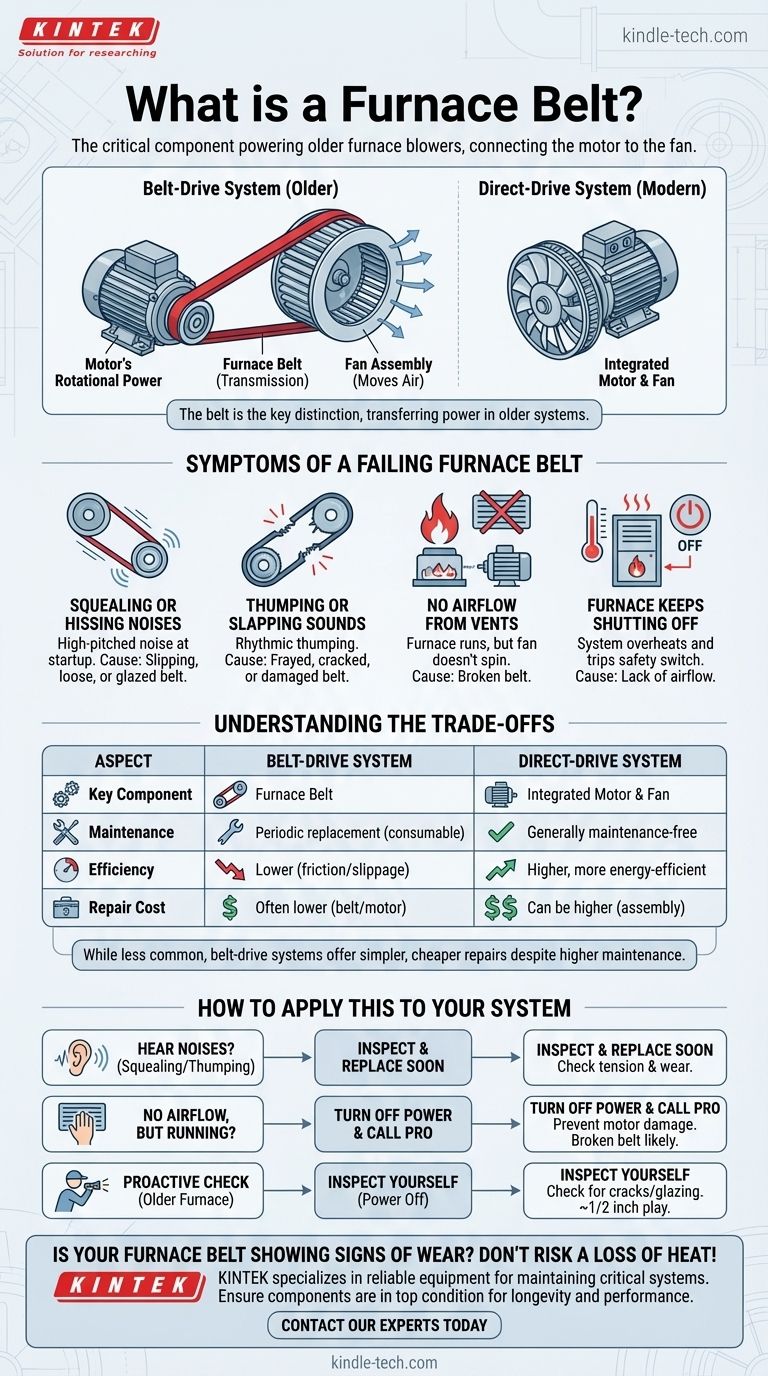

In short, a furnace belt is a critical component in older furnace models that connects the blower motor to the fan assembly. This heavy-duty rubber belt transfers the motor's rotational power to the fan, which is responsible for pushing heated air through your home's ductwork. If this belt fails, your furnace cannot circulate any air.

The existence of a furnace belt is the key distinction between an older belt-drive blower and a modern direct-drive system. While most new furnaces no longer use them, if your system has a belt, its condition is directly responsible for all airflow in your home.

The Role of the Furnace Belt

To understand the belt, you must first understand the blower system it powers. This system is the lungs of your HVAC, responsible for moving conditioned air.

The Blower's Job

Every furnace has a blower, which consists of a motor and a fan (often called a "squirrel cage"). Its sole purpose is to draw air into the furnace, push it across the heat exchanger to warm it up, and then distribute that warm air throughout your home.

The Belt as a "Transmission"

In a belt-drive system, the motor and the fan are two separate components. The furnace belt acts as the transmission, physically linking the motor's pulley to the fan's pulley.

When the furnace calls for heat, the motor spins its pulley. The belt grips this pulley and the fan's pulley, causing the fan to spin and move air. Without the belt, the motor would spin uselessly, and the fan would remain still.

The Rise of Direct-Drive Systems

Most modern furnaces use a direct-drive system. In this design, the fan is mounted directly onto the shaft of the motor. This eliminates the need for a belt and pulleys, resulting in a more efficient, quieter, and lower-maintenance design.

Identifying a Failing Furnace Belt

A furnace belt is a wearable part, like the tires on a car. It will eventually degrade and fail. Recognizing the warning signs can prevent a complete loss of heat.

Symptom 1: Squealing or Hissing Noises

A high-pitched squeal upon startup is the most common sign of a problem. This noise is caused by the belt slipping on the pulleys, which happens when the belt is loose, glazed over from age, or worn out.

Symptom 2: Thumping or Slapping Sounds

If you hear a rhythmic thumping or flapping sound coming from the blower cabinet, the belt is likely frayed, cracked, and on the verge of snapping completely. The noise is the damaged part of the belt hitting the housing as it rotates.

Symptom 3: No Airflow from Vents

This is the most definitive symptom. If you can hear the furnace burner ignite and the blower motor hum, but you feel no air coming from your vents, the belt has almost certainly broken. The system is trying to work, but the fan isn't spinning.

Symptom 4: The Furnace Keeps Shutting Off

A furnace that runs for a few minutes and then shuts down may be overheating. A broken belt prevents air from moving heat away from the heat exchanger, causing a safety device called the high-limit switch to trip and shut the system down to prevent damage.

Understanding the Trade-offs

While less common today, belt-drive systems have a distinct set of advantages and disadvantages you should be aware of.

The Downside: A Point of Failure

The belt is a consumable part. It is guaranteed to wear out and require replacement over its lifespan. This periodic maintenance is a drawback compared to maintenance-free direct-drive motors.

The Downside: Lower Efficiency

Friction and the potential for slippage mean that not all of the motor's energy is transferred to the fan. This makes belt-drive systems inherently less energy-efficient than their direct-drive counterparts.

The Upside: Simpler Repairs

While they require more maintenance, belt-drive systems can be easier and cheaper to repair. Replacing a worn-out belt or even a standalone motor is often much less expensive than replacing an entire integrated direct-drive motor and fan assembly.

How to Apply This to Your System

Your next step depends entirely on what your furnace is doing and your comfort level with basic inspection.

- If you hear squealing or thumping: This is a clear warning sign. The belt needs to be inspected for tension and wear, and likely replaced soon.

- If you have no airflow but the furnace is running: A broken belt is the most probable cause. Turn the system off at the thermostat and circuit breaker to prevent the motor from running without a load and call an HVAC professional for service.

- If you have an older furnace and want to be proactive: You can inspect the belt yourself. With the power off, check the belt for cracks, fraying, or a glazed, shiny surface. It should have about half an inch of "play" when pressed in the middle—not too tight and not too loose.

Knowing whether you have a belt-drive system gives you a powerful diagnostic advantage when troubleshooting your furnace.

Summary Table:

| Aspect | Belt-Drive System | Direct-Drive System |

|---|---|---|

| Key Component | Furnace Belt | Integrated Motor & Fan |

| Maintenance | Requires periodic belt replacement | Generally maintenance-free |

| Efficiency | Lower due to potential slippage | Higher, more energy-efficient |

| Repair Cost | Often lower (replace belt/motor) | Can be higher (replace entire assembly) |

Is your furnace belt showing signs of wear? Don't risk a loss of heat!

KINTEK specializes in providing reliable equipment and consumables for maintaining critical systems. For homeowners and HVAC professionals, ensuring your furnace components are in top condition is key to system longevity and performance.

Contact our experts today to discuss your needs and discover how KINTEK's solutions can help you maintain optimal performance and avoid costly downtime.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis