At its core, freeze-drying is a technology for preservation. It serves a surprisingly diverse range of industries, from pharmaceuticals and biotechnology to specialty food, pet nutrition, and scientific research. Its value lies in its unique ability to remove water from a product without damaging its delicate structure, nutritional content, or biological activity.

Freeze-drying isn't just about making things last longer; it's about preserving value. Whether that value is the nutritional integrity of food, the therapeutic efficacy of a vaccine, or the chemical structure of a scientific sample, the technology's primary benefit is locking in quality by gently removing water.

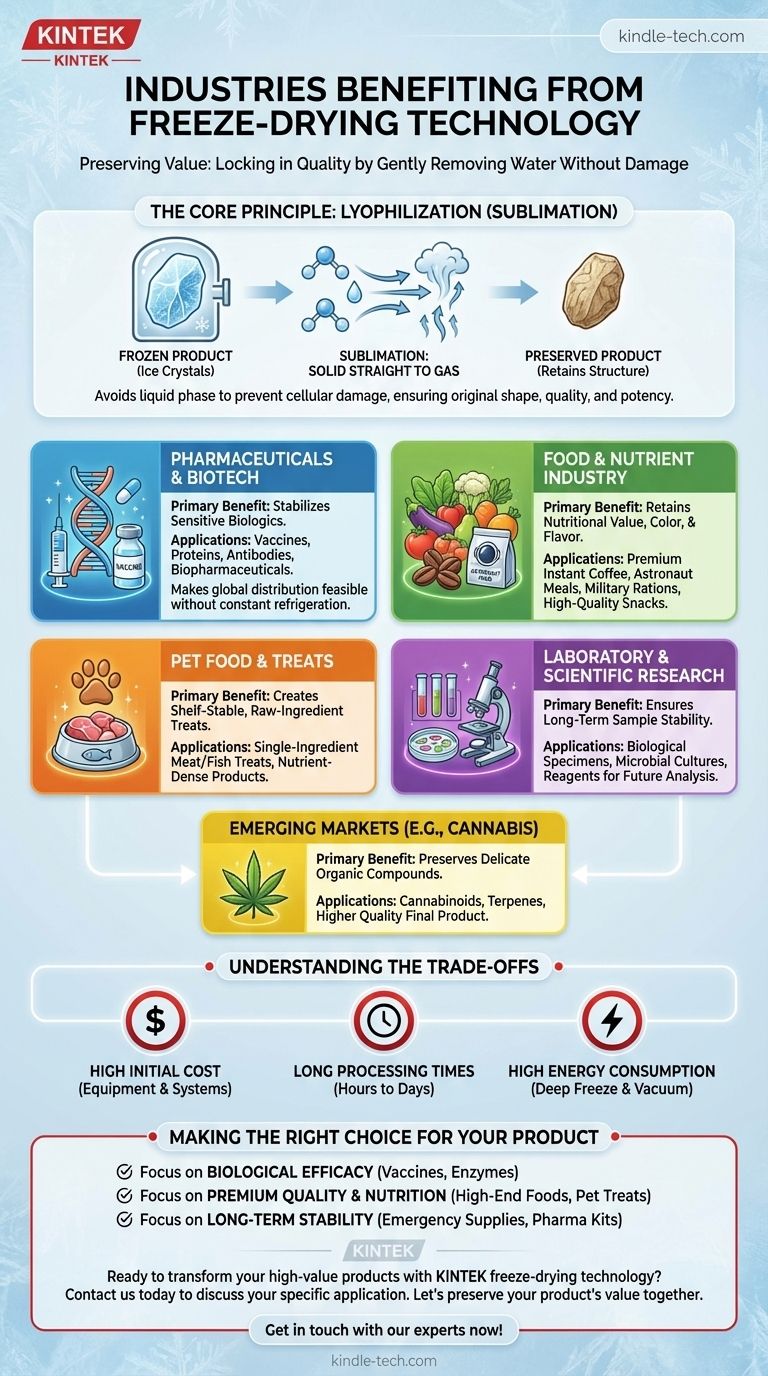

The Core Principle: Why It Works

The technical term for freeze-drying is lyophilization. Unlike simple dehydration, which uses heat that can degrade a product, freeze-drying works through a process called sublimation.

From Solid Straight to Gas

First, the product is frozen solid. Then, under a strong vacuum, the frozen water crystals are turned directly into water vapor, completely bypassing the liquid phase.

Preserving Delicate Structures

Avoiding a liquid water phase is critical. It prevents the cellular or molecular structure from being damaged, which is what typically happens during conventional drying. This gentle process is why freeze-dried products retain their original shape, quality, and potency.

Key Applications Across Industries

The benefits of lyophilization are not universal; they are most pronounced in fields dealing with high-value or sensitive materials.

Pharmaceuticals and Biotechnology

This is arguably the most critical application. Freeze-drying is essential for creating stable, long-lasting formulations of sensitive biological products.

This includes vaccines, proteins, antibodies, and other biopharmaceuticals that would otherwise require constant refrigeration and have a very short shelf life. The technology makes distribution and storage feasible on a global scale.

The Food and Nutrient Industry

While not used for all foods due to cost, freeze-drying is the gold standard for preserving high-value products where quality is paramount.

It maintains the nutritional value, color, and flavor of ingredients far better than other methods. This is why it's used for premium instant coffee, astronaut meals, military rations, and high-quality fruit and vegetable snacks.

Pet Food and Treats

The "humanization" of pet food has created a massive market for high-quality, nutrient-dense products.

Freeze-drying allows for the creation of raw or single-ingredient pet treats that are shelf-stable yet retain the full nutritional profile of the original meat or fish, appealing to discerning pet owners.

Laboratory and Scientific Research

In a research context, the long-term stability of samples is non-negotiable.

Lyophilization is used to preserve biological specimens, microbial cultures, and reagents for future analysis, ensuring that the samples remain unchanged over time.

Emerging and Niche Markets

The versatility of freeze-drying allows it to be adopted by new industries seeking to improve product quality.

The cannabis industry, for example, uses it to preserve cannabinoids and terpenes, resulting in a higher-quality final product compared to traditional curing methods. This highlights its potential for any field with delicate organic compounds.

Understanding the Trade-offs

Despite its benefits, freeze-drying is not the solution for every application. It involves significant trade-offs that make it unsuitable for low-margin, bulk commodities.

High Initial Cost

Lyophilizers and the associated vacuum and refrigeration systems represent a significant capital investment compared to conventional ovens or dehydrators.

Long Processing Times

The process is inherently slow. A single freeze-drying cycle can take many hours or even several days to complete, limiting throughput.

High Energy Consumption

Maintaining a deep freeze and a strong vacuum is an energy-intensive process, leading to higher operational costs per unit compared to heat-based drying.

Making the Right Choice for Your Product

Deciding if freeze-drying is the appropriate technology for your application depends entirely on your primary goal and whether the end-product's value justifies the cost.

- If your primary focus is preserving biological efficacy: Freeze-drying is the gold standard for vaccines, enzymes, and therapeutic proteins where even minor degradation is unacceptable.

- If your primary focus is premium quality and nutritional value: For high-end foods, supplements, or pet treats, this method justifies its cost by delivering a demonstrably superior product.

- If your primary focus is long-term, non-refrigerated stability: It is the ideal choice for creating shelf-stable products, from emergency food supplies to pharmaceutical kits, that must remain viable for years.

Ultimately, freeze-drying empowers industries to transform perishable, high-value materials into stable, high-quality products.

Summary Table:

| Industry | Primary Benefit | Common Applications |

|---|---|---|

| Pharmaceuticals & Biotech | Stabilizes sensitive biologics | Vaccines, proteins, antibodies |

| Food & Nutrients | Retains flavor, color, and nutrition | Instant coffee, astronaut meals, fruit snacks |

| Pet Food | Creates shelf-stable, raw-ingredient treats | Single-ingredient meat/fish treats |

| Scientific Research | Ensures long-term sample stability | Biological specimens, microbial cultures |

| Emerging Markets (e.g., Cannabis) | Preserves delicate organic compounds | Cannabinoids, terpenes |

Ready to transform your high-value products with freeze-drying?

At KINTEK, we specialize in providing advanced lab equipment, including freeze-dryers (lyophilizers), to meet the precise needs of laboratories in pharmaceuticals, biotechnology, food science, and research. Our solutions help you preserve the potency, nutritional value, and integrity of your most sensitive materials.

Contact us today to discuss how our freeze-drying technology can benefit your specific application. Let's preserve your product's value together.

Get in touch with our experts now!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

People Also Ask

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is a Laboratory Freeze Dryer and what is its primary function? Achieve Perfect Preservation of Sensitive Materials

- How does freeze drying preserve the nutritional value of food? A Low-Temperature Solution for Maximum Nutrient Retention

- How does freeze drying maintain product quality compared to conventional drying? Preserve Flavor, Nutrients, and Structure

- What is the basic process of freeze drying? A Guide to Lyophilization Stages and Benefits