To choose the right dental sintering furnace, you must evaluate three primary factors: its production capacity, its sintering speed, and its programmability for different materials. These core specifications directly influence your workflow efficiency, the quality of your restorations, and the long-term versatility of your investment.

The goal is not to find the single "best" furnace, but to select the one that precisely matches your specific needs, whether you are a high-volume lab focused on throughput or a chairside clinic prioritizing same-day restorations.

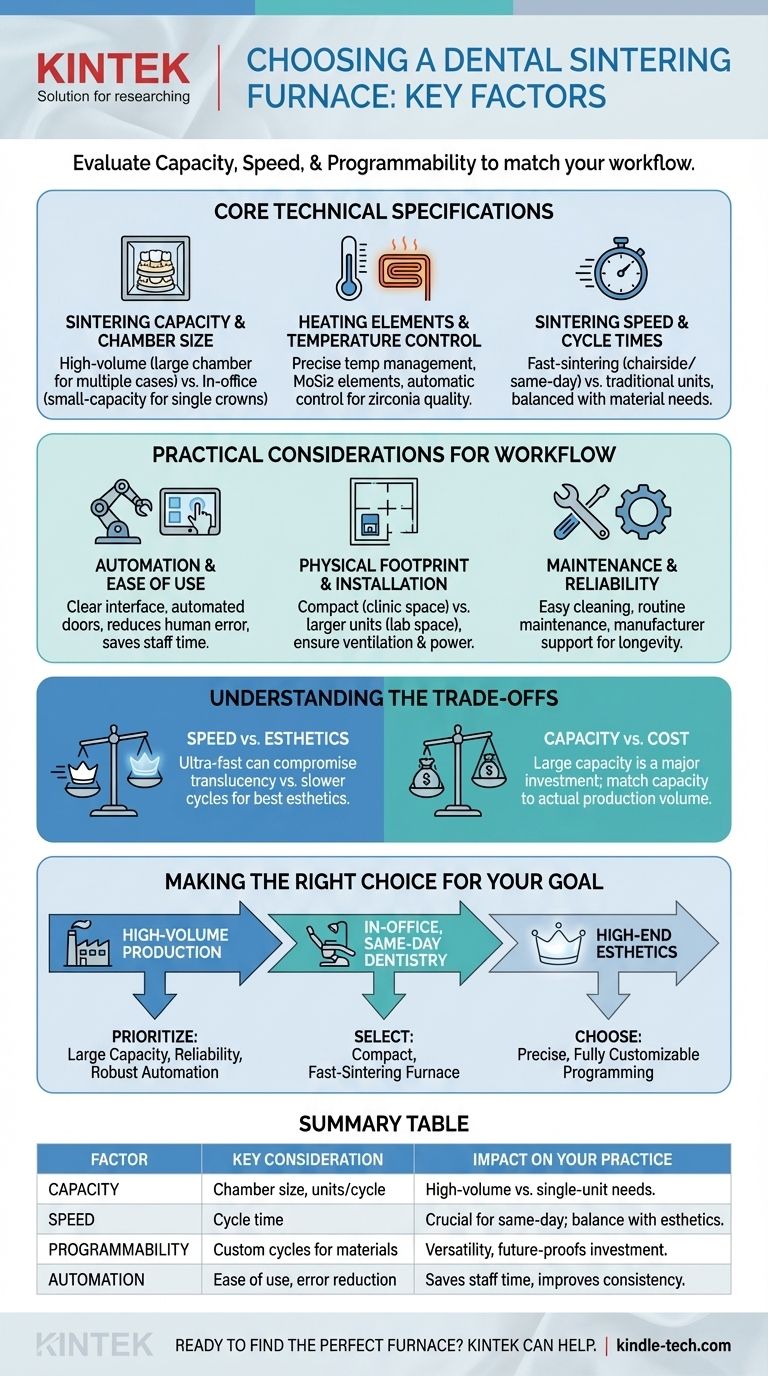

Core Technical Specifications to Evaluate

Choosing a furnace begins with understanding the technical features that define its performance and suitability for your specific applications.

Sintering Capacity and Chamber Size

The capacity of the furnace dictates how many restorations you can process in a single cycle. This is a critical factor for managing workflow and turnaround times.

High-volume production labs require large chambers to sinter multiple cases at once, maximizing efficiency. In contrast, an in-office clinic may only need a small-capacity furnace for single crowns.

Heating Elements and Temperature Control

The quality of zirconia restorations depends on precise temperature management. The furnace must have automatic and programmable temperature control to manage different heating rates and dwell times accurately.

Most modern furnaces use Molybdenum Disilicide (MoSi2) heating elements, which are reliable and capable of reaching the high temperatures required for sintering zirconia without contamination.

Sintering Speed and Cycle Times

Speed is a major consideration, especially for clinics offering chairside or same-day dentistry. Fast-sintering furnaces can complete a cycle for a single crown in a fraction of the time of traditional units.

However, the need for speed must be balanced with the requirements of the specific material being used.

Programmability and Material Versatility

A furnace with pre-programmed cycles simplifies the workflow for common materials. However, the ability to create and save custom programs is essential.

This programmability ensures you can adapt to new materials as they come to market, future-proofing your investment and giving you the flexibility to work with any brand of zirconia.

Practical Considerations for Your Workflow

Beyond the core specs, the day-to-day usability and integration of the furnace into your lab or clinic are just as important.

Automation and Ease of Use

Modern furnaces offer significant automation, minimizing the chance for human error. Look for features like a clear user interface, automated door mechanisms, and simple program selection.

A furnace that is easy to operate saves valuable staff time and reduces the training burden for your team.

Physical Footprint and Installation

Consider the physical size of the unit and where it will fit in your workspace. Ensure you have adequate ventilation and access to the required power supply.

Some compact models are designed specifically for the limited space of a dental clinic, while larger production units require more dedicated lab space.

Maintenance and Reliability

Ease of cleaning and routine maintenance are crucial for the longevity and consistent performance of the furnace.

Investigate the manufacturer's reputation for reliability and the availability of technical support and service in your region. A dependable unit prevents costly downtime.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Speed vs. Esthetics

While speed is attractive, ultra-fast sintering cycles can sometimes compromise the final esthetics, particularly the translucency, of certain zirconia materials.

Labs focused on high-end cosmetic cases may prioritize furnaces that offer slower, more controlled cycles proven to produce the best possible material properties.

Capacity vs. Cost

A large-capacity furnace is a significant investment. For a smaller practice, buying a furnace that is too large results in wasted energy and an inefficient use of capital.

It is more effective to match the furnace capacity closely to your actual daily or weekly production volume.

Making the Right Choice for Your Goal

Your final decision should be driven by the primary goal of your practice or laboratory.

- If your primary focus is high-volume production: Prioritize a furnace with a large capacity, proven reliability, and robust automation features to maximize throughput.

- If your primary focus is in-office, same-day dentistry: Select a compact, fast-sintering furnace designed for single-unit restorations to optimize chairside workflow.

- If your primary focus is high-end esthetics: Choose a furnace with precise, fully customizable programming to get the absolute best results from specialized zirconia materials.

By aligning these factors with your specific operational needs, you can select a furnace that will function as a long-term asset for your practice.

Summary Table:

| Factor | Key Consideration | Impact on Your Practice |

|---|---|---|

| Capacity | Chamber size and number of units per cycle | High-volume labs need large capacity; clinics may only need single-unit processing. |

| Speed | Cycle time for sintering | Crucial for same-day dentistry; balance with material requirements for esthetics. |

| Programmability | Custom cycles for different materials | Ensures versatility and future-proofs your investment for new zirconia brands. |

| Automation | Ease of use and error reduction | Saves staff time, reduces training, and improves consistency. |

Ready to find the perfect dental sintering furnace for your specific needs?

At KINTEK, we specialize in providing high-quality lab equipment, including dental sintering furnaces tailored for laboratories and clinics. Whether you prioritize high-volume production, chairside speed, or superior esthetics, our experts can help you select a furnace that enhances your workflow, improves restoration quality, and maximizes your investment.

Contact our team today for a personalized consultation and discover the KINTEK difference in reliability and support!

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- Why do ceramics need to be sintered? Unlock Strength and Durability Through High-Temperature Fusion

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What are the primary functions of a laboratory oven in MnO2-GAC synthesis? Optimize Your Catalyst Preparation

- What is ashing in chemistry? Enhance Analytical Accuracy with Ashing Techniques

- What is the importance of precise programmed temperature control in a high-temperature furnace? Master Co-Sintering