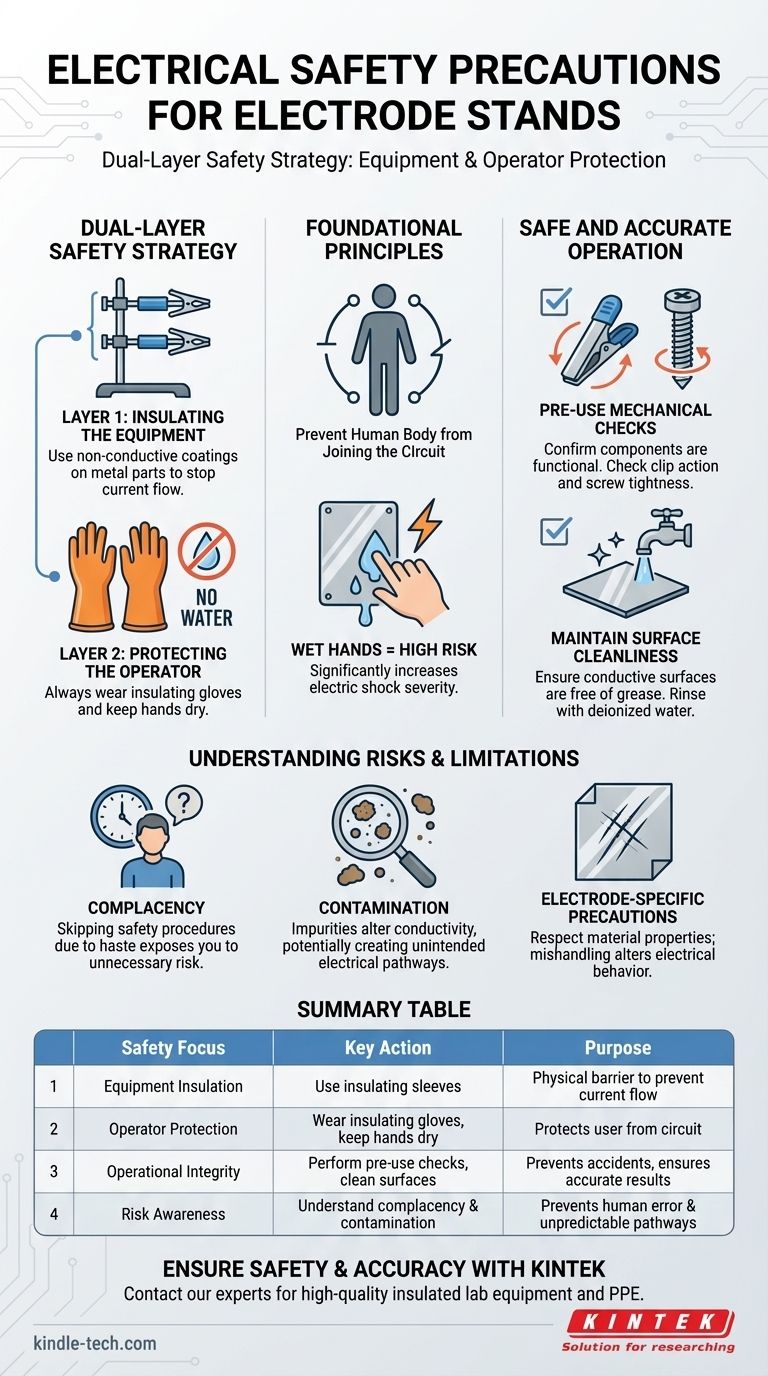

To prevent electric shock, you must implement a dual-layer safety strategy for your electrode stand. This involves physically insulating any conductive metal parts of the stand that could contact a power source and ensuring you, the operator, are personally protected with insulating gloves and by keeping your hands dry at all times.

Your safety depends on creating and maintaining multiple barriers between yourself and the electrical current. The first barrier is insulating the equipment itself; the second is protecting your own body with appropriate personal protective equipment (PPE).

Foundational Electrical Safety Principles

The core of electrical safety in any lab setting is preventing the human body from becoming part of an electrical circuit. With an electrode stand, this requires attention to both the equipment and your personal conduct.

Insulating the Equipment

Any metal component of the stand has the potential to become energized if it comes into contact with the electrolyte or a direct power source.

Use insulating sleeves or other non-conductive coatings on clips, arms, and posts. This creates a physical barrier that stops electricity from flowing through the stand's structure.

Protecting the Operator

Even with insulated equipment, you must assume that an electrical hazard could exist. Your personal safety practices are the final and most critical line of defense.

Always wear insulating gloves during operation. Never touch electrodes, clips, or any metal part of the stand with wet hands, as water drastically lowers your skin's resistance and significantly increases the severity of a potential electric shock.

Ensuring Safe and Accurate Operation

A secure and clean setup is a safer setup. Procedural checks before each use prevent accidents and ensure the integrity of your experiment.

Perform Pre-Use Mechanical Checks

Before mounting a sample, confirm that all components are in good working order.

Check that the clip head opens and closes properly and that all fastening screws are tight. A securely held sample is less likely to slip and cause an accidental short or spill.

Maintain Surface Cleanliness

Contamination can compromise both safety and experimental results.

Ensure the conductive sheet of the electrode holder and the sample surface are clean and free of grease. If dirty, rinse the sheet with deionized water. Avoid touching the sample surface directly to prevent contamination.

Understanding the Risks and Limitations

Effective safety requires understanding not just the rules, but the reasons behind them and the potential points of failure.

The Risk of Complacency

The most common point of failure is human error. Skipping pre-use checks or forgetting to wear gloves because an experiment is "quick" exposes you to unnecessary risk.

Safety procedures are not suggestions; they are mandatory requirements for safe operation.

The Hidden Danger of Contamination

While often viewed as an issue of accuracy, surface contamination can also impact safety.

Impurities can alter the conductivity of surfaces in unpredictable ways, potentially creating unintended electrical pathways that bypass your planned insulation.

Electrode-Specific Precautions

Different electrode materials have unique properties that you must respect. For example, a platinum sheet electrode is soft and easily damaged or contaminated by organic materials. Mishandling not only ruins an expensive component but can also alter its electrical behavior.

Making the Right Choice for Your Goal

Your specific safety focus may change depending on the task at hand, but the principles remain constant.

- If your primary focus is preventing electric shock: Prioritize insulating the stand's metal parts and always wear your insulating gloves.

- If your primary focus is ensuring experimental accuracy: Emphasize pre-use checks for cleanliness and mechanical integrity to guarantee a stable and uncontaminated setup.

- If your primary focus is protecting sensitive electrodes: Handle them with extreme care to avoid physical damage, scratches, or chemical contamination that could alter results.

Ultimately, a rigorous and consistent safety protocol is the foundation for any successful and repeatable scientific work.

Summary Table:

| Safety Focus | Key Action | Purpose |

|---|---|---|

| Equipment Insulation | Use insulating sleeves on clips, arms, and posts. | Creates a physical barrier to prevent current flow through the stand. |

| Operator Protection | Wear insulating gloves; keep hands dry. | Protects the user from becoming part of an electrical circuit. |

| Operational Integrity | Perform pre-use mechanical checks and clean surfaces. | Prevents accidents, slips, and contamination for safe, accurate results. |

| Risk Awareness | Understand risks of complacency and contamination. | Prevents human error and unpredictable electrical pathways. |

Ensure your lab's safety and experimental accuracy with the right equipment. KINTEK specializes in high-quality lab equipment and consumables, including insulated electrode stands and PPE, designed to meet rigorous safety standards. Our products help you create a secure environment for precise scientific work. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance