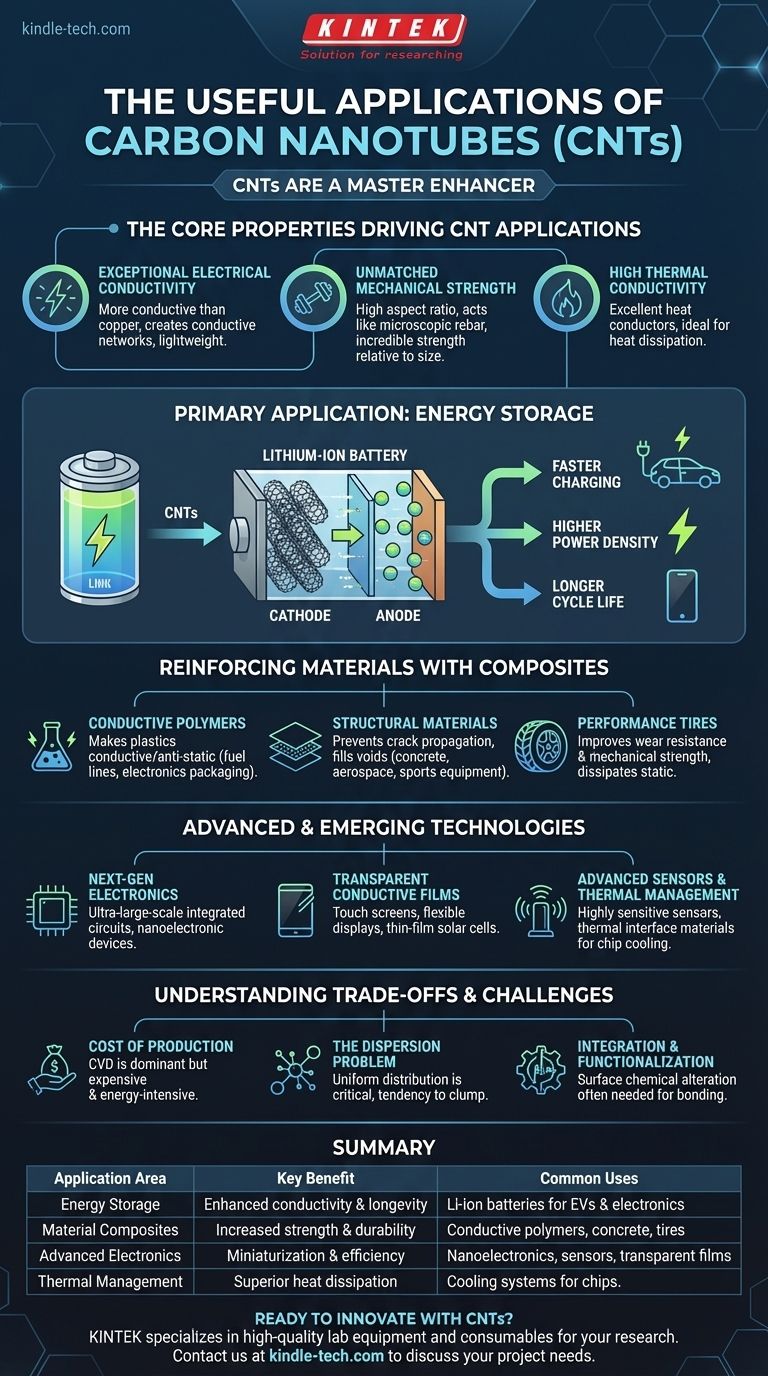

The most useful and commercially significant application of carbon nanotubes is as a high-performance conductive additive in the electrodes of lithium-ion batteries. Their exceptional electrical conductivity and high aspect ratio improve battery performance and longevity. Beyond this, they are increasingly used to create advanced composites, reinforcing materials like polymers and concrete, and are foundational to emerging electronic and sensor technologies.

The true value of carbon nanotubes lies not in a single, standalone product, but in their role as a master enhancer. By integrating them into existing materials, we unlock significant improvements in electrical conductivity, mechanical strength, and thermal performance with minimal added weight.

The Core Properties Driving CNT Applications

To understand the applications of carbon nanotubes (CNTs), you must first understand the three fundamental properties that make them so valuable. These unique characteristics are the reason they are being integrated into so many different fields.

Exceptional Electrical Conductivity

CNTs can be more conductive than copper, but at a fraction of the weight. This allows them to create electrically conductive networks within otherwise non-conductive materials, such as plastics or polymers.

Unmatched Mechanical Strength

Relative to their size, CNTs are one of the strongest materials ever discovered. Their high aspect ratio (very long and thin) allows them to act like rebar on a microscopic scale, effectively reinforcing the structure of a host material.

High Thermal Conductivity

Carbon nanotubes are also excellent conductors of heat. This property makes them ideal for applications where efficiently dissipating heat is critical, such as in electronics and advanced materials.

Primary Application Area: Energy Storage

The most mature and widespread use of CNTs today is in improving the batteries that power everything from electric vehicles to consumer electronics.

Enhancing Lithium-Ion Batteries

CNTs are added to both the cathode and anode of lithium-ion batteries. Their conductive network allows for faster charging and discharging by improving electron transport. This leads to higher power density, longer cycle life, and better overall battery efficiency.

Reinforcing Materials with Composites

The second major application category involves mixing small amounts of CNTs into a bulk material (a "matrix") to form a composite with superior properties.

Creating Conductive Polymers

Standard polymers and plastics are electrical insulators. Adding CNTs makes them conductive or anti-static, which is critical for applications like fuel lines, electronics packaging, and automotive components where static discharge must be prevented.

Strengthening Structural Materials

When added to materials like concrete, asphalt, or fiber-reinforced polymers (used in aerospace and high-performance sports equipment), CNTs fill microscopic voids and prevent the propagation of cracks. This results in a final material that is significantly stronger, more durable, and more resistant to wear.

Improving Performance Tires

In the tire industry, CNTs are used as an additive to rubber composites. They improve the mechanical strength and wear resistance of the tire while also helping to dissipate static electricity generated by the moving vehicle.

Advanced and Emerging Technologies

While not yet as widespread as battery and composite applications, CNTs are enabling a new generation of high-performance technologies.

Next-Generation Electronics

Due to their tiny size and excellent conductivity, CNTs are being used to develop ultra-large-scale integrated circuits, pushing past the limits of traditional silicon. They are a key component in creating smaller, faster, and more efficient nanoelectronic devices.

Transparent Conductive Films

CNTs can be deposited on glass or flexible substrates to create films that are both electrically conductive and transparent. This makes them a potential replacement for existing materials in touch screens, flexible displays, and thin-film solar cells.

Advanced Sensors and Thermal Management

The high surface area and conductivity of CNTs make them extremely sensitive to their chemical environment, which is ideal for creating highly accurate sensors. In parallel, their ability to dissipate heat is leveraged in thermal interface materials to cool high-performance computer chips.

Understanding the Trade-offs and Challenges

Despite their remarkable potential, the widespread adoption of CNTs is constrained by several key factors that must be considered.

Cost of Production

While chemical vapor deposition (CVD) has become the dominant commercial process, producing high-quality CNTs remains a relatively expensive and energy-intensive endeavor compared to traditional materials.

The Dispersion Problem

For CNTs to be effective, they must be distributed evenly throughout the host material. However, they naturally tend to clump together, which is a major technical hurdle. Achieving uniform dispersion is critical to unlocking their benefits.

Integration and Functionalization

Simply mixing CNTs into a material is often not enough. To ensure they bond properly with the host matrix, their surface often needs to be chemically altered, a process known as functionalization, which adds cost and complexity.

Making the Right Choice for Your Goal

The relevance of carbon nanotubes depends entirely on the objective. Their application is not monolithic; it is highly specific to the problem you are trying to solve.

- If your primary focus is immediate commercial impact: The most mature and valuable application is as a conductive additive in lithium-ion batteries and conductive polymers.

- If your primary focus is long-term structural improvement: Concentrate on their use in advanced composites for the aerospace, automotive, and construction industries.

- If your primary focus is next-generation technology: Explore their foundational role in nanoelectronics, transparent films, and highly sensitive sensors.

Ultimately, carbon nanotubes are best understood as a master-enhancer, poised to make the materials we already depend on stronger, lighter, and more efficient.

Summary Table:

| Application Area | Key Benefit | Common Uses |

|---|---|---|

| Energy Storage | Enhanced conductivity & longevity | Lithium-ion batteries for EVs & electronics |

| Material Composites | Increased strength & durability | Conductive polymers, concrete, tires |

| Advanced Electronics | Miniaturization & efficiency | Nanoelectronics, sensors, transparent films |

| Thermal Management | Superior heat dissipation | Cooling systems for high-performance chips |

Ready to leverage carbon nanotubes for your projects?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your research and production needs. Whether you're developing advanced batteries, stronger composites, or cutting-edge electronics, our expertise ensures you get the right tools to innovate with confidence.

Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Three-dimensional electromagnetic sieving instrument

- Graphite Vacuum Continuous Graphitization Furnace

- Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

- Aluminum Foil Current Collector for Lithium Battery

People Also Ask

- What is a sputtering target? The Blueprint for High-Performance Thin-Film Coatings

- What are thin films? Unlock Advanced Material Performance with High-Precision Surface Coatings

- What is the difference between carbon nanotubes and graphene oxide? Choose the Right Nanomaterial for Your Application

- How thick is diamond coating? Achieve Unprecedented Precision with Ultra-Thin Films

- What are the advantages and applications of electronic thin films? Precision Engineering for High-Efficiency Design

- What is the meaning of synthesis of graphene? A Guide to Top-Down vs. Bottom-Up Methods

- What is the alternative material for graphene? Discover the Top 2D Materials for Your Specific Application

- What is sputtering in deposition technique? Achieve Precise, High-Quality Thin Films