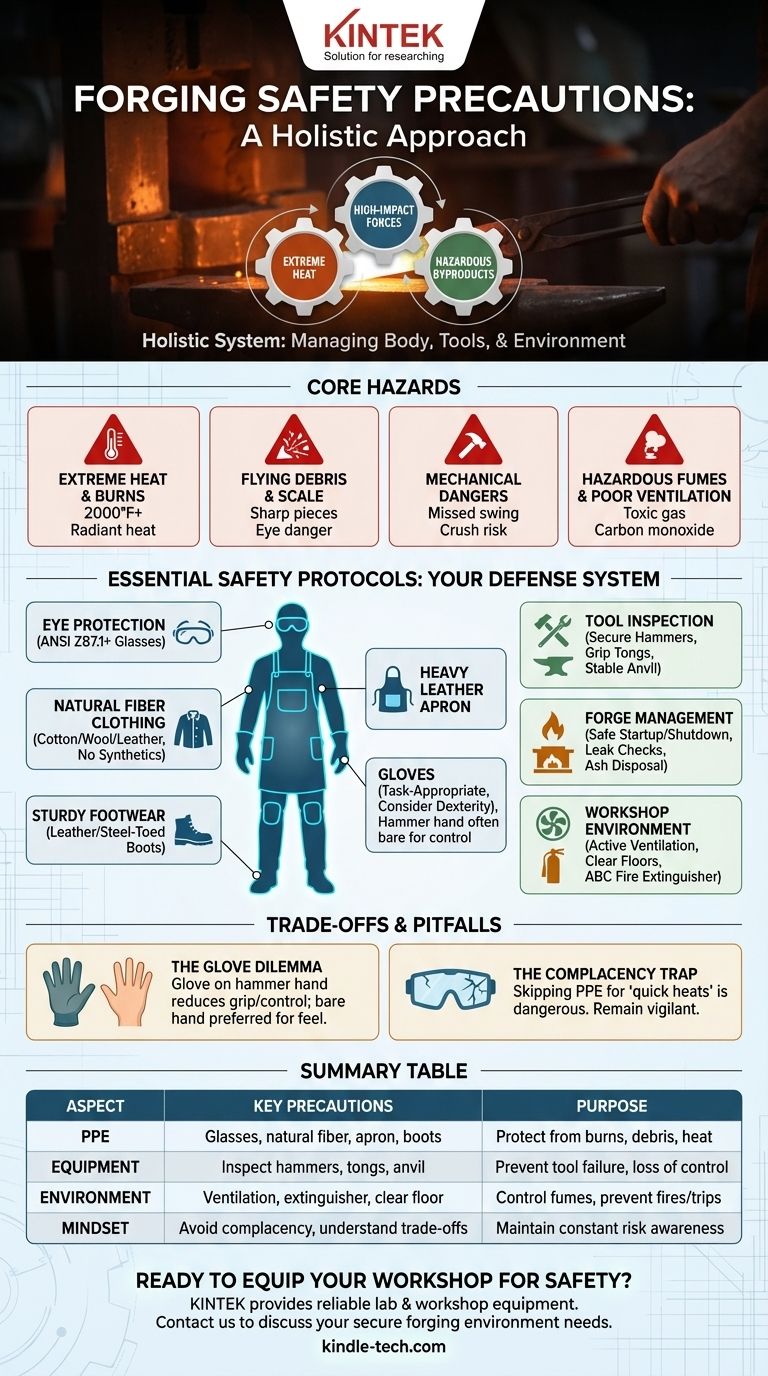

In short, forging safety is a system of interlocking precautions designed to manage extreme heat, high-impact forces, and hazardous byproducts. It requires wearing specific Personal Protective Equipment (PPE) like safety glasses and natural fiber clothing, maintaining equipment meticulously, and ensuring the workshop environment has proper ventilation and fire suppression. These are not optional steps; they are fundamental to preventing severe burns, eye injuries, and other serious harm.

Forging safety is not about a single piece of gear, but a holistic approach. It is the conscious management of your body, your tools, and your environment to control the inherent risks of fire, metal, and force.

The Core Hazards of Forging

To implement effective safety measures, you must first understand the specific dangers you are controlling. Each precaution is a direct response to a significant risk.

Extreme Heat and Burns

The most obvious hazard is the heat from the forge, which can exceed 2,000°F (1,100°C). The workpiece itself becomes a source of intense radiant heat and can cause severe contact burns instantly.

Accidental contact with the forge or hot metal is a primary cause of injury. Even proximity without contact can lead to heat exhaustion.

Flying Debris and Hot Scale

When you strike hot steel, a brittle layer of iron oxide called scale shatters and flies off at high velocity. These small, sharp pieces are extremely hot and can easily embed in your skin or, most dangerously, your eyes.

Similarly, missed hammer blows or metal fracturing under stress can send larger, more dangerous projectiles across the workshop.

Mechanical Dangers

Forging involves significant force, whether from a hand hammer, a power hammer, or a hydraulic press. A missed swing can strike your own body, and power equipment introduces risks of crushing injuries.

Poorly maintained tools, like a hammer with a loose head, can fail catastrophically during use.

Hazardous Fumes and Poor Ventilation

Heating metal, especially if it's galvanized (zinc-coated) or contains other alloys, can release toxic fumes. Even the combustion of fuels like coal or propane produces carbon monoxide, an odorless and deadly gas.

Without adequate ventilation, these fumes can accumulate to dangerous levels, causing short-term illness or long-term respiratory damage.

Essential Safety Protocols: Your System of Defense

Your safety strategy is a multi-layered system. Each layer works together to protect you from the hazards inherent in forging.

Personal Protective Equipment (PPE): Your First Line of Defense

PPE is non-negotiable. It is your personal armor against the immediate environment of the forge.

- Eye Protection: Always wear ANSI Z87.1+ rated safety glasses or goggles. This protects you from high-velocity impact from flying scale and debris.

- Clothing: Wear non-synthetic, natural-fiber clothing like cotton, wool, or leather. Synthetic fabrics (polyester, nylon) will melt onto your skin if they contact hot metal, causing horrific burns.

- Footwear: Sturdy, closed-toe leather or steel-toed boots are essential. They protect your feet from dropped tools, hot metal, and sparks.

- Apron: A heavy leather apron provides an excellent barrier against both radiant heat and direct contact with hot scale or metal.

- Gloves: Use gloves appropriate for the task. Heavy welding gloves can be used for handling material in the fire, but they often reduce dexterity for hammering. Many smiths hammer without a glove on their hammer hand for better control.

Equipment and Tool Inspection

Faulty equipment is a primary source of unexpected accidents. Before every forging session, conduct a brief but thorough inspection.

Check that hammer heads are secured tightly to their handles. Ensure your tongs have a firm grip on the stock. Verify that your anvil is stable and has no major cracks that could fail under impact.

Forge and Fuel Management

Understand how to operate your specific forge safely. This includes proper startup, shutdown, and emergency procedures.

Keep flammable materials far away from the forge area. If using propane, regularly check hoses and connections for leaks with soapy water. For solid fuel forges, have a designated metal container for hot ash disposal.

Workshop Environment and Housekeeping

A clean and organized shop is a safe shop. Keep floors clear of clutter, tools, and steel cut-offs to prevent trips and falls, which are especially dangerous when carrying hot metal.

Ensure you have at least one ABC-rated fire extinguisher easily accessible. A bucket of water or sand is also critical for extinguishing small fires or cooling dropped workpieces.

Understanding the Trade-offs and Common Pitfalls

True safety comes from understanding not just the rules, but the reasons behind them and the common points of failure.

The Glove Dilemma

Wearing heavy gloves on your hammer hand can seem safer, but it often isn't. Bulky gloves reduce your grip and feel, increasing the chance of the hammer twisting in your hand and causing a poorly controlled, dangerous strike.

Many experienced smiths opt for a glove only on their tong hand, leaving the hammer hand bare for maximum control.

The Complacency Trap

After you've been forging for a while, it's easy to become complacent. You might skip putting on your safety glasses for a "quick heat" or wear a synthetic shirt because it's convenient.

This is the most dangerous mindset. Accidents happen in an instant, and they often happen to experienced people who let their guard down. Treat every session with the same respect for the risks.

Misunderstanding Ventilation

Simply opening a garage door may not be enough. Proper ventilation requires active air exchange. You need a system that pulls contaminated air out (like a fume hood) and brings fresh air in. This is especially critical for fuel-burning forges.

Making the Right Choice for Your Goal

Your specific safety focus may shift slightly depending on your work, but the fundamentals never change.

- If your primary focus is hobbyist blacksmithing: Master the PPE fundamentals first. Wearing safety glasses, natural fiber clothing, and keeping a clean workspace with a fire extinguisher will prevent over 90% of common injuries.

- If your primary focus is operating power hammers or presses: Your attention must expand to machine guarding, emergency stop controls, and developing a rhythm that keeps your hands clear of pinch points at all times.

- If your primary focus is managing a professional shop: Implement a formal, written safety program. This includes regular training, documented equipment inspections, and investing in engineered solutions like robust ventilation and fume extraction systems.

Ultimately, safety is not a barrier to your work; it is the foundation that enables you to practice the craft with confidence and longevity.

Summary Table:

| Aspect of Safety | Key Precautions | Purpose |

|---|---|---|

| Personal Protective Equipment (PPE) | Safety glasses, natural fiber clothing, leather apron, sturdy boots | Protect from burns, flying debris, and radiant heat |

| Equipment & Tools | Pre-use inspection of hammers, tongs, and anvil stability | Prevent catastrophic tool failure and loss of control |

| Workshop Environment | Active ventilation, ABC fire extinguisher, clear floor space | Control toxic fumes, prevent fires, and avoid trips/falls |

| Mindset & Practice | Avoid complacency, understand trade-offs (e.g., glove use) | Maintain constant awareness of inherent risks |

Ready to Equip Your Workshop for Maximum Safety?

KINTEK specializes in providing reliable lab and workshop equipment designed with safety and performance in mind. Whether you're a hobbyist blacksmith or managing a professional metalworking facility, having the right tools is the first step in building a safe practice.

Contact us today to discuss your needs. Our experts can help you select the right equipment to create a secure and efficient forging environment, protecting you from heat, force, and fumes.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- Why are industrial homogenizers required for composite photosensitive resins? Ensure Uniform Particle Dispersion

- What is the role of the constant flow and constant pressure pump in core flooding? Master Deep Granite Stimulation

- Which chemical is used in heat treatment? Master Quenching and Case Hardening for Superior Metals

- What is the most common error associated with a melting point determination? Avoid Heating Too Fast for Accurate Results

- What are the basics of heat treating? Master Temperature, Time, and Cooling for Superior Metal Properties

- What is sinter temperature? Master the Key to Perfect Powder Metallurgy

- How does evaporation occur in Ultra Freezers? The Core Process for Deep Freezing

- What is fusion in XRF? Achieve Unmatched Accuracy in Elemental Analysis