After sintering, the initial collection of powder particles is transformed into a single, dense, and solid mass. This process fundamentally improves the material's mechanical properties by fusing the particles together through atomic diffusion, creating a robust component with its final, intended dimensions.

The core outcome of sintering is the conversion of a fragile, loosely-bound "green" part into a strong, densified component. This is achieved by eliminating the pores between particles, which causes predictable shrinkage and a significant increase in mechanical strength.

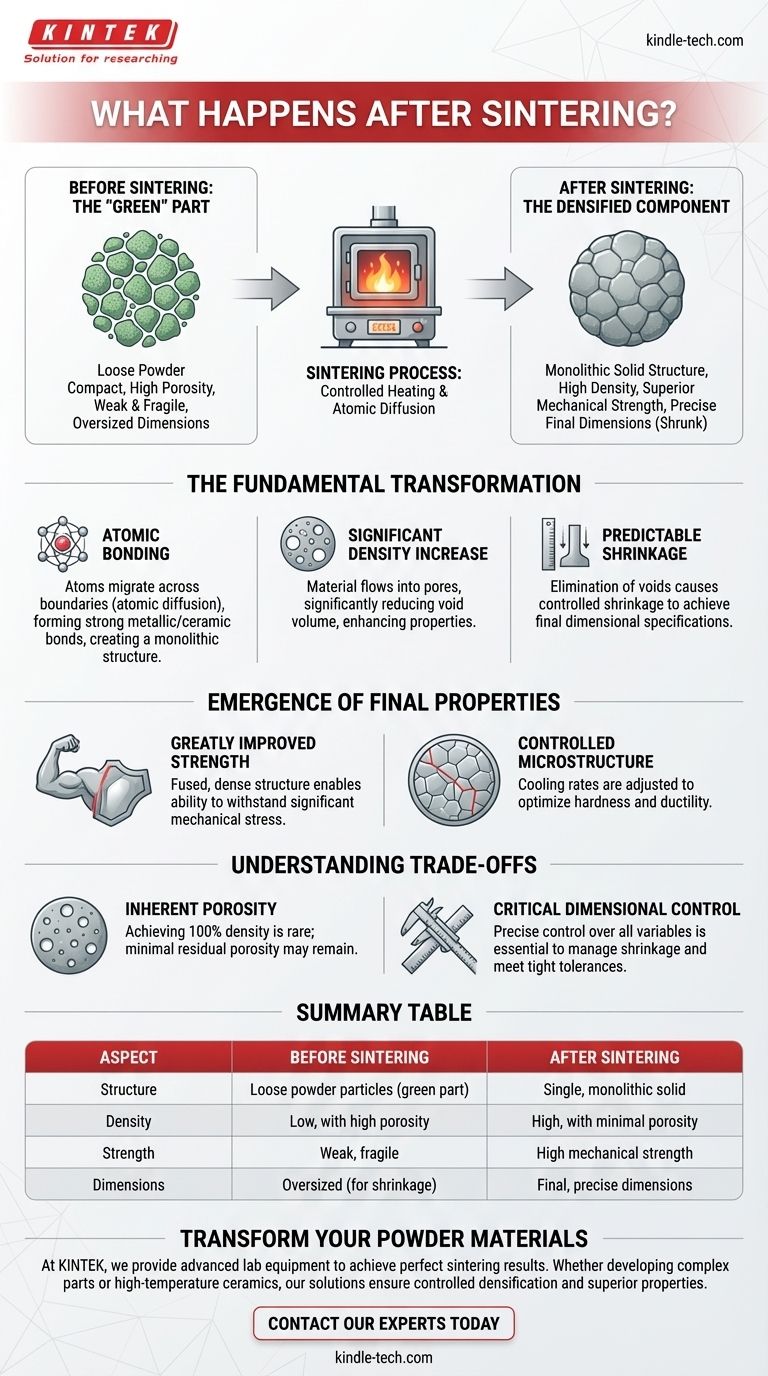

The Fundamental Transformation: From Powder to Solid

Sintering is not merely heating; it is a controlled process that fundamentally re-engineers the material's internal structure. It takes a compacted powder, which is held together by weak mechanical forces, and turns it into a true solid.

Atomic Bonding Creates a Monolithic Structure

At temperatures below the material's melting point, atoms become highly active. They migrate across the boundaries of individual particles in a process called atomic diffusion.

This migration forms strong metallic or ceramic bonds, effectively erasing the original boundaries. The collection of individual particles fuses into a single, continuous, solid piece.

Density Significantly Increases

The initial "green" part, even after being compacted, is filled with tiny voids or pores between the particles. During sintering, material flows into these empty spaces.

As the pores diminish or close up completely, the part becomes significantly denser. This increase in density is a primary reason for the material's improved properties.

The Part Shrinks to Its Final Dimensions

The elimination of internal voids directly results in a decrease in the part's overall volume. This shrinkage is a crucial and predictable outcome of the process.

Engineers account for this shrinkage during the initial design phase to ensure the final sintered component meets precise dimensional specifications.

The Emergence of Final Material Properties

The structural changes that occur during sintering directly translate into the final engineering properties of the finished component.

Greatly Improved Mechanical Strength

The fused, dense structure is far stronger and more durable than the initial powder compact. The new atomic bonds create a solid that can withstand significant mechanical stress.

This transformation from a fragile object to a robust part is the primary goal of the sintering process in manufacturing.

A Controlled Microstructure

The cooling rate after the peak sintering temperature can be carefully controlled. This allows for fine-tuning of the material's final microstructure.

By adjusting the cooling, properties like hardness and ductility can be optimized for the specific application, similar to traditional heat treatment.

Understanding the Trade-offs

While powerful, the sintering process has inherent characteristics and challenges that must be managed for successful outcomes.

Inherent Porosity

Although sintering drastically increases density, achieving 100% theoretical density is often impractical. Some minimal, residual porosity may remain in the final part.

This controlled porosity can sometimes be a desired feature, but in high-performance applications, it can be a limiting factor for ultimate strength.

Dimensional Control is Critical

Because shrinkage is a core part of the process, it must be perfectly calculated and managed. Any variations in powder composition, compaction pressure, or furnace temperature can affect the final dimensions.

Achieving tight tolerances requires precise control over every step leading up to and during the sintering cycle.

How to Apply This to Your Goal

Understanding the outcome of sintering helps clarify why it is chosen for specific manufacturing challenges.

- If your primary focus is creating strong, complex metal parts: Sintering provides the essential densification and strength after an initial shaping process like powder pressing or metal injection molding.

- If your primary focus is working with high-temperature materials: Sintering is the key method for consolidating materials like ceramics or tungsten into a usable solid form without having to reach their extremely high melting points.

- If your primary focus is achieving precise final dimensions with minimal waste: The predictable shrinkage during sintering is a critical design feature that allows for the creation of net-shape parts that require little to no subsequent machining.

Ultimately, sintering is the crucial finishing step that transforms a fragile powder compact into a robust and functional engineering component.

Summary Table:

| Aspect | Before Sintering | After Sintering |

|---|---|---|

| Structure | Loose powder particles (green part) | Single, monolithic solid |

| Density | Low, with high porosity | High, with minimal porosity |

| Strength | Weak, fragile | High mechanical strength |

| Dimensions | Oversized (to account for shrinkage) | Final, precise dimensions |

Ready to transform your powder materials into high-performance components?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to achieve perfect sintering results. Whether you are developing complex metal parts, working with high-temperature ceramics, or aiming for net-shape precision, our solutions ensure controlled densification, predictable shrinkage, and superior final properties.

Let our expertise in sintering technology enhance your laboratory's capabilities. Contact our experts today to discuss your specific application and discover the right equipment for your needs.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is ashing in mineral analysis? Key Steps for Accurate Elemental Analysis

- Why Use a Programmed Muffle Furnace for Plastic-Derived Carbon? Master Precision for Superior Yield & Structure

- Why is a muffle furnace required for gold nanoparticle calcination? Optimize Catalyst Activation & Stability

- Why is a High-Temperature Box Furnace Required for LATP Synthesis? Master NASICON-Type Ceramic Crystal Precision

- What role does a high-temperature box-type muffle furnace play in the preparation of ACN? Expert Synthesis Guide

- Is muffle furnace a vacuum? Choosing the Right High-Temperature Solution for Your Lab

- What role does a high-temperature muffle furnace play in FM steel heat treatment? Expert Microstructure Engineering

- What is the purpose of using vacuum ovens for degassing Alumina/MWNT composites? Ensure Flawless Structural Integrity