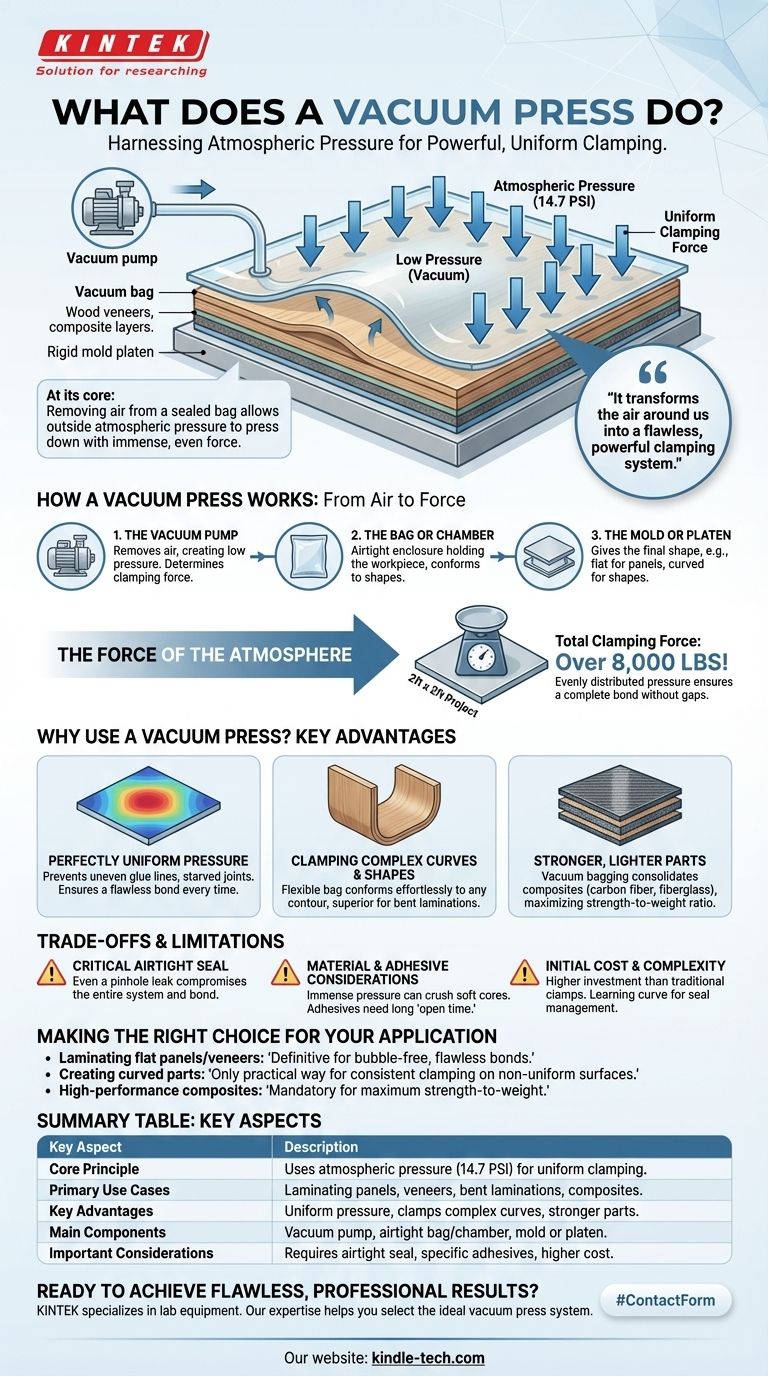

At its core, a vacuum press uses atmospheric pressure as a powerful and uniform clamp. By removing air from a sealed bag or chamber containing materials, it causes the weight of the outside atmosphere to press down with immense force. This process is essential for laminating layers, applying veneers, and molding complex shapes for items ranging from fine furniture to high-performance skateboards.

A vacuum press isn't about "sucking" materials together; it's about removing the air between them so the planet's atmosphere can "push" them together with perfectly even pressure. It transforms the air around us into a flawless, powerful clamping system.

How a Vacuum Press Works: From Air to Force

A vacuum press leverages a fundamental principle of physics to achieve what is difficult or impossible with mechanical clamps. The system is elegant in its simplicity but profound in its application.

The Core Principle: Pressure Differential

A vacuum press works by creating a pressure differential. The vacuum pump removes air molecules from inside a sealed, airtight bag.

This doesn't create a "sucking" force. Instead, it eliminates the air pressure inside the bag that was pushing outwards. The constant atmospheric pressure outside the bag—approximately 14.7 pounds per square inch (PSI) at sea level—is now unopposed and exerts its full force on the bag's exterior surface.

The Key Components

Every vacuum press system consists of three primary parts:

- The Vacuum Pump: The engine of the system, responsible for removing air and creating the low-pressure environment. The level of vacuum determines the clamping force.

- The Bag or Chamber: An airtight enclosure, typically a flexible vinyl or polyurethane bag, that holds the workpiece. Its flexibility allows it to conform to any shape.

- The Mold or Platen: The rigid form that gives the workpiece its final shape. For flat panels, this is simply a flat surface. For curved items, it is a precisely shaped mold.

The Force of the Atmosphere

The amount of force generated is staggering. On a small 2-foot by 2-foot project, the total clamping force is over 8,000 pounds. This immense, evenly distributed pressure forces layers of wood, composite, or other materials together, squeezing out excess glue and ensuring a complete bond without gaps.

Why Use a Vacuum Press? The Key Advantages

The benefits of a vacuum press go far beyond just clamping. It enables a higher level of precision and quality in fabrication.

Perfectly Uniform Pressure

Mechanical clamps concentrate force only at the point of contact. This can lead to an uneven glue line, starved joints in some areas, and weak bonds in others. A vacuum press applies uniform pressure across every square inch of the surface, ensuring a perfect, consistent bond.

Clamping Complex Curves and Shapes

Attempting to clamp a complex curve with mechanical clamps is a frustrating exercise in geometry. A flexible vacuum bag, however, effortlessly conforms to any contour, from gentle arcs to intricate forms. This makes it the superior method for bent laminations and shaping composites.

Stronger, Lighter Parts

The consistent, high pressure of a vacuum press is critical for working with composites like fiberglass, Kevlar, and carbon fiber. The process, known as vacuum bagging, consolidates the composite layers and removes excess epoxy resin. This maximizes fiber content, dramatically increasing the part's strength-to-weight ratio.

Understanding the Trade-offs and Limitations

While powerful, a vacuum press is a specific tool with its own set of challenges that require attention to detail.

The Critical Importance of the Seal

The entire system's effectiveness depends on an airtight seal. Even a pinhole leak in the bag or a faulty seal at the closure will cause the pump to cycle continuously and fail to maintain full pressure, compromising the bond.

Material and Adhesive Considerations

The immense pressure can crush soft core materials if not managed correctly. Furthermore, the adhesive used must have a long enough "open time" to allow for assembling the parts and sealing the bag before the glue begins to set.

Initial Cost and Complexity

A professional-grade vacuum press system, including the pump and a durable bag, represents a more significant investment than a set of traditional clamps. The process also has a learning curve related to managing bag seals, resin flow, and vacuum levels.

Making the Right Choice for Your Application

Choosing to use a vacuum press depends entirely on your project's goals for quality, shape, and performance.

- If your primary focus is laminating flat panels or applying veneer: A vacuum press is the definitive method for achieving a bubble-free, flawless bond that is impossible to guarantee with other techniques.

- If your primary focus is creating curved parts or complex shapes: A vacuum press provides the only practical way to apply consistent clamping pressure across non-uniform surfaces for strong, reliable results.

- If your primary focus is high-performance composites: A vacuum press is not just an option but a mandatory tool for achieving the maximum strength-to-weight ratio required in aerospace, marine, and sporting goods applications.

By mastering the principle of atmospheric pressure, a vacuum press transforms a simple bag and pump into a powerful and precise manufacturing tool.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses atmospheric pressure (14.7 PSI) to create immense, uniform clamping force by removing air from a sealed bag. |

| Primary Use Cases | Laminating panels, applying veneers, bent laminations, and consolidating high-performance composites (carbon fiber, fiberglass). |

| Key Advantages | Perfectly uniform pressure, ability to clamp complex curves, and creation of stronger, lighter composite parts. |

| Main Components | Vacuum pump, airtight bag/chamber, and a mold or platen. |

| Important Considerations | Requires an airtight seal, specific adhesives with long open time, and represents a higher initial investment than traditional clamps. |

Ready to Achieve Flawless, Professional Results?

Whether you're laminating fine furniture veneers, creating complex curved parts, or building high-performance composite components, the right vacuum press is the key to superior quality and strength.

KINTEK specializes in lab equipment and consumables, serving precise laboratory and workshop needs. Our expertise can help you select the ideal vacuum press system for your specific application, ensuring you get the perfect, uniform pressure required for a flawless bond every time.

Contact us today using the form below to discuss your project requirements and discover how a KINTEK vacuum solution can elevate your work.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the applications of hot pressing? Create High-Density, High-Performance Materials

- What are the advantages of a vacuum hot press furnace for W-50%Cu? Achieve 99.6% Density at Lower Temperatures

- What role does Spark Plasma Sintering (SPS) play in Ti-Nb-Zr alloys? Achieve High Strength & Biocompatibility

- What are the advantages of using a vacuum hot pressing furnace? Superior Densification for 2024Al/Gr/SiC Composites

- What are the benefits of using a hybrid SPS and HP system for Al-doped LLZO? Unlock Precision Densification Control

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control

- What is the necessity of pre-pressing composite powders? Enhance Stability in Vacuum Hot-Pressing Sintering

- What is the process of hot isostatic pressing? Achieve Maximum Density and Reliability