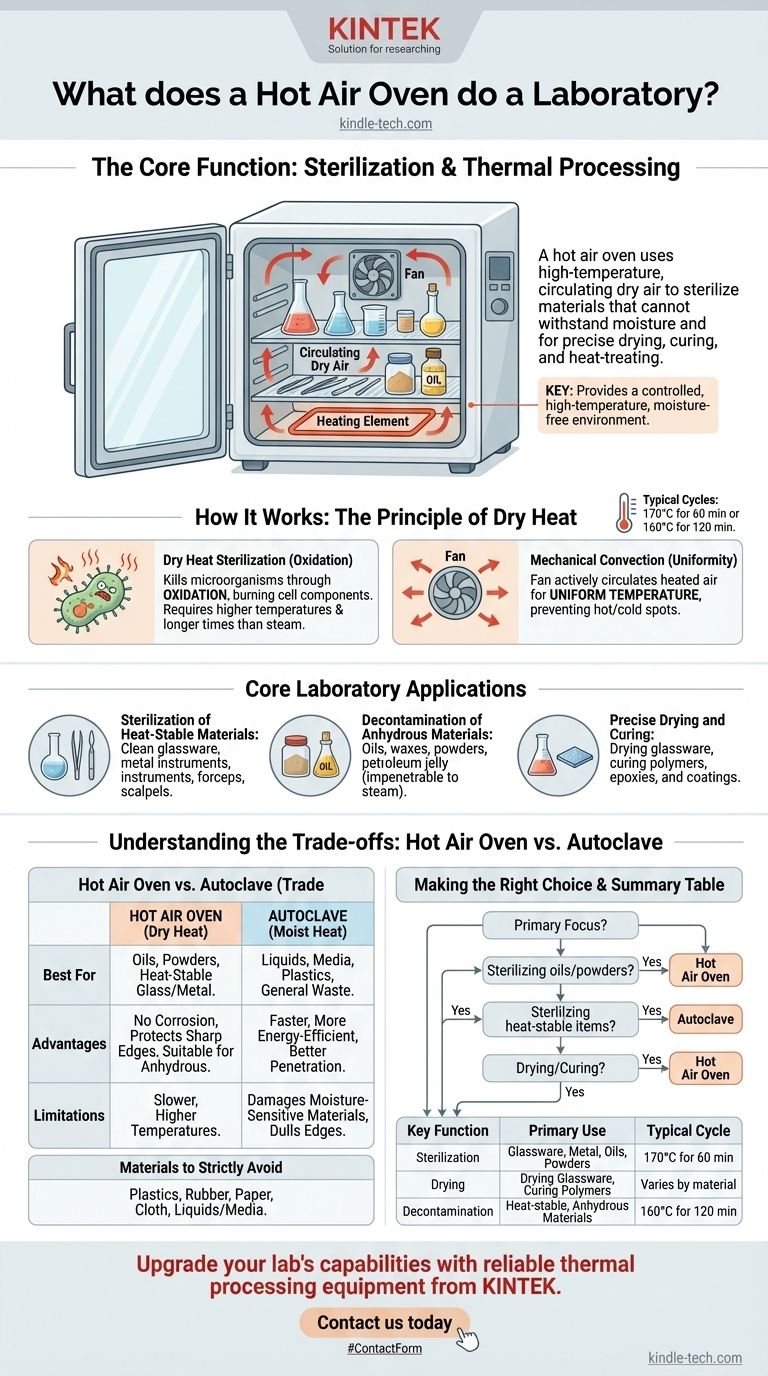

In a laboratory, a hot air oven is a fundamental piece of equipment for sterilization and thermal processing. It uses high-temperature, circulating dry air to sterilize materials that cannot withstand the moisture of an autoclave, such as glassware, metal instruments, powders, and oils. Beyond sterilization, it is also used for precise drying, curing, and heat-treating of various substances.

The core function of a hot air oven is to provide a controlled, high-temperature, and moisture-free environment. This makes it the essential choice for applications where steam is either ineffective or would damage the material being processed.

How a Hot Air Oven Works

A hot air oven is conceptually simple but operates on precise principles to ensure consistent and reliable results. Its effectiveness hinges on the properties of dry heat and air circulation.

The Principle of Dry Heat Sterilization

Unlike an autoclave which uses moist heat (steam) to denature proteins, a hot air oven uses dry heat to kill microorganisms. This process works primarily through oxidation, effectively burning and destroying essential cell components.

This method requires higher temperatures and longer exposure times than steam sterilization because dry air is less efficient at transferring heat into and through materials.

The Role of Mechanical Convection

Modern laboratory ovens use mechanical convection, meaning a fan actively circulates the heated air inside the chamber. This is critical for ensuring a uniform temperature throughout the entire space.

Without a fan, "hot spots" and "cold spots" would develop, leading to unreliable sterilization or inconsistent drying results.

Typical Temperature and Time Cycles

For sterilization, common cycles include operating at 170°C (340°F) for 60 minutes or 160°C (320°F) for 120 minutes. The timer only begins once the oven has reached the target temperature.

Drying or curing applications will use a wide range of temperatures and times specific to the material and protocol.

Core Laboratory Applications

The unique properties of a hot air oven make it indispensable for several key tasks that other equipment, like an autoclave, cannot perform.

Sterilization of Heat-Stable Materials

Hot air ovens are ideal for sterilizing clean glassware (like flasks, pipettes, and petri dishes) and heat-stable metal instruments (such as forceps and scalpels).

Decontamination of Anhydrous Materials

This is a primary use case. Materials that are impenetrable to steam or would be damaged by moisture must be sterilized with dry heat. This includes oils, waxes, powders, and petroleum jelly.

Precise Drying and Curing

The oven provides a stable, high-temperature environment perfect for thoroughly drying washed laboratory glassware to prevent contamination. It is also used in material science and chemistry to cure polymers, epoxies, and other coatings that require specific thermal processing.

Understanding the Trade-offs: Hot Air Oven vs. Autoclave

Choosing between a hot air oven and an autoclave is a common decision point in a lab. The choice depends entirely on the material being processed.

Why Choose a Hot Air Oven?

A hot air oven is the superior or only choice for sterilizing oils and powders. Furthermore, the dry environment prevents the corrosion of metal instruments and does not dull the sharp edges of scalpels, unlike the repeated exposure to steam in an autoclave.

Key Limitations

The primary limitation is its inefficiency compared to an autoclave. Dry heat sterilization is slower and requires higher temperatures, making it less energy-efficient for materials that can tolerate steam.

Materials to Strictly Avoid

You must never place certain items in a hot air oven. These include most plastics and rubber goods, which will melt at sterilization temperatures. Paper and cloth products will char, and liquids or biological media will simply boil away.

Making the Right Choice for Your Application

Selecting the correct heating method is critical for ensuring the integrity of both your materials and your experimental results.

- If your primary focus is sterilizing oils, powders, or moisture-sensitive chemicals: The hot air oven is the only correct tool for the job.

- If your primary focus is sterilizing heat-stable glassware or metal instruments: A hot air oven is highly effective and protects sharp edges, though an autoclave may be faster if available and suitable.

- If your primary focus is general-purpose sterilization of liquids, media, or plastics: The autoclave is the standard and most efficient method.

- If your primary focus is drying or heat-curing materials: The hot air oven is specifically designed for providing the precise, stable, and dry thermal environment required.

Understanding the principles of dry heat empowers you to leverage the hot air oven for safe, effective, and reliable results in the laboratory.

Summary Table:

| Key Function | Primary Use | Typical Cycle |

|---|---|---|

| Sterilization | Glassware, metal instruments, oils, powders | 170°C for 60 minutes |

| Drying | Drying washed glassware, curing polymers | Varies by material |

| Decontamination | Heat-stable, anhydrous materials | 160°C for 120 minutes |

Upgrade your lab's capabilities with reliable thermal processing equipment from KINTEK.

Our hot air ovens are engineered for precise temperature control and uniform air circulation, ensuring effective sterilization and drying for your glassware, metal instruments, powders, and oils. Whether you need to sterilize moisture-sensitive materials or require consistent drying for your protocols, KINTEK has the solution.

Contact us today to find the perfect hot air oven for your laboratory's unique needs and enhance your efficiency and results.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the pressure required in an autoclave? Achieve Sterile Results with 15 PSI

- What is an example of autoclave in laboratory? Essential Sterilization for Reliable Science

- What are the maintenance procedures for autoclave? Ensure Sterilization Safety and Reliability

- What is autoclave in laboratory? Achieve Total Sterility for Your Lab

- What lab supplies should be autoclaved? A Guide to Safe Sterilization and Decontamination