Pills are manufactured using a specialized machine known as a tablet press or pill press. This industrial device uses immense, precisely controlled force to compact powdered or granular material into a solid tablet of a uniform size, shape, and weight. It is the cornerstone of tablet production in the pharmaceutical and nutraceutical industries.

The process of creating a tablet isn't just about simple pressing. It's a precise mechanical operation involving dies, punches, and carefully calibrated pressure within a tablet press to ensure each pill has the correct dosage, hardness, and stability.

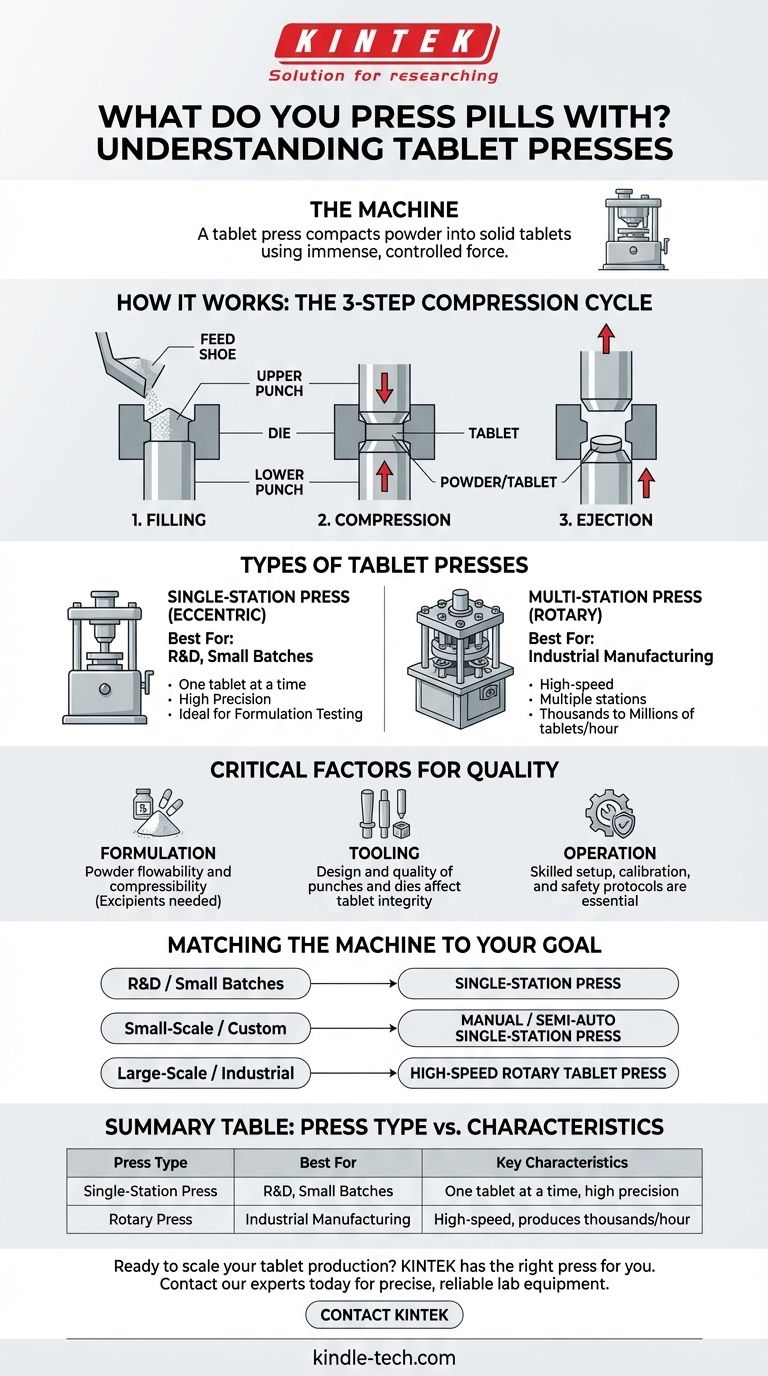

How a Tablet Press Works: The Core Mechanism

Understanding the machine requires looking at its fundamental components and the cycle they perform thousands or even millions of times.

The Key Components: Punches and Dies

The heart of any tablet press consists of three main parts: a die, an upper punch, and a lower punch.

The die is a mold that defines the final shape and diameter of the tablet. The powder or granulation fills this cavity.

The punches are steel tools that move within the die to compress the powder. The lower punch forms the bottom of the die cavity, while the upper punch descends to apply the main compression force.

The Compression Cycle

The creation of a single tablet happens in a rapid, three-step cycle.

- Filling: The lower punch sits low inside the die, creating a cavity that is filled with the powdered formulation.

- Compression: The upper punch lowers into the die, and both the upper and lower punches move together, applying extreme pressure to the powder and compacting it into a solid form.

- Ejection: The upper punch retracts, and the lower punch rises, pushing the finished tablet out of the die cavity.

Types of Tablet Presses for Different Scales

The specific type of press used depends entirely on the required output, from laboratory research to full-scale industrial production.

Single-Station Presses

Also known as eccentric presses, these are the simplest form of tablet press. They feature one die and one set of upper and lower punches.

These machines are typically used for research and development (R&D) or for producing very small batches, as they produce one tablet at a time.

Multi-Station (Rotary) Presses

Rotary presses are the standard for large-scale manufacturing. They feature a rotating turret that holds numerous sets of dies and punches.

As the turret spins, each set of tooling moves through the fill, compression, and ejection stages simultaneously. This continuous motion allows for the production of hundreds of thousands, or even millions, of tablets per hour.

Understanding the Trade-offs and Critical Factors

Simply owning a tablet press is not enough to produce quality tablets. The success of the process depends heavily on other factors.

Material Formulation is Crucial

The machine can only compress the material it is given. The powder formulation must have the right properties, such as good flowability to fill the die evenly and proper compressibility to form a strong, stable tablet without cracking.

This is why formulations include excipients—inactive ingredients like binders, fillers, and lubricants—that ensure the powder behaves correctly under pressure.

The Importance of Tooling

The design and quality of the punches and dies (collectively known as "tooling") are critical. Poorly maintained or improperly designed tooling can lead to common tablet defects like sticking, capping (top of the tablet splitting off), or lamination.

Operational Complexity and Safety

Industrial tablet presses are powerful and complex machines. They require skilled operators to set up the tooling, calibrate the fill depth and compression force, and monitor production to ensure quality. The immense forces involved also make strict safety protocols essential.

Matching the Machine to the Goal

The right equipment directly corresponds to the intended scale and purpose of the operation.

- If your primary focus is research and development: A single-station tablet press provides the precision and control needed for testing new formulations and creating small test batches.

- If your primary focus is small-scale or custom production: A manual or semi-automatic single-station press offers a cost-effective solution for producing limited quantities, such as for nutraceuticals or specialized supplements.

- If your primary focus is large-scale industrial manufacturing: A high-speed rotary tablet press is the essential equipment for achieving the volume, consistency, and efficiency required in the pharmaceutical industry.

Understanding the mechanics of tablet compression is the first step toward producing consistent, high-quality products, regardless of the scale of your operation.

Summary Table:

| Press Type | Best For | Key Characteristics |

|---|---|---|

| Single-Station Press | R&D, Small Batches | One tablet at a time, high precision, ideal for formulation testing |

| Rotary Press | Industrial Manufacturing | High-speed, multiple stations, produces thousands of tablets per hour |

Ready to scale your tablet production? Whether you're in R&D or full-scale manufacturing, KINTEK has the right tablet press for your needs. Our expertise in lab equipment ensures you get a machine that delivers precise dosage, uniform hardness, and reliable performance. Contact our experts today to find the perfect press for your pharmaceutical or nutraceutical laboratory!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What components of a tablet press define the size and shape of the tablets? Mastering Die and Punch Tooling

- What is the function of a tablet press? Transforming Powder into Precise, Uniform Tablets

- What is the purpose of the pelletizing machine? Transform Waste into Valuable, Dense Pellets

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What are the steps of tablet production by direct compression? Streamline Your Manufacturing Process

- What are pill presses called? The Correct Term is Tablet Press for Pharmaceutical Manufacturing

- Which type of tablet press is more suitable for large scale production? Rotary Presses for High-Volume Efficiency

- What is the difference between pelleting and pelletizing? Understand the Core Agglomeration Methods