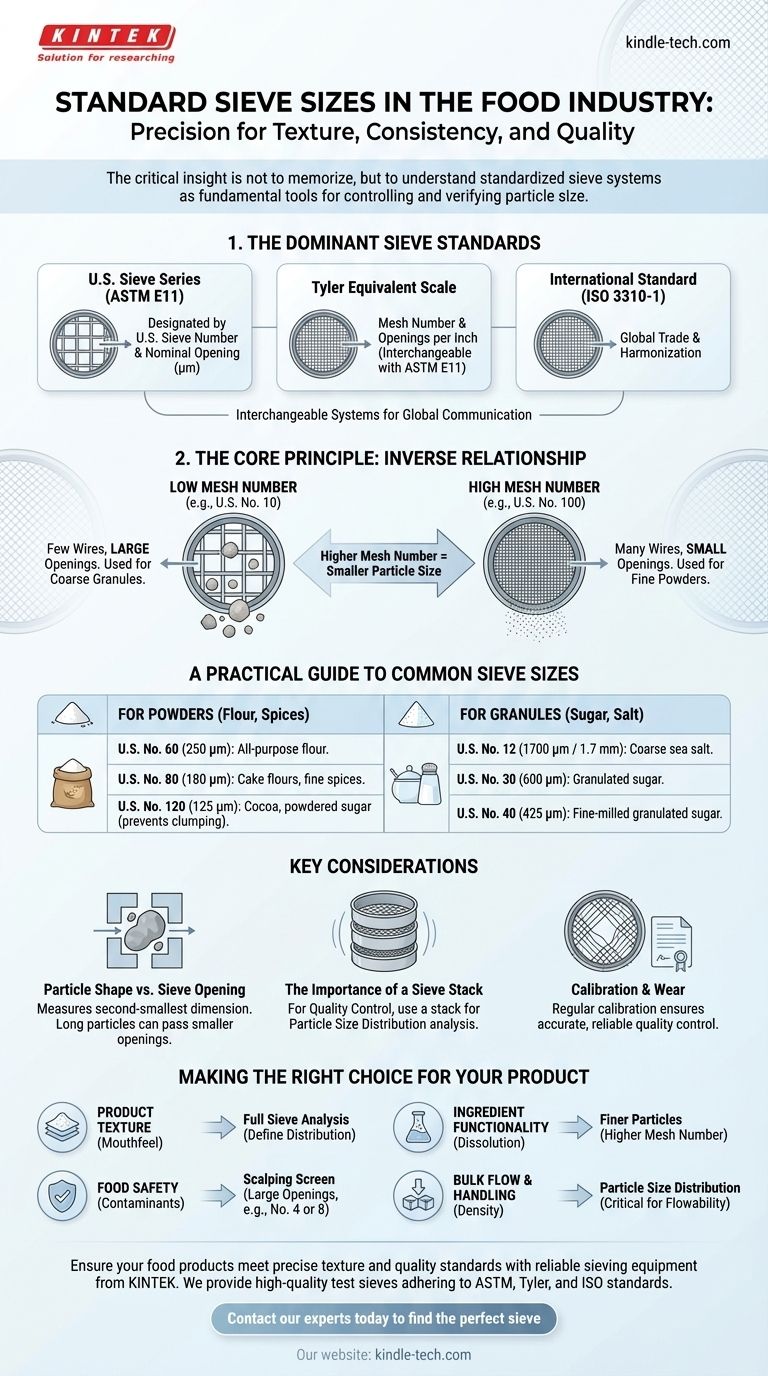

In the food industry, standard sieve sizes are defined by internationally recognized systems, most notably the U.S. Sieve Series (ASTM E11) and the nearly identical Tyler Equivalent Scale. These standards provide a common language for specifying the particle size of ingredients like flour, sugar, and spices, linking a "mesh number" (wires per inch) to a precise opening size measured in micrometers (µm) or millimeters (mm).

The critical insight is not to memorize a single list of sizes, but to understand that these standardized sieve systems are the fundamental tools for defining, controlling, and verifying particle size, which directly dictates a food product's final texture, consistency, and performance.

The Dominant Sieve Standards Explained

To control product quality, the industry relies on a few key, interchangeable standards. They provide the framework for communication between suppliers, processors, and quality assurance teams.

The U.S. Sieve Series (ASTM E11)

This is the current, predominant standard in the United States and is widely used globally. It designates sieves by a U.S. Sieve Number, which approximates the number of wire openings per linear inch.

The critical measurement, however, is the nominal sieve opening in micrometers (µm). Each successive sieve in the series has an opening size that is the previous size divided by the fourth root of 2 (approximately 1.189).

The Tyler Equivalent Scale

This is an older but still commonly referenced system. Its "mesh" designation is also based on the number of openings per inch.

For most practical purposes, the Tyler and U.S. Sieve series are nearly interchangeable. For example, a 35 mesh Tyler screen is equivalent to a U.S. No. 35 sieve, both having a 500 µm opening.

International Standard (ISO 3310-1)

For global trade and harmonization, the ISO standard is the key reference. It is very similar to the ASTM E11 standard, ensuring that specifications can be understood and met across international markets.

A Practical Guide to Common Sieve Sizes

Understanding the relationship between the mesh number and the opening size is essential for applying these standards effectively.

The Core Principle: Inverse Relationship

The most important concept to remember is the inverse relationship between the mesh number and the particle size it will pass.

- High Mesh Number (e.g., U.S. No. 100) = Many wires, small openings. Used for fine powders like confectioner's sugar.

- Low Mesh Number (e.g., U.S. No. 10) = Few wires, large openings. Used for coarse granules like rock salt.

Common Sizes for Powders (Flour, Spices)

Fine powders require sieves with high mesh numbers to ensure a smooth, uniform texture.

- U.S. No. 60 (250 µm): A common specification for all-purpose flour.

- U.S. No. 80 (180 µm): Often used for finer cake flours or certain spices.

- U.S. No. 120 (125 µm): Used for very fine powders like cocoa or powdered sugar to prevent clumping.

Common Sizes for Granules (Sugar, Salt)

Granular products are defined by particles large enough to be perceived individually.

- U.S. No. 12 (1700 µm or 1.7 mm): A typical size for coarse sea salt.

- U.S. No. 30 (600 µm): A standard size for granulated sugar.

- U.S. No. 40 (425 µm): Often used to define fine-milled granulated sugar.

Understanding the Key Considerations

Using sieves effectively goes beyond simply picking a number. It involves understanding the limitations of the method and the goal of the analysis.

Particle Shape vs. Sieve Opening

Sieving assumes a spherical particle. However, most food particles are irregular. A sieve measures the second-smallest dimension of a particle—the one that allows it to pass through the square opening.

This means long, needle-shaped particles can pass through a sieve that is much smaller than their total length, which can be misleading if not accounted for.

The Importance of a Sieve Stack

For true quality control, a single sieve is insufficient. Processors use a stack of sieves with progressively smaller openings, from top to bottom.

Shaking this stack separates the material into different size fractions. This process, known as a sieve analysis, reveals the product's particle size distribution, not just a simple pass/fail. This distribution is the true fingerprint of a product's texture.

Calibration and Wear

Test sieves are precision instruments. Over time, the wires can stretch or break, and the openings can become distorted, leading to inaccurate results.

Regular inspection and calibration against a known standard are critical manufacturing practices to ensure that quality control measurements remain valid and reliable.

Making the Right Choice for Your Product

The correct sieve size is always determined by the desired outcome for the final food product.

- If your primary focus is product texture: You need a full sieve analysis to define the acceptable particle size distribution for the desired mouthfeel, from gritty to smooth.

- If your primary focus is ingredient functionality: Use finer particles (a higher mesh number) to increase surface area for faster dissolution, such as in drink mixes.

- If your primary focus is food safety: Employ a large-opening "scalping" screen (e.g., U.S. No. 4 or 8) at the start of the process to remove clumps and foreign contaminants.

- If your primary focus is bulk flow and handling: The particle size distribution will directly impact the bulk density and flowability of powders, which is critical for preventing clogging in machinery.

Ultimately, mastering sieve standards is about precisely controlling particle size to guarantee your product's quality, safety, and consistency with every batch.

Summary Table:

| Common Sieve Size (U.S. No.) | Opening Size (µm) | Typical Food Application |

|---|---|---|

| No. 12 | 1700 µm | Coarse sea salt |

| No. 30 | 600 µm | Granulated sugar |

| No. 40 | 425 µm | Fine-milled granulated sugar |

| No. 60 | 250 µm | All-purpose flour |

| No. 80 | 180 µm | Cake flour, fine spices |

| No. 120 | 125 µm | Powdered sugar, cocoa |

Ensure your food products meet precise texture and quality standards with reliable sieving equipment from KINTEK.

As a leading supplier of laboratory equipment and consumables, KINTEK provides high-quality test sieves that adhere to ASTM, Tyler, and ISO standards. Whether you are analyzing flour, sugar, spices, or other ingredients, our sieves deliver the accuracy and durability needed for consistent batch-to-batch results.

Contact our experts today to find the perfect sieve for your application and enhance your quality control process.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation