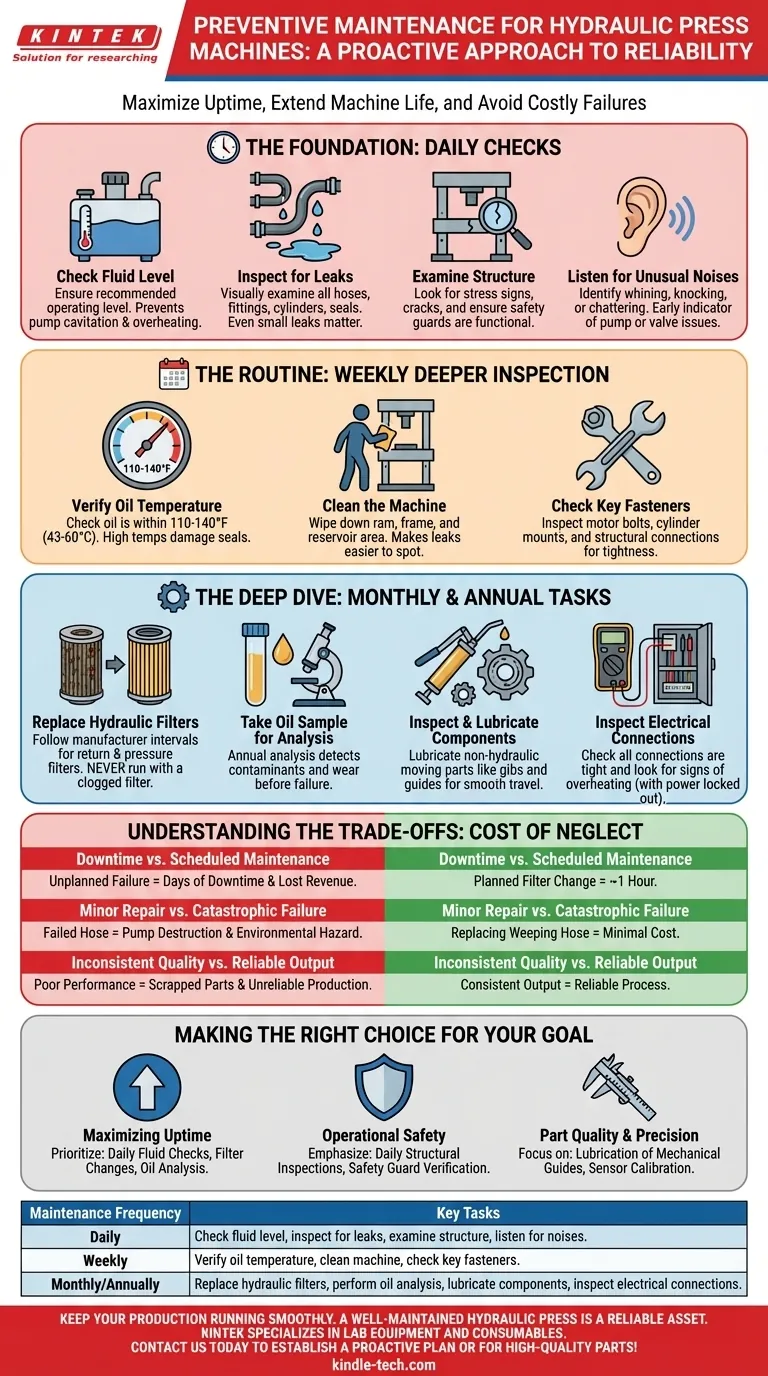

The Foundation: Daily Checks

The daily walk-around inspection is your first line of defense. These simple, quick checks can identify developing issues before they escalate into major problems.

Check Hydraulic Fluid Level

The hydraulic reservoir should have a sight glass or dipstick. Ensure the fluid is at the recommended operating level. Low fluid levels can cause the pump to cavitate (draw in air), leading to overheating and severe damage.

Inspect for Fluid Leaks

Visually inspect all hoses, fittings, cylinders, and seals. Even a small leak is a significant issue, indicating a failing component and creating a potential entry point for contamination. Leaks are also a safety and fire hazard.

Examine the Machine Structure

Look for any signs of stress, such as cracks in welds or the frame. Check that all guards and safety devices are in place and functioning correctly. Ensure the bed and ram are clear of any debris.

Listen for Unusual Noises

Start the machine and listen. A healthy hydraulic pump has a consistent hum. Any new or unusual noises, like whining, knocking, or chattering, are early indicators of problems with the pump, valves, or aeration in the system.

The Weekly Routine: Deeper Inspection

Weekly tasks build on the daily checks, requiring a slightly more detailed look at key systems.

Verify Oil Temperature

Most systems have a temperature gauge. Check that the oil is operating within its recommended range, typically 110-140°F (43-60°C). Consistently high temperatures break down the oil and damage seals.

Clean the Machine

Wipe down the ram, frame, and the area around the hydraulic reservoir. A clean machine makes it easier to spot leaks and other issues. Dirt and grime can also damage seals and wear surfaces.

Check Key Fasteners

Vibration can cause critical bolts and fasteners to loosen over time. Check the motor mounting bolts, cylinder mounts, and any other major structural connections to ensure they are secure.

The Monthly & Annual Deep Dive

These more intensive tasks form the backbone of your long-term reliability strategy and may require a scheduled shutdown.

Replace Hydraulic Filters

Filters are critical for removing contaminants that cause wear on pumps, valves, and cylinders. Follow the manufacturer's recommended replacement interval for both the return line and pressure filters. Never run a press with a clogged filter.

Take an Oil Sample for Analysis

Annual oil analysis is like a blood test for your machine. A lab can analyze a small sample to detect contaminants, fluid degradation, and the presence of microscopic metal particles, which indicate internal component wear long before failure occurs.

Inspect and Lubricate Mechanical Components

Check and lubricate all non-hydraulic moving parts, such as gibs and guides on the ram. Proper lubrication ensures smooth, precise travel and prevents premature wear.

Inspect Electrical Connections

With the power locked out, open the main electrical cabinet and check that all connections are tight. Look for any signs of overheating, such as discolored wires or terminals, which could indicate a loose connection and a fire hazard.

Understanding the Trade-offs: The Cost of Neglect

Ignoring preventive maintenance is a choice with significant consequences. Understanding the trade-offs makes the value of a proactive approach clear.

Downtime vs. Scheduled Maintenance

A planned filter change might take an hour. An unplanned pump failure caused by a clogged filter can shut down production for days while you wait for parts and service, costing thousands in lost revenue.

Minor Repair vs. Catastrophic Failure

Replacing a weeping hydraulic hose costs very little. Letting it fail can drain the reservoir, destroy the pump from fluid starvation, and create a massive environmental and safety incident.

Inconsistent Quality vs. Reliable Output

A press with low fluid, overheating oil, or worn guides will not perform consistently. This leads to scrapped parts, increased setup times, and an unreliable production process.

Making the Right Choice for Your Goal

Tailor your maintenance focus to your most critical operational priorities.

- If your primary focus is maximizing uptime: Prioritize daily fluid checks and a strict schedule for filter changes and oil analysis to prevent the most common and severe failures.

- If your primary focus is operational safety: Emphasize daily structural inspections and regular verification of all safety guards, light curtains, and emergency stop circuits.

- If your primary focus is part quality and precision: Focus on the regular lubrication of mechanical guides and the calibration of pressure and position sensors.

A proactive maintenance program transforms your hydraulic press from a potential liability into a consistently reliable production asset.

Summary Table:

| Maintenance Frequency | Key Tasks |

|---|---|

| Daily | Check fluid level, inspect for leaks, examine structure, listen for unusual noises. |

| Weekly | Verify oil temperature, clean machine, check key fasteners. |

| Monthly/Annually | Replace hydraulic filters, perform oil analysis, lubricate components, inspect electrical connections. |

Keep your production running smoothly and avoid costly downtime. A well-maintained hydraulic press is a reliable asset. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you establish a proactive maintenance plan or provide the high-quality parts you need. Contact us today to ensure your hydraulic press operates at peak performance!

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- How does a heated laboratory hydraulic press facilitate densification in CSP? Optimize Mg-doped NASICON Sintering

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance