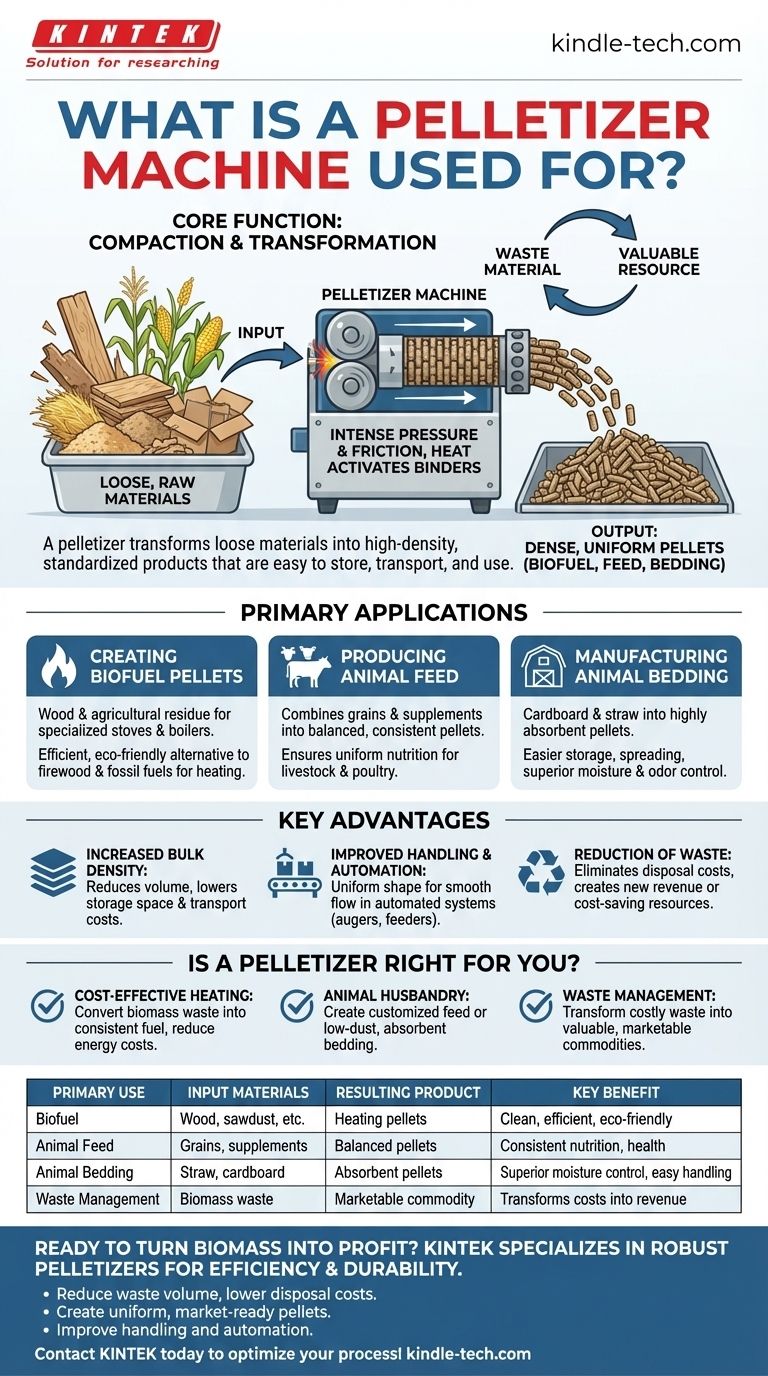

In essence, a pelletizer machine is a device that transforms loose, raw materials into dense, uniform pellets. It uses intense pressure to compact materials like wood scraps, sawdust, or agricultural byproducts into small, manageable cylinders for a variety of uses, most commonly for creating biofuel and animal feed.

The fundamental purpose of a pelletizer is to add value by converting low-density, difficult-to-handle waste or raw materials into a high-density, standardized product that is easy to store, transport, and use.

The Core Function: Compaction and Transformation

A pelletizer's value lies in its simple yet effective process. Understanding how it works clarifies its wide range of applications.

The Pelletizing Process

The machine feeds raw material into a chamber where it is compressed by rollers against a perforated metal plate called a die.

The immense pressure and friction force the material through the holes in the die, which forms the compact pellets. Heat generated during this compression process helps bind the material together, particularly with wood, by activating its natural lignin.

From Waste Material to Valuable Resource

A key strength of a pelletizer is its ability to process a wide variety of input materials. This makes it an exceptional tool for waste valorization.

Commonly used materials include wood waste (sawdust, shavings), agricultural residue (straw, corn stalks), and even cardboard.

Primary Applications of Pelletized Products

The dense, uniform nature of pellets makes them ideal for several key applications, turning a former waste stream into a consistent product.

Creating Biofuel Pellets

This is one of the most common uses. Wood pellets are a highly efficient and environmentally friendly fuel source for specialized pellet stoves and boilers.

Their uniform size and low moisture content allow for a controlled, clean burn, making them an excellent alternative to traditional firewood or fossil fuels for heating homes and businesses.

Producing Animal Feed

A pelletizer can be used to combine various grains and nutritional supplements into a single, balanced feed pellet.

This process ensures that livestock, poultry, and other animals consume a consistent diet in every bite, preventing them from selectively eating only their favorite ingredients.

Manufacturing Animal Bedding

Materials like cardboard or straw can be pelletized to create highly absorbent bedding for animal stalls.

These pellets are easier to store and spread than loose bedding, and their absorbent nature helps control moisture and odor more effectively.

Key Advantages of the Pelletizing Process

Transforming raw material into pellets provides several distinct operational and economic benefits.

Increased Bulk Density

Pellets are significantly denser than their source material. This dramatically reduces the volume required for storage and makes transportation far more cost-effective.

Improved Handling and Automation

The uniform shape and size of pellets allow them to flow smoothly. This makes them perfectly suited for use in automated systems, such as pellet stove augers or automated animal feeders.

Reduction of Waste

By converting waste materials into a useful product, a pelletizer can eliminate disposal costs and create a new revenue stream or cost-saving resource.

How to Determine if a Pelletizer is Right for You

Choosing to invest in this technology depends entirely on your primary goal and the raw materials you have available.

- If your primary focus is cost-effective heating: A pelletizer allows you to convert available biomass waste into a consistent, eco-friendly fuel source, potentially reducing your energy costs.

- If your primary focus is animal husbandry: The machine enables you to create customized, nutritionally complete feed or produce low-dust, highly absorbent bedding for your animals.

- If your primary focus is waste management: A pelletizer provides a direct path to transform costly waste disposal into the creation of a valuable, marketable commodity.

Ultimately, a pelletizer is a powerful tool for converting underutilized resources into consistent, valuable, and manageable products.

Summary Table:

| Primary Use | Input Materials | Resulting Product | Key Benefit |

|---|---|---|---|

| Biofuel Production | Wood scraps, sawdust, agricultural residue | High-density heating pellets | Clean, efficient, and eco-friendly fuel source |

| Animal Feed | Grains, nutritional supplements | Balanced feed pellets | Consistent nutrition and improved animal health |

| Animal Bedding | Straw, cardboard | Highly absorbent bedding pellets | Superior moisture control and easier handling |

| Waste Management | Various biomass waste | Marketable commodity | Transforms disposal costs into a revenue stream |

Ready to turn your biomass or raw materials into a profitable, high-density product?

KINTEK specializes in robust laboratory and industrial equipment, including pelletizers designed for efficiency and durability. Whether you're in biofuel production, animal husbandry, or waste management, our solutions help you:

- Reduce waste volume and lower disposal costs.

- Create uniform, market-ready pellets for fuel, feed, or bedding.

- Improve handling and automation with consistent, flowable products.

Let our experts help you select the right pelletizer for your specific material and output goals. Contact KINTEK today to discuss your project and discover how our lab equipment can optimize your process!

Visual Guide

Related Products

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Touchscreen Automatic Vacuum Heat Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material

- What is a tablet punching machine called? Choosing the Right Press for Your Production Scale

- What is a pellet mill? Transform Powder into High-Density Pellets Efficiently

- Are wood pellets made from sawdust? Unlock the Secret to High-Performance Fuel

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- How does a flat die pellet mill work? A Complete Guide to Small-Scale Pellet Production

- What are the different parts of a single punch tablet machine? The Core Components Explained