At its core, CVD stands for Chemical Vapor Deposition. It is a highly controlled process where volatile chemical precursors in a gaseous state react or decompose on the surface of a heated object—called a substrate—to form a solid, high-performance thin film. This method creates a coating that is chemically bonded to the surface, making it exceptionally durable.

Chemical Vapor Deposition is not like painting a surface; it's more like growing a new, functional skin directly onto an object. By using reactive gases and intense heat inside a vacuum chamber, the process creates an extremely pure and hard coating that becomes an integral part of the item itself.

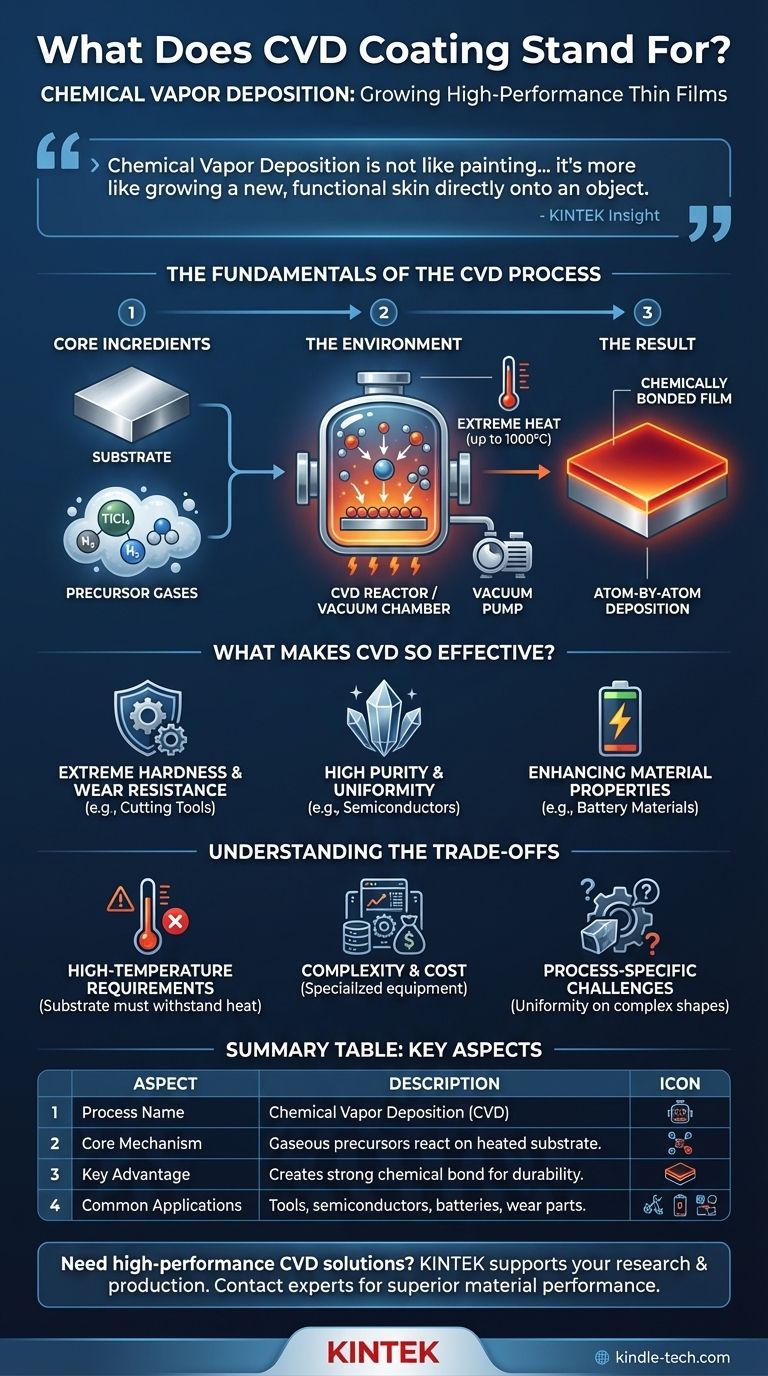

The Fundamentals of the CVD Process

To understand CVD, it's helpful to break it down into its essential components: the ingredients, the environment, and the final reaction. This is a manufacturing process executed at a microscopic level.

The Core Ingredients: Substrate and Precursors

A CVD process begins with two key components. The first is the substrate, which is the object or material to be coated.

The second is a set of precursor gases. These are volatile compounds that contain the elements needed for the final coating. For example, to create a Titanium Nitride (TiN) coating, gases like Titanium Tetrachloride (TiCl₄), Nitrogen (N₂), and Hydrogen (H₂) are introduced into the chamber.

The Environment: Extreme Heat and Vacuum

The entire process takes place inside a sealed CVD reactor or chamber, typically under a vacuum. The vacuum is critical for ensuring the purity of the coating by removing any unwanted gases that could cause contamination.

The substrate is then heated to very high temperatures, often up to 1000°C (1832°F). This intense heat provides the necessary energy to trigger the chemical reactions.

The Result: A Chemically Bonded Film

Once the precursor gases come into contact with the hot substrate, they react or decompose on its surface. This chemical reaction deposits a thin, solid film atom by atom, creating a dense and uniform layer.

Crucially, this new layer is chemically bonded to the substrate. It isn't merely sitting on top; it has become a permanent, integrated part of the surface, which is the source of its remarkable durability.

What Makes a CVD Coating So Effective?

The specific conditions of the CVD process impart unique and valuable properties to the resulting coatings. These attributes make it indispensable in demanding industries from aerospace to electronics.

Extreme Hardness and Wear Resistance

Many CVD coatings, such as Titanium Carbide (TiC) and Titanium Nitride (TiN), are exceptionally hard and resistant to wear. This makes them ideal for extending the life of cutting tools, drills, and other industrial components subjected to intense friction.

High Purity and Uniformity

Because it is a gas-phase process conducted in a vacuum, CVD can produce coatings of extremely high purity. The deposition method allows for a very uniform and controlled thickness across the substrate's surface, which is critical for applications in semiconductors and optics.

Enhancing Material Properties

CVD is not just for creating hard surfaces. It is a versatile tool for enhancing a material's fundamental properties. For instance, applying a thin carbon coating to battery materials like LiFePO₄ can dramatically improve their power density and cycling lifetime.

Understanding the Trade-offs

While powerful, CVD is not a universal solution. Its demanding nature creates specific limitations and trade-offs that must be considered.

High-Temperature Requirements

The primary limitation of CVD is the extreme heat involved. The substrate material must be able to withstand the high reaction temperatures without melting, warping, or losing its essential properties. This makes CVD unsuitable for many plastics, low-melting-point metals, and heat-sensitive components.

Complexity and Cost

CVD requires specialized equipment, including vacuum chambers, precise gas delivery systems, and high-power heating elements. The need to safely handle volatile and sometimes hazardous precursor gases adds to the operational complexity and cost, making it a more expensive process than simpler coating methods.

Process-Specific Challenges

The nature of the gas-phase reaction means that achieving a perfectly uniform coating on highly complex shapes with internal channels or hidden surfaces can be challenging. The process must be carefully tuned for each specific part geometry.

Making the Right Choice for Your Goal

Selecting a coating process depends entirely on the performance requirements and the nature of the component being coated. CVD is a specialized tool for high-value applications.

- If your primary focus is maximum hardness and wear resistance: CVD is an industry standard for parts that can tolerate high heat, such as metal cutting tools and industrial molds.

- If your primary focus is creating a high-purity, functional film: CVD is essential in semiconductor manufacturing and advanced energy applications like batteries and solar cells.

- If your primary focus is absolute adhesion and integration: The chemical bond formed by CVD is superior to most mechanical coating methods, making it ideal when delamination cannot be tolerated.

Ultimately, Chemical Vapor Deposition is a foundational technology for engineering materials with properties that are unachievable in their bulk form.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Name | Chemical Vapor Deposition (CVD) |

| Core Mechanism | Gaseous precursors react on a heated substrate to form a solid film. |

| Key Advantage | Creates a strong chemical bond with the substrate for exceptional durability. |

| Common Applications | Cutting tools, semiconductors, batteries, and wear-resistant components. |

Need a high-performance coating solution for your lab equipment or components? The CVD process can provide the extreme hardness, purity, and adhesion your research or production demands. KINTEK specializes in providing advanced lab equipment and consumables to support your coating and material science needs. Contact our experts today to discuss how we can help you achieve superior material performance.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Laboratory CVD Boron Doped Diamond Materials

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis