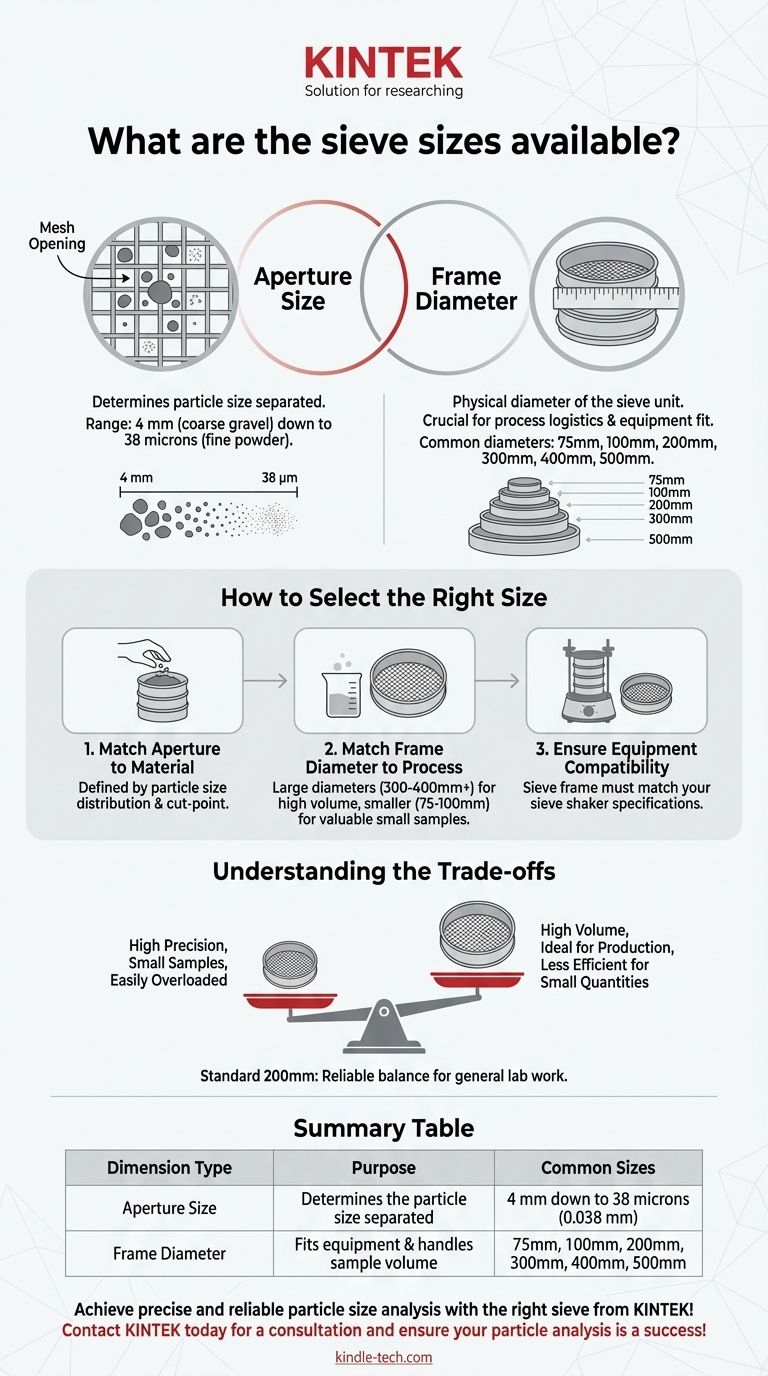

To be precise, the term "sieve size" refers to two distinct measurements which are often used interchangeably. The aperture size of the mesh, which dictates the particle size being separated, commonly ranges from 4 millimeters down to as fine as 38 microns. The physical frame diameter of the sieve itself is also a critical size, with standard options including 75mm, 100mm, 200mm, 300mm, and 400mm.

When selecting a sieve, you must consider both the aperture size to properly separate your material and the frame diameter to ensure it fits your equipment and is appropriate for your sample volume. Confusing the two is a common source of error.

The Two Critical Sieve Dimensions

To make an informed choice, it is essential to understand the function of each measurement. Both are critical for achieving accurate and repeatable results in particle size analysis.

Aperture Size (Mesh Size)

The aperture size is the actual dimension of the openings in the sieve mesh. This is the single most important factor for particle separation.

This measurement dictates the largest particle that can pass through the sieve. The available range, from 4 mm down to 38 microns (0.038 mm), covers applications from coarse gravel to fine powders.

Frame Diameter

The frame diameter is the physical diameter of the sieve unit itself. This dimension does not affect the size of the particles separated but is crucial for process logistics.

Common diameters for laboratory and light industrial use are 75mm, 100mm, 200mm, 300mm, 400mm, and 500mm. The diameter you choose is determined by sample volume and equipment compatibility.

How to Select the Right Size for Your Application

Your choice depends entirely on your material, your goals, and your equipment. The right selection balances precision with practicality.

Matching Aperture to Your Material

Your required aperture size is defined by the particle size distribution of your sample and the cut-point you need to measure.

A series of sieves with progressively smaller apertures, known as a sieve stack, is used to determine the particle size distribution of a given material.

Matching Frame Diameter to Your Process

The frame diameter must be large enough to handle your sample volume without "blinding" the sieve, which occurs when the mesh becomes clogged.

Larger diameters (e.g., 300mm, 400mm) are suited for larger sample volumes, while smaller diameters (e.g., 75mm, 100mm) are used for smaller, often more valuable, samples.

Ensuring Equipment Compatibility

Your sieve's frame diameter must match your sieve shaker. A 200mm diameter sieve will not fit in a shaker designed for 300mm sieves. Always verify the specifications of your shaker before purchasing new sieves.

Understanding the Trade-offs

Choosing a sieve size involves balancing competing factors. There is no single "best" size, only the most appropriate size for a specific task.

Precision vs. Volume

Smaller diameter sieves can offer high precision for small samples but are easily overloaded.

Larger diameter sieves can process significantly more material, making them ideal for production environments, but they can be less efficient for separating very small sample quantities.

Cost and Footprint

Unsurprisingly, larger diameter sieves and the corresponding sieve shakers are more expensive and occupy more laboratory or floor space.

A standard 200mm diameter sieve is often the most common choice for general laboratory work, as it provides a reliable balance between sample capacity, accuracy, and cost.

Making the Right Choice for Your Goal

Use your primary objective to guide your selection.

- If your primary focus is high-volume material processing: You will need larger frame diameters (300mm, 400mm, or more) to handle the material load efficiently.

- If your primary focus is precise laboratory analysis: Standard 200mm sieves offer an excellent balance, while 75mm or 100mm sieves are ideal for very small samples.

- If you are purchasing for existing equipment: Your first step must be to confirm the required frame diameter to ensure complete compatibility with your sieve shaker.

Selecting the correct sieve dimensions is the foundational step for achieving reliable and repeatable particle size analysis.

Summary Table:

| Dimension Type | Purpose | Common Sizes |

|---|---|---|

| Aperture Size | Determines the particle size separated | 4 mm down to 38 microns (0.038 mm) |

| Frame Diameter | Fits equipment & handles sample volume | 75mm, 100mm, 200mm, 300mm, 400mm, 500mm |

Achieve precise and reliable particle size analysis with the right sieve from KINTEK!

Selecting the correct sieve is critical for your lab's accuracy and efficiency. KINTEK specializes in high-quality lab equipment and consumables, offering a comprehensive range of sieves to meet your specific application needs—whether for high-volume processing or precise laboratory analysis.

Let our experts help you choose the perfect sieve size for your material and equipment. Contact KINTEK today for a consultation and ensure your particle analysis is a success!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What are the advantages and disadvantages of sieve analysis? A Guide to Cost-Effective Particle Sizing

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture