Before any experiment, your initial inspection of a metal disk electrode must focus on its surface. You are looking for any physical damage—such as scratches, pits, or deformation—and ensuring the surface is impeccably clean. These two factors are paramount, as even minor imperfections can significantly compromise the accuracy and reproducibility of your electrochemical measurements.

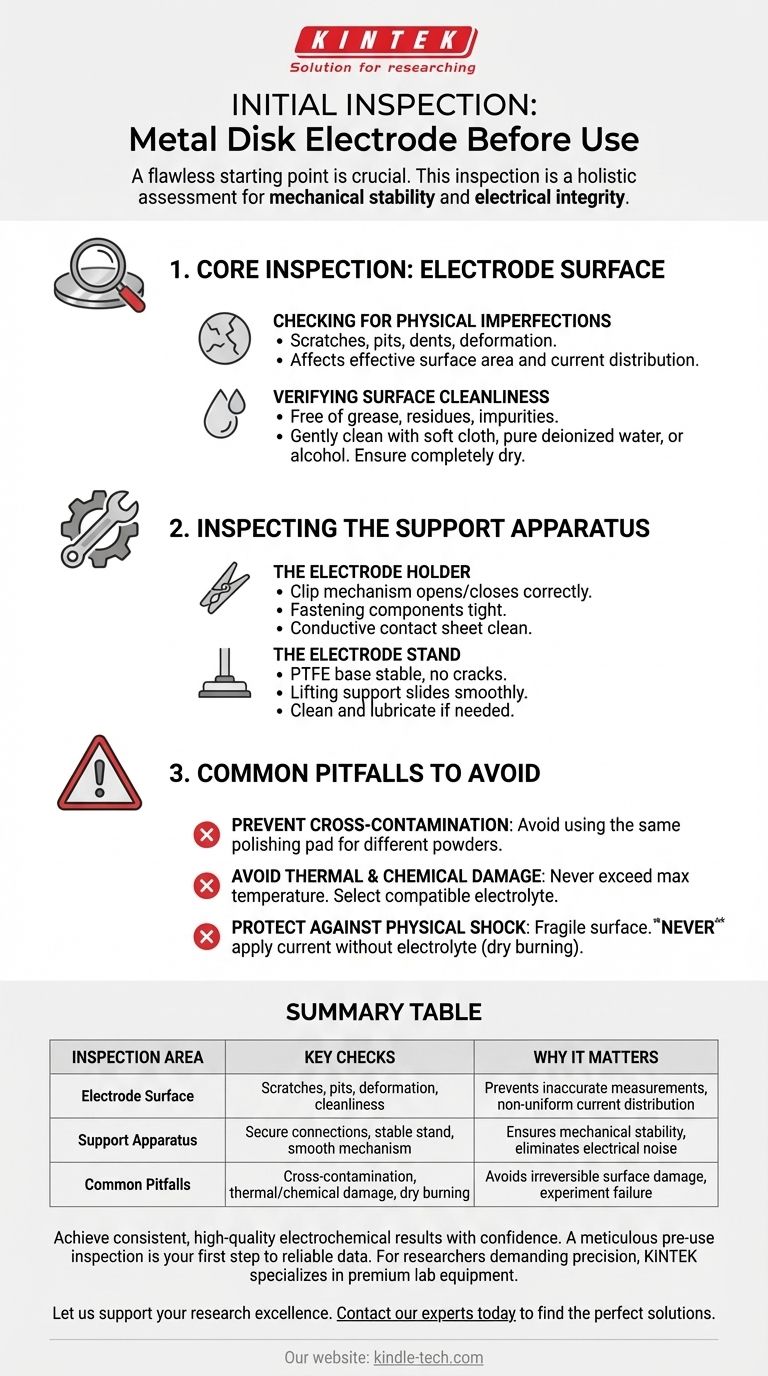

A successful experiment depends on a flawless starting point. The initial inspection is not merely a visual check of the metal disk; it is a holistic assessment of the entire electrode assembly to guarantee both mechanical stability and electrical integrity before you begin.

The Core Inspection: The Electrode Surface

The active surface of the disk is where the electrochemical reaction of interest occurs. Any deviation from a perfectly smooth, clean, and uniform surface can introduce significant error.

Checking for Physical Imperfections

The first step is a close visual examination of the metal disk. Look for any scratches, pits, dents, or other signs of deformation.

These flaws are not just cosmetic. They alter the effective surface area of the electrode and can create non-uniform current distribution, leading to unreliable data.

Verifying Surface Cleanliness

The electrode surface must be completely free of grease, residual polishing compounds, or other impurities. Contamination can block active sites and interfere with the electron transfer process.

If the surface appears dirty, it should be gently cleaned with a soft cloth. For more stubborn residues, pure deionized water or alcohol can be used, but you must ensure the electrode is completely dry before use.

Ensuring Secure Connections

Confirm that all electrical connections to the electrode are tight and secure. A loose connection introduces unwanted resistance and noise into your measurements, which can easily be mistaken for an experimental result.

Inspecting the Support Apparatus

An electrode's performance is also dependent on the stability of its supporting hardware. Problems with the holder or stand can translate directly into noisy or inconsistent data.

The Electrode Holder

The holder is the physical and electrical link to your electrode. Check that its clip mechanism opens and closes correctly to hold the sample securely.

Inspect all fastening components, like screws, to ensure they are tight. Also, verify that the conductive contact sheet within the holder is clean; if not, it can be rinsed with deionized water.

The Electrode Stand

The stand provides mechanical stability. Ensure the PTFE base is stable, without any cracks or deformation.

Test the lifting support to confirm it slides smoothly. If the mechanism is stuck or rough, it should be cleaned of any debris and lubricated sparingly if necessary.

Common Pitfalls to Avoid

A proper inspection also involves being aware of practices that can cause damage. Preventing problems is as crucial as identifying existing ones.

Preventing Cross-Contamination

Strictly avoid using the same polishing pad for different types of polishing powders. This is a common source of cross-contamination that can alter the electrode's surface chemistry and ruin your experiment.

Avoiding Thermal and Chemical Damage

Never exceed the electrode's specified maximum temperature. For chemical compatibility, always select an appropriate electrolyte for your electrode material—for example, avoid chloride-containing solutions with gold electrodes or strong acids with iron electrodes.

Protecting Against Physical Shock

The electrode surface is often fragile. Protect it from collisions or other mechanical impacts. Crucially, never apply current without an electrolyte (dry burning), as this can cause irreversible damage to the electrode surface.

Making the Right Choice for Your Goal

A methodical inspection protocol is the foundation of trustworthy electrochemical data. Your level of rigor should match the demands of your work.

- If your primary focus is routine analysis: A thorough visual inspection for physical damage and surface cleanliness is the critical first step.

- If your primary focus is high-precision research: Augment the visual inspection with a functional verification test, such as a cyclic voltammogram in potassium ferricyanide, to confirm baseline performance before every critical experiment.

- If you are troubleshooting inconsistent results: Re-inspect the entire apparatus, including the holder and stand, as mechanical instability or poor connections are common and often-overlooked sources of error.

Ultimately, a few minutes spent on a careful pre-use inspection will save hours of questionable data and protect your valuable equipment.

Summary Table:

| Inspection Area | Key Checks | Why It Matters |

|---|---|---|

| Electrode Surface | Scratches, pits, deformation, cleanliness | Prevents inaccurate measurements and non-uniform current distribution |

| Support Apparatus | Secure holder connections, stable stand, smooth lifting mechanism | Ensures mechanical stability and eliminates electrical noise |

| Common Pitfalls | Cross-contamination, thermal/chemical damage, dry burning | Avoids irreversible surface damage and experiment failure |

Achieve consistent, high-quality electrochemical results with confidence. A meticulous pre-use inspection is your first step to reliable data. For researchers and laboratories demanding precision, the right equipment is paramount. KINTEK specializes in premium lab equipment and consumables, including electrochemical cells and accessories designed for durability and performance.

Let us support your research excellence. Contact our experts today to find the perfect solutions for your laboratory's specific needs.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements