To directly control arc length in arc heating, you must primarily adjust the system's operating voltage and the physical distance between the electrodes. Increasing the voltage allows the electric arc to be sustained across a greater distance, while physically moving the electrodes farther apart forces the arc to lengthen, provided the power supply can support it. The composition and pressure of the gas or slag in the arc zone also play a critical, albeit less direct, role in determining the final length.

Arc length is not a simple setting, but an outcome. It represents the dynamic equilibrium between the electrical power you supply and the physical and chemical environment the arc exists within. True control comes from understanding how these factors interact to influence not just length, but overall heating performance.

The Core Principles of Arc Length Control

To effectively manage arc heating, you must understand the fundamental forces that dictate the arc's behavior. These are not independent knobs to turn, but interconnected variables.

The Role of Voltage

The voltage supplied by the power system determines the electrical potential between the electrodes. Think of this as the "pressure" pushing the electricity across the gap.

A higher voltage provides more potential energy, enabling the arc to jump and sustain itself across a longer distance. A lower voltage can only sustain a shorter arc.

The Physical Electrode Gap

In applications like electric arc furnaces (EAF), the electrodes are mounted on mechanical arms. Physically raising or lowering these electrodes is the most common method of controlling the arc.

When you increase the gap, the system's automatic regulator will attempt to increase the voltage to maintain a stable arc, thereby lengthening it. Conversely, decreasing the gap allows for a shorter, lower-voltage arc.

The Influence of Arc Current

While voltage primarily dictates the potential length, current dictates the arc's robustness. A higher current creates a larger, more powerful plasma column.

This thicker, higher-amperage arc is generally more stable and can be sustained more easily, especially when it is long. A low-current arc is "thinner" and more susceptible to being extinguished, especially over longer distances.

The Impact of the Atmosphere

The arc does not exist in a vacuum. The gas, slag, and metal vapors in the gap have a profound effect on its properties.

A key factor is ionization potential. Gases like argon ionize easily, allowing for a stable arc at a lower voltage. Air (specifically nitrogen) is harder to ionize and requires more voltage. In a furnace, a layer of foamy slag can dramatically change the arc's environment, enabling a stable, long arc while shielding the furnace walls.

Why Arc Length Matters: The Practical Consequences

The reason we control arc length is that it directly impacts the efficiency, stability, and cost of the entire heating process.

Heat Transfer Efficiency

A long arc transfers a significant portion of its energy via radiation. This radiates heat in all directions, including to the furnace roof and walls (refractory).

A short arc transfers more of its energy directly into the material below it (the molten bath or scrap pile) through conduction and convection. This is a much more focused and efficient form of heating.

Arc Stability and Flicker

Long arcs tend to be less stable. They can wander, deflect (a phenomenon known as "arc blow"), and even extinguish and re-ignite rapidly.

This instability causes rapid fluctuations in power draw, leading to voltage flicker on the electrical grid. This can disrupt other equipment and lead to penalties from the utility provider. Short arcs are inherently more stable.

Refractory Wear

The radiative heat from a long arc is extremely damaging to the furnace's heat-resistant refractory lining. This significantly increases maintenance costs and furnace downtime.

A short, focused arc that is "buried" in the charge or slag directs its energy downwards, protecting the furnace walls and roof.

Understanding the Trade-offs

Choosing an arc length is always a compromise based on the specific goal at that moment in the process.

Long Arc: High Radiation, High Risk

A long, radiative arc is excellent for the initial "bore-in" and meltdown phase of a scrap charge. It radiates heat over a wide surface area, melting a large volume of material quickly.

However, it is inefficient in terms of energy consumption (kWh/ton) and causes severe refractory wear if not managed carefully with a protective slag cover.

Short Arc: Focused Power, Potential Issues

A short, stable arc is ideal for the refining stage when the scrap is already molten. It delivers energy directly into the liquid bath with maximum efficiency and minimal refractory damage.

The main risk is being "too short." If the slag layer is not right, the arc can become smothered, or the electrode may even make direct contact with the molten bath, causing a disruptive short circuit.

The Critical Role of Slag

Modern arc heating, especially in steelmaking, relies on creating a foamy slag layer. This layer of bubbles allows the operator to use a long, powerful, and radiative arc while the foam itself insulates the furnace walls from that radiation. This technique provides the "best of both worlds": the high power of a long arc with the protection of a short one.

Optimizing Arc Length for Your Goal

The ideal arc length is not a single value but depends entirely on the operational phase and desired outcome. Use these principles to make an informed decision.

- If your primary focus is rapid initial melting of scrap: Use a longer arc to radiate heat over a wide area, but be prepared for higher refractory wear.

- If your primary focus is energy efficiency and final refining: Use a shorter, stable arc that burrows into the molten bath or is shielded by a foamy slag.

- If your primary focus is minimizing refractory costs: Prioritize shorter arcs or the development of a consistent, protective foamy slag practice to shield the furnace walls.

- If your primary focus is reducing grid flicker: Operate with a shorter, more stable arc to minimize power fluctuations.

Ultimately, mastering arc length is about dynamically balancing electrical power with the furnace's physical and chemical conditions to achieve precise and efficient heating.

Summary Table:

| Goal | Recommended Arc Length | Key Control Method | Key Benefit |

|---|---|---|---|

| Rapid Initial Melting | Long Arc | Increase Voltage / Electrode Gap | Wide Radiative Heat |

| Energy Efficiency & Refining | Short Arc | Decrease Voltage / Electrode Gap | Focused Conductive Heat |

| Minimize Refractory Wear | Short Arc or Foamy Slag | Optimize Slag Composition | Protects Furnace Lining |

| Reduce Grid Flicker | Short Arc | Maintain Stable Electrode Gap | Stable Power Draw |

Optimize your arc heating process with precision equipment from KINTEK.

Whether you are running an electric arc furnace for steelmaking or a laboratory-scale arc melter, achieving the perfect balance of arc length, stability, and efficiency is critical. KINTEK specializes in high-performance lab equipment and consumables, providing the robust power supplies, durable electrodes, and expert support you need to master your thermal processes.

Contact our experts today to discuss how our solutions can help you increase melt rates, improve energy efficiency, and extend equipment lifespan.

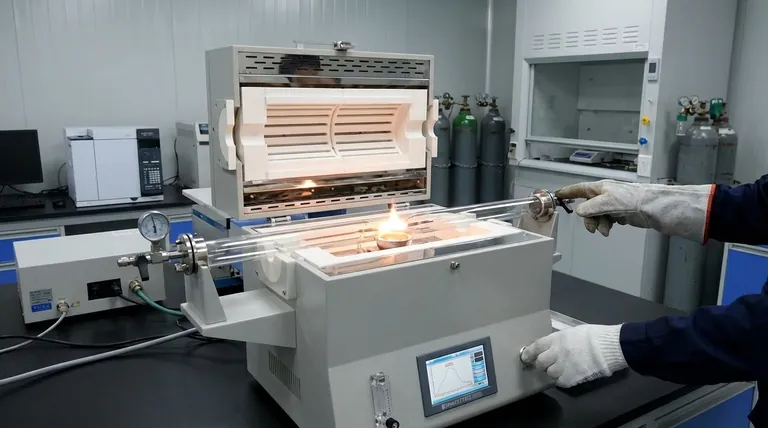

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How is the temperature in a tube furnace measured and controlled? Master Precise Thermal Processing