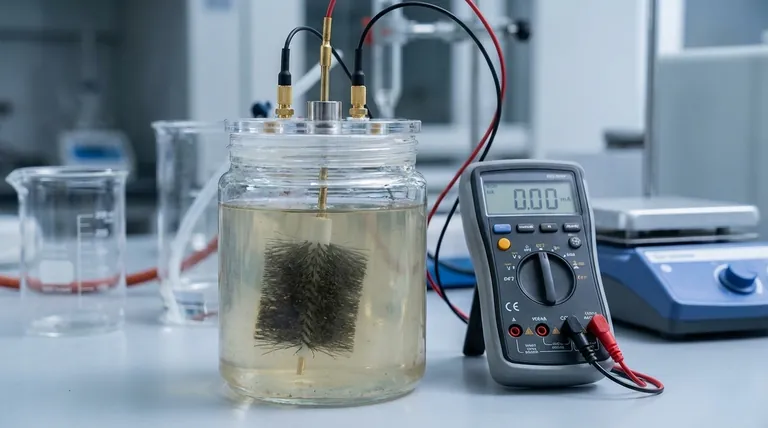

In experimental science, the primary application of carbon fiber brushes is to serve as high-performance anodes in microbial electrochemical tests. Their excellent electrical conductivity and physical stability make them an ideal material for cultivating microbial biofilms and efficiently harvesting the electrons these microbes produce.

The core value of a carbon fiber brush is not just its material composition, but its function as a superior bio-interface. It creates an optimal environment for microbial colonization while ensuring the stable and efficient transfer of biological energy into a measurable electrical current.

The Core Function: Anodes in Bioelectrochemical Systems

Carbon fiber brushes are a foundational component in experiments like microbial fuel cells (MFCs) or microbial electrolysis cells (MECs). Their design and material properties are engineered specifically for this purpose.

The Material Advantage

A carbon fiber brush is typically constructed from two key materials: high-quality carbon fiber filaments and a high-purity titanium wire core.

Each component serves a critical role. The carbon fiber provides excellent conductivity and a large surface area, while the titanium wire offers high strength and chemical stability.

This combination ensures the brush performs reliably even in the complex and often corrosive chemical environments of a bioreactor.

Facilitating Microbial Biofilm Growth

The dense bristles of the brush create an enormous surface area. This structure is ideal for the cultivation of microbes, allowing them to attach and form a thriving biofilm.

A healthy, dense biofilm on the anode is essential for the success of any microbial electrochemical experiment.

The Critical Role of Conductivity

The primary job of the anode is to collect electrons generated by the microbes. The excellent conductivity of the carbon fiber is what makes the brush so effective.

It allows electrons to move from the microbial biofilm to the external circuit with minimal resistance, maximizing the efficiency and accuracy of the experiment.

Common Pitfalls and Operational Checks

Using carbon fiber brushes effectively requires more than just proper installation. It demands careful monitoring to ensure the system is functioning as intended.

Monitoring Key Parameters

During any experiment, it is crucial to closely monitor electrical outputs, specifically current and voltage. These parameters are direct indicators of the system's biological and electrochemical health.

Troubleshooting Low Current Output

An abnormally low or declining current is a clear signal that something is wrong. This issue often points to one of two common problems.

First, it may indicate poor microbial film growth, meaning the biological component of the system is not thriving.

Second, it could be a sign of inadequate electrode contact, a physical problem where the brush is not properly connected to the circuit, preventing efficient electron flow. Prompt investigation is necessary to resolve these issues and ensure data integrity.

Summary Table:

| Key Application | Core Function | Material Advantage |

|---|---|---|

| Anode in Microbial Fuel Cells (MFCs) | Cultivate microbial biofilms & harvest electrons | High conductivity carbon fiber & titanium core |

| Anode in Microbial Electrolysis Cells (MECs) | Ensure stable electron transfer in bioreactors | Large surface area for microbial colonization |

| Bioelectrochemical System Testing | Monitor current/voltage for experimental accuracy | Durable in corrosive chemical environments |

Optimize Your Bioelectrochemical Experiments with KINTEK

Are you setting up a microbial fuel cell or electrolysis cell? The right anode is critical for success. KINTEK specializes in high-performance carbon fiber brushes designed to maximize microbial biofilm growth and ensure efficient electron harvesting. Our brushes, featuring high-purity carbon fiber and titanium cores, provide the reliability and conductivity your lab demands.

Let us help you achieve accurate and reproducible results. Contact our experts today to discuss your specific application and find the perfect lab equipment solution.

Visual Guide

Related Products

- Glassy Carbon Electrochemical Electrode

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What is the typical working electrode potential range for a glassy carbon electrode in aqueous electrolytes? A Guide to Accurate Electrochemical Measurements

- How to make a glassy carbon electrode? A Guide to the Industrial Pyrolysis Process

- Why is a glassy carbon disc electrode an indispensable consumable? Ensure Reliable Catalyst Evaluation Today

- What is a glassy carbon electrode made of? The Engineered Material Powering Electrochemical Analysis

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy