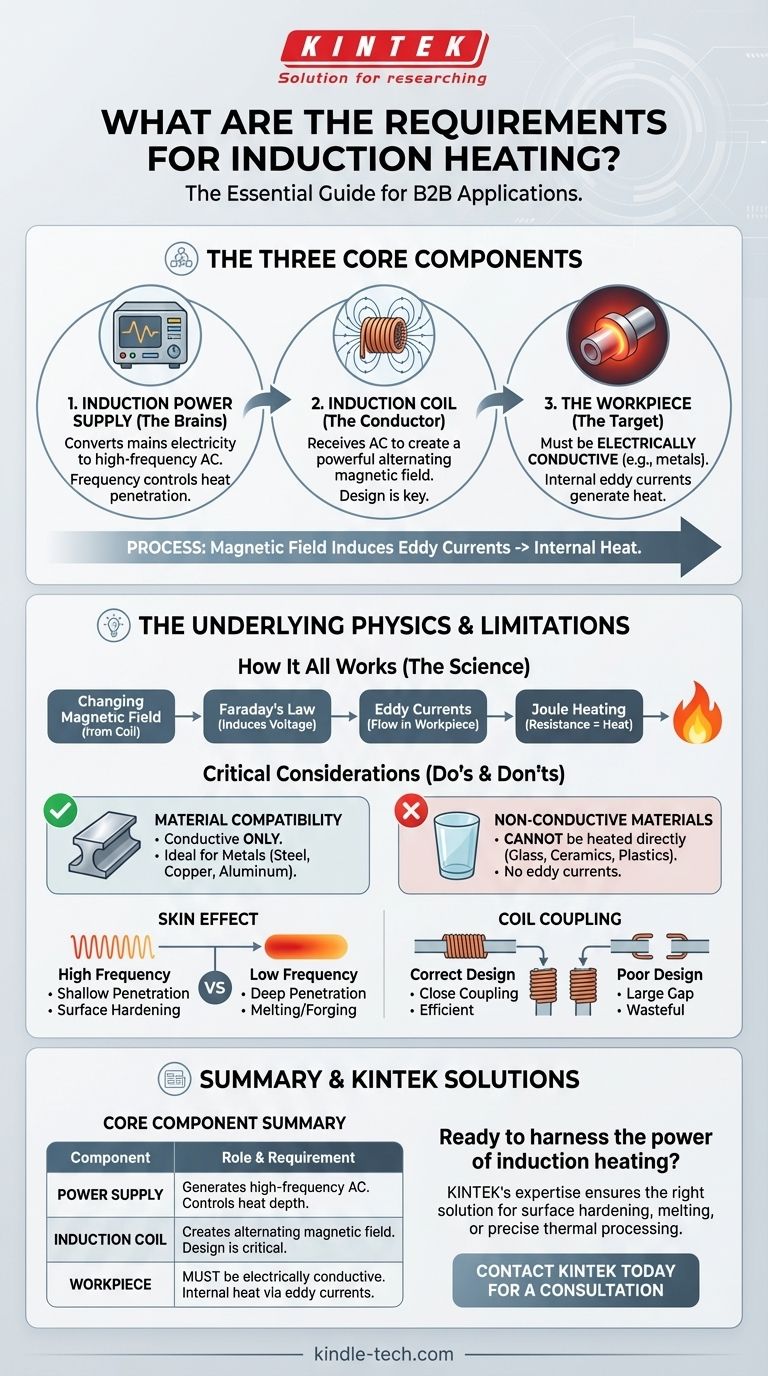

To put it simply, induction heating requires three core components: a power supply that generates a high-frequency alternating current, an induction coil to create a magnetic field, and a workpiece made of an electrically conductive material. The process works by using the magnetic field to induce electrical currents inside the workpiece itself, which in turn generates precise and rapid heat.

The fundamental requirement for induction heating isn't about applying external heat; it's about using a magnetic field to turn the object you want to heat into its own internal heat source. This is only possible if the object can conduct electricity.

The Core Components of an Induction System

For induction heating to occur, a complete system must be in place. Each component plays a distinct and critical role in the process.

The Induction Power Supply (The Brains)

The process begins with the induction power supply. Its job is to convert standard mains electricity (e.g., 50/60 Hz) into a high-frequency alternating current (AC).

The frequency is a critical parameter. Different frequencies control how deeply the heat penetrates the workpiece, making the power supply essential for tailoring the heating effect to a specific application.

The Induction Coil (The Conductor)

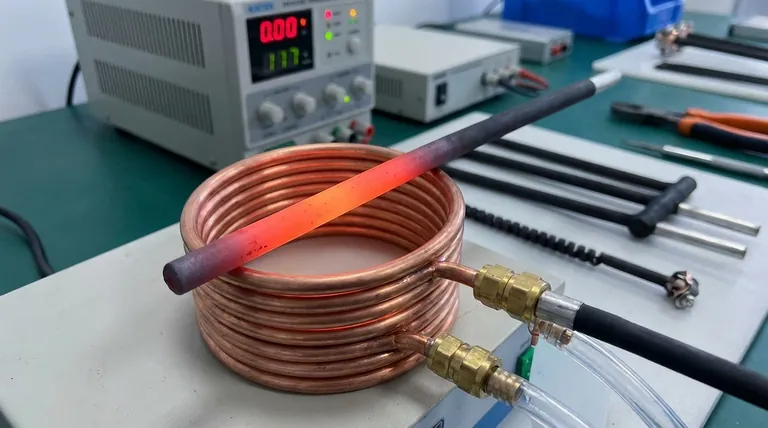

This high-frequency current is sent to the induction coil (or inductor), which is typically made of copper tubing.

As the AC flows through the coil, it generates a powerful and rapidly alternating magnetic field in the space around and within the coil. The design and shape of this coil are crucial for efficient heating.

The Workpiece (The Target)

The workpiece is the object to be heated. The most important requirement is that it must be electrically conductive.

Materials like metals (iron, steel, copper, aluminum) are excellent candidates. The alternating magnetic field from the coil induces small, circular electrical currents within these materials, known as eddy currents.

The Underlying Physics: How It All Works

Understanding the requirements means understanding the principles that make them necessary. The process is a direct application of electromagnetism.

Creating the Magnetic Field

The induction coil acts like an antenna, but instead of broadcasting radio waves, it projects a concentrated magnetic field that constantly and rapidly changes its polarity.

Inducing Eddy Currents

According to Faraday's Law of Induction, this changing magnetic field induces an electrical voltage, and therefore a current, in any conductor placed within it. These are the eddy currents.

Generating Heat via Resistance

As these eddy currents swirl through the workpiece, they encounter the material's natural electrical resistance. This opposition to the current flow generates intense heat, a phenomenon known as Joule heating.

This is why heat is generated inside the object itself, allowing for extremely fast and efficient temperature increases without any physical contact from a heat source.

Critical Limitations and Considerations

While powerful, induction heating is not a universal solution. Its requirements create inherent limitations you must understand.

Material Compatibility is Non-Negotiable

The primary requirement is electrical conductivity. Non-conductive materials like glass, most ceramics, and plastics cannot be heated directly by induction. They do not allow eddy currents to form.

The "Skin Effect" Dictates Heat Location

The induced eddy currents do not flow uniformly through the workpiece. They tend to concentrate near the surface, a principle called the skin effect.

Higher frequencies result in shallower heating, which is ideal for surface hardening. Lower frequencies penetrate more deeply, which is better for melting or forging applications.

Coil Design and Coupling are Key

The efficiency of the energy transfer depends heavily on how closely the coil is "coupled" to the workpiece. The distance and geometric relationship between the coil and the part are critical. A poorly designed or positioned coil will waste significant energy.

Matching the Requirements to Your Goal

The right setup depends entirely on your objective.

- If your primary focus is surface hardening or case hardening: You need a high-frequency power supply to confine the heat to the outer layer of a metal part.

- If your primary focus is melting, forging, or through-heating a large part: A lower-frequency system is required to ensure the magnetic field and heat penetrate deep into the material's core.

- If your primary focus is bonding or curing with a non-conductive material: Induction is only viable if you use a conductive intermediary, like a metal susceptor, which gets hot and transfers its heat via conduction.

By understanding these core requirements, you can effectively determine if induction is the right technology for your application and how to configure it for precise, rapid, and clean results.

Summary Table:

| Component | Role & Key Requirement |

|---|---|

| Power Supply | Generates high-frequency AC current. Frequency controls heat penetration depth. |

| Induction Coil | Creates a rapidly alternating magnetic field. Design is critical for efficiency. |

| Workpiece | Must be electrically conductive (e.g., steel, copper). Heat is generated internally via eddy currents. |

Ready to harness the power of induction heating for your application?

Whether you need a system for surface hardening, melting, or precise thermal processing, KINTEK's expertise in lab equipment ensures you get the right solution. Our team can help you select and configure the ideal induction heating system for your conductive materials, delivering the rapid, clean, and efficient heat you require.

Contact KINTEL today for a consultation and let us help you achieve superior results.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Lab-Scale Vacuum Induction Melting Furnace

- Double Plate Heating Press Mold for Lab

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes