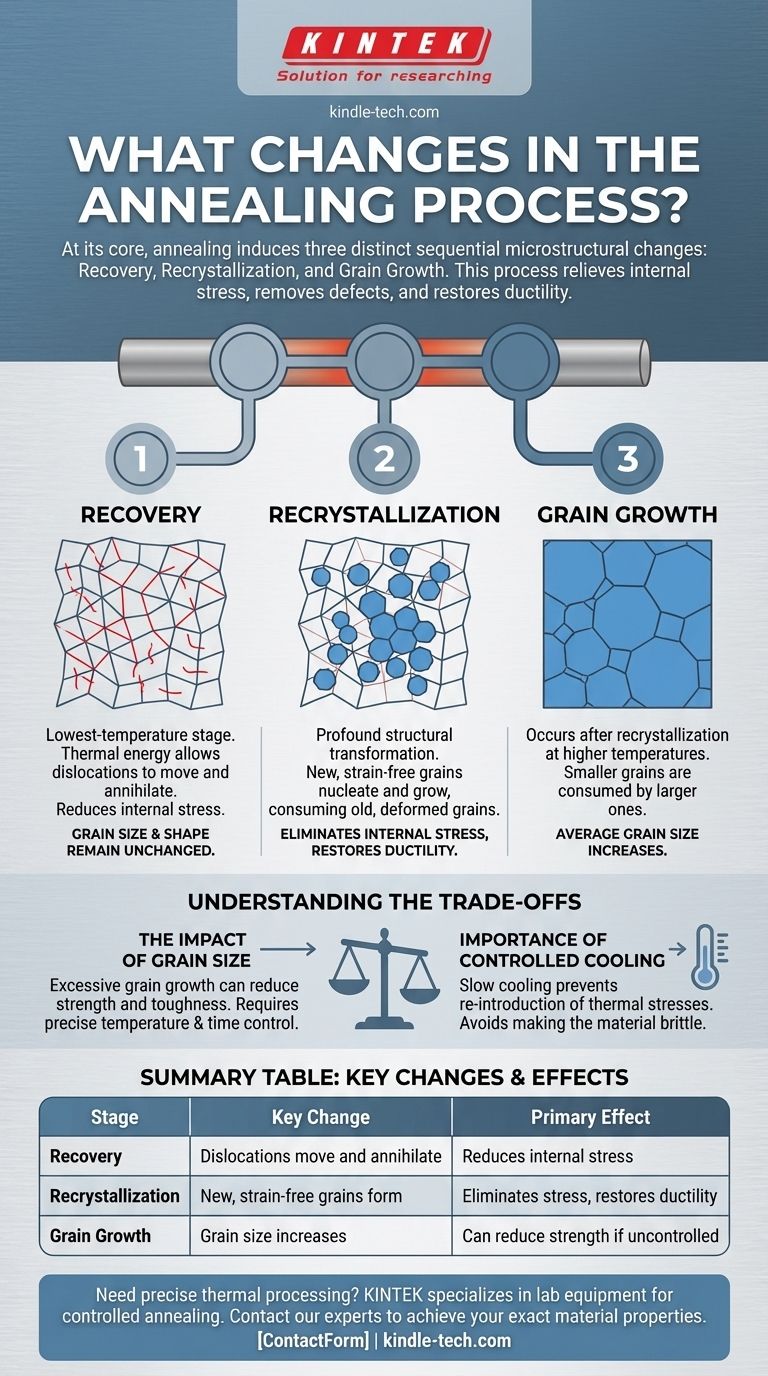

At its core, the annealing process induces three distinct and sequential changes within a metal's internal microstructure. These changes are Recovery, Recrystallization, and Grain Growth, which collectively work to relieve internal stresses, remove defects, and restore the material's ductility.

Annealing is not a single event but a controlled thermal process that systematically repairs a metal's internal crystal structure. By carefully managing temperature and time, you can reverse the effects of work-hardening and fabrication stress, transforming a brittle, stressed material into a more ductile and stable one.

The Purpose: Reversing Internal Damage

Before examining the stages, it's crucial to understand why annealing is necessary. Manufacturing processes like casting, forging, or cold working create internal stress and defects within a metal's crystalline structure.

What is Internal Stress?

During fabrication, the metal's crystal lattice becomes distorted. These imperfections, primarily linear defects known as dislocations, are like microscopic tangles that prevent atoms from sliding past one another easily.

This accumulation of dislocations is what makes a metal harder but also more brittle—a state known as work-hardening.

The Goal: Restoring Ductility and Relieving Stress

The primary purpose of annealing is to relieve these internal stresses and "untangle" the dislocations.

By doing so, the process restores ductility (the ability to deform without fracturing) and makes the material softer and easier to work with for subsequent operations.

The Three Stages of Microstructural Change

The transformation during annealing does not happen all at once. It progresses through three distinct stages as the temperature of the material is increased and held.

Stage 1: Recovery

Recovery is the first and lowest-temperature stage of the process. During this phase, the metal begins to soften as thermal energy allows dislocations to move and annihilate each other.

This rearrangement significantly reduces the material's stored internal stress. Critically, the original grain size and shape do not change during the recovery stage.

Stage 2: Recrystallization

As the temperature continues to rise or is held for a sufficient duration, Recrystallization begins. This is a profound structural transformation.

New, perfectly formed, strain-free crystals (grains) begin to nucleate and grow, consuming and completely replacing the old, deformed grains that were filled with dislocations. At the end of this stage, the internal stress is effectively eliminated.

Stage 3: Grain Growth

If the metal is held at the annealing temperature after recrystallization is complete, Grain Growth occurs.

In this final stage, the smaller of the new, strain-free grains are consumed by their larger neighbors. This causes the average grain size of the material to increase.

Understanding the Trade-offs

While annealing is a powerful tool for improving material properties, it is not without critical considerations. The outcome is highly sensitive to process control.

The Impact of Grain Size

The final grain size has a significant impact on mechanical properties. While a full recrystallization is needed to maximize ductility, excessive grain growth can sometimes reduce the material's overall strength and toughness.

Controlling the final grain size requires precise management of both temperature and the time the material is held at that temperature.

The Importance of Controlled Cooling

The final step—slowly cooling the material back to room temperature—is just as important as the heating.

Cooling the metal too quickly can re-introduce thermal stresses, partially negating the benefits of the process and potentially making the material brittle again. The slow cooling rate allows the repaired crystal structure to settle into a stable, low-stress state.

Applying This to Your Goal

The specific annealing cycle you use should be tailored to your desired material outcome. Use the three stages as a guide to achieve your engineering objective.

- If your primary focus is stress relief without altering strength: Aim for a process that completes the Recovery stage but stops before significant recrystallization occurs.

- If your primary focus is to maximize softness and ductility: You must ensure the process is sufficient to fully complete the Recrystallization stage.

- If your primary focus is achieving a specific balance of strength and ductility: You must precisely control temperature and time to manage the extent of Grain Growth after recrystallization is complete.

By understanding these three distinct stages, you gain precise control over a material's final mechanical properties.

Summary Table:

| Stage | Key Change | Primary Effect |

|---|---|---|

| Recovery | Dislocations move and annihilate | Reduces internal stress |

| Recrystallization | New, strain-free grains form | Eliminates stress, restores ductility |

| Grain Growth | Grain size increases | Can reduce strength if uncontrolled |

Need precise thermal processing for your materials?

KINTEK specializes in the lab equipment and consumables necessary for controlled annealing processes. Whether you are developing new materials or optimizing heat treatment cycles in your laboratory, our solutions help you achieve the exact material properties—from stress relief to ductility—that your research demands.

Contact our experts today to discuss how we can support your lab's specific annealing and heat treatment needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease