In short, nearly every industry that creates or uses electronic devices relies on soldering. This fundamental process is the backbone of manufacturing for consumer electronics, automotive systems, aerospace technology, medical devices, and industrial machinery.

Soldering is not merely a manufacturing technique; it is the foundational process that creates the reliable electrical and mechanical connections enabling the function of virtually all modern technology. Understanding its application is understanding how our digital world is physically built.

The Universal Need: Connecting Components

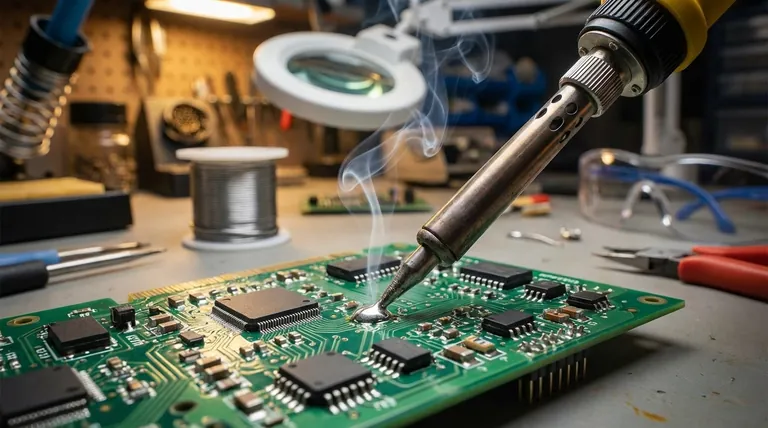

At its core, soldering is a process used to join different materials together by melting a filler metal, known as solder, into the joint. In electronics, this serves a critical dual purpose.

The Role of the Printed Circuit Board (PCB)

Nearly every electronic device is built upon a Printed Circuit Board (PCB). This board acts as the "skeleton" of the device, providing the physical structure and the electrical pathways.

Soldering is the essential step that attaches electronic components—like microchips, resistors, and capacitors—to the PCB, completing the circuit.

Creating a Reliable Connection

A proper solder joint provides two essential functions. First, it ensures excellent electrical conductivity, allowing signals and power to flow with minimal resistance.

Second, it provides a strong mechanical strength, holding the components firmly in place against vibration, shock, and thermal expansion.

A Closer Look at Key Industries

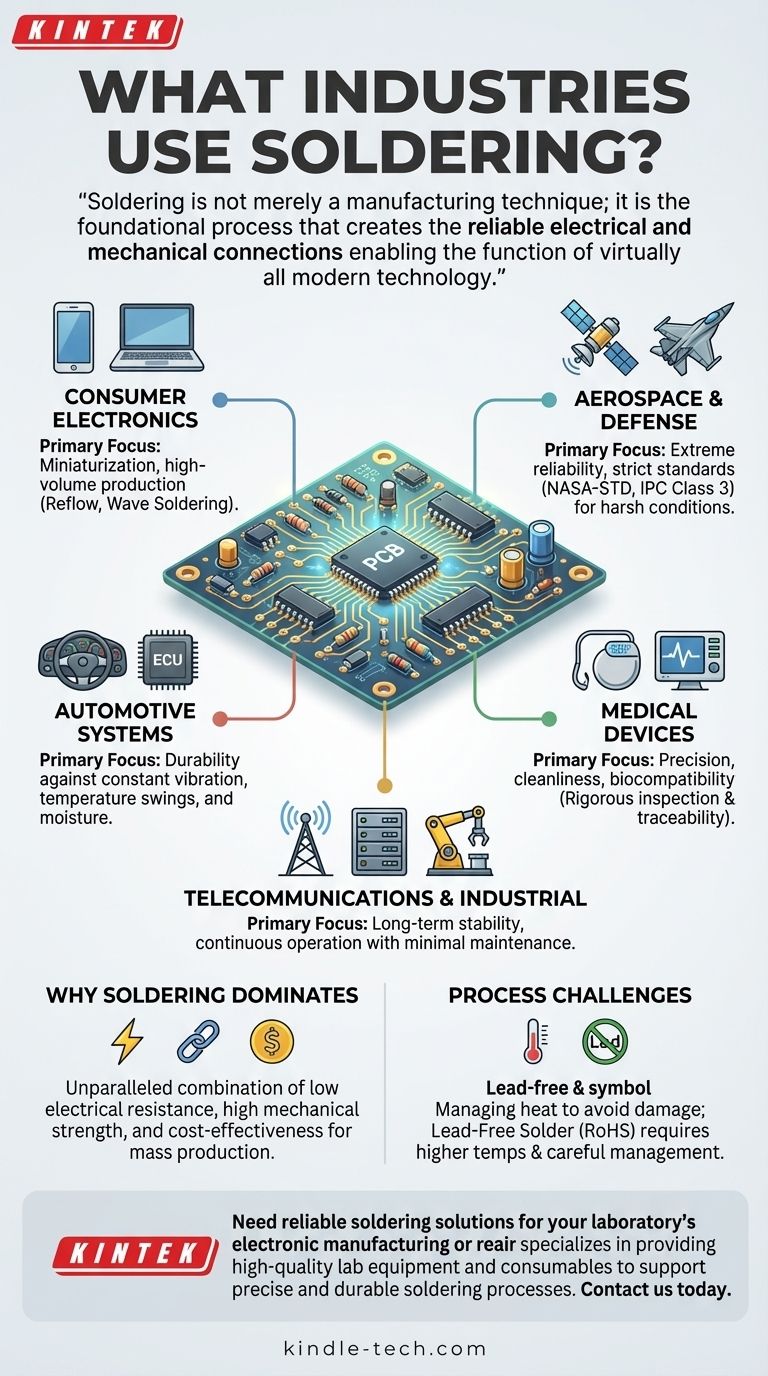

While the principle is the same, the specific demands and standards for soldering vary dramatically depending on the application's environment and criticality.

Consumer Electronics

This is the most visible application of soldering, found in smartphones, laptops, televisions, and gaming consoles. The primary drivers here are miniaturization and high-volume production, often using automated processes like reflow and wave soldering.

Aerospace and Defense

In satellites, aircraft, and military systems, failure is not an option. Soldering in this sector is governed by extremely strict standards (such as NASA-STD and IPC-A-610 Class 3) to ensure absolute reliability under extreme conditions of temperature, vibration, and radiation.

Automotive Systems

Modern vehicles are packed with electronics, from engine control units (ECUs) to infotainment and safety systems. Solder joints in cars must withstand constant vibration, drastic temperature swings, and moisture, demanding a high degree of durability and longevity.

Medical Devices

For devices like pacemakers, infusion pumps, and diagnostic equipment, reliability is a matter of life and death. The soldering process for medical electronics prioritizes precision, cleanliness, and material biocompatibility, with rigorous inspection and traceability.

Telecommunications and Industrial

The infrastructure that powers the internet and industrial automation—such as servers, cell towers, and factory robotics—relies on soldering for long-term stability and performance. These systems are expected to operate continuously for years with minimal maintenance.

Understanding the Trade-offs

Soldering is the dominant method for creating electronic connections, but it's important to understand why it's chosen over alternatives and what its limitations are.

Why Soldering Dominates

Compared to solderless alternatives like press-fit connectors or wire wrapping, soldering provides an unparalleled combination of low electrical resistance, high mechanical strength, and cost-effectiveness for mass production. It creates a permanent, gas-tight joint that protects against corrosion.

Key Process Challenges

The primary challenge is managing heat. Too much heat can damage sensitive electronic components, while too little can result in a "cold" or unreliable joint.

The Rise of Lead-Free Solder

Environmental regulations (like RoHS) have mandated the use of lead-free solders. While better for the environment, these solders typically require higher temperatures and can be more susceptible to forming defects like tin whiskers, presenting new engineering challenges.

Making the Right Choice for Your Goal

The context of the application dictates the soldering priorities. Understanding this allows you to evaluate the quality and purpose of a product's construction.

- If your primary focus is high-volume consumer goods: The goal is maximum automation and speed to achieve the lowest possible cost per unit.

- If your primary focus is high-reliability systems (aerospace, medical): The goal is adherence to strict standards, perfect joint quality, and complete process traceability.

- If your primary focus is repair or prototyping: The goal is manual skill, flexibility, and a deep understanding of how different solders and fluxes interact with components.

Ultimately, soldering is the invisible yet indispensable process that transforms individual components into the functioning electronic systems that define modern life.

Summary Table:

| Industry | Primary Soldering Focus |

|---|---|

| Consumer Electronics | Miniaturization, high-volume production |

| Aerospace & Defense | Extreme reliability, strict standards |

| Automotive | Durability against vibration & temperature |

| Medical Devices | Precision, cleanliness, biocompatibility |

| Telecommunications & Industrial | Long-term stability, continuous operation |

Need reliable soldering solutions for your laboratory's electronic manufacturing or repair? KINTEK specializes in providing high-quality lab equipment and consumables to support precise and durable soldering processes. Whether you're prototyping, conducting R&D, or maintaining critical systems, our tools ensure strong, reliable connections. Contact us today to find the perfect soldering equipment for your specific application and industry standards.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- 12 Inch 24 Inch High Precision Automatic Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- High Precision Diamond Wire Cutting Machine Laboratory Saw Precision Wire EDM Cutting Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts