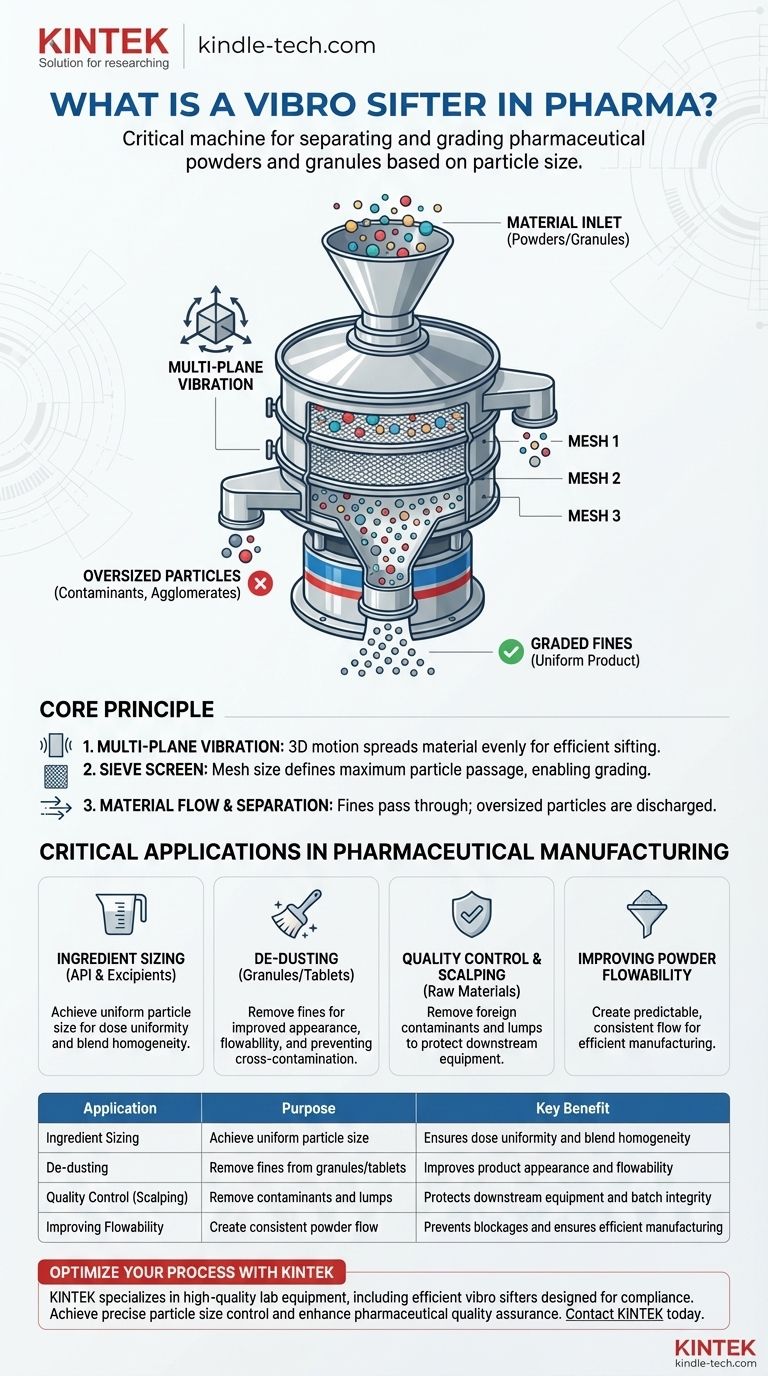

In the pharmaceutical industry, a vibro sifter is a critical machine used for the separation and grading of powders and granules based on their particle size. It functions as a high-precision sieve, utilizing multi-plane vibrations to efficiently sort materials. This process is essential for ensuring the quality, safety, and efficacy of the final medicinal product by guaranteeing ingredient uniformity and removing contaminants.

At its core, the vibro sifter is not merely a separator but a fundamental quality control instrument. Its primary purpose is to enforce particle size consistency, which directly impacts everything from the drug's absorption rate in the body to the uniformity of dosage in each tablet.

The Core Principle: How a Vibro Sifter Works

A vibro sifter's effectiveness comes from a simple yet precisely engineered mechanical process. Understanding this mechanism clarifies its role in manufacturing.

Multi-Plane Vibration

The machine is driven by a specially designed unbalanced motor positioned underneath the screen assembly. This motor creates a unique three-dimensional vibratory motion—simultaneously horizontal, vertical, and inclinational. This complex movement ensures material spreads evenly across the entire surface of the screen, maximizing the sifting efficiency.

The Role of the Sieve Screen

The heart of the sifter is the sieve screen, a mesh of a specific size. Screens are classified by their mesh number (wires per inch) or in microns, which defines the maximum particle size that can pass through. Pharmaceutical applications often use multiple stacked screens to separate a material into several different size grades in a single pass.

Material Flow and Separation

As the material is fed onto the top screen, the vibration causes a stratification effect. Finer particles quickly work their way down and pass through the mesh openings. Larger, oversized particles are unable to pass through and are carried by the vibration towards an outlet port on the screen's periphery, effectively separating the material into different fractions.

Critical Applications in Pharmaceutical Manufacturing

The vibro sifter is not a standalone device but an integral part of several key stages in the pharmaceutical production line.

Ensuring Ingredient Uniformity (Sizing)

The Active Pharmaceutical Ingredient (API) and various excipients (fillers, binders) must have a consistent and compatible particle size distribution. If particle sizes vary too widely, smaller particles can segregate from larger ones during handling, a phenomenon known as "demixing." Sifting ensures all ingredients can be blended into a homogenous mixture, which is crucial for dose uniformity.

De-dusting and Fines Removal

After processes like granulation or tablet compression, fine dust can adhere to the final product. A vibro sifter is used to gently tumble and screen the granules or tablets, removing this unwanted dust. This improves the product's appearance, prevents issues in packaging, and reduces the risk of cross-contamination in the facility.

Quality Control and Screening (Scalping)

Vibro sifters are often used as the first line of defense when raw materials arrive. This process, known as scalping or check-screening, removes any foreign contaminants, packaging debris, or large, hardened lumps (agglomerates) before they can enter the manufacturing stream and damage downstream equipment or compromise the batch.

Improving Powder Flowability

Powders with a uniform particle size distribution flow more predictably and consistently from hoppers into tablet presses and capsule fillers. Sifting removes oversized particles that can cause blockages and fines that can impede flow, ensuring a smooth and efficient manufacturing run.

Understanding the Trade-offs and Considerations

While essential, implementing a vibro sifter requires careful process control to avoid potential issues.

Choosing the Right Mesh Size

Selecting the correct screen mesh is a critical parameter that must be validated for each product. A mesh that is too fine can significantly slow down the process or become blocked (blinding). A mesh that is too coarse will fail to provide adequate separation, compromising product quality.

Managing Material Attrition

The very vibration that makes the sifter effective can sometimes be too aggressive for delicate granules. This can cause the material to break down (attrition), creating more fines and altering the particle size distribution. The sifter’s motor can be adjusted to control the vibration amplitude and prevent this.

Cleaning and Cross-Contamination Risk

Like all pharmaceutical equipment, vibro sifters must be designed for easy and thorough cleaning. They are typically constructed from high-grade stainless steel (SS 316L) with smooth, polished surfaces. Inadequate cleaning between different product batches poses a serious risk of cross-contamination.

Making the Right Choice for Your Process

The specific use of a vibro sifter depends entirely on the manufacturing goal at that particular stage.

- If your primary focus is raw material integrity: Use a single-deck sifter for check-screening to remove foreign matter and lumps before materials enter inventory.

- If your primary focus is achieving dose uniformity: Employ a multi-deck sifter after milling or granulation to achieve a narrow and consistent particle size distribution before blending.

- If your primary focus is final product quality: Implement a gentle sifting process for de-dusting tablets or capsules just before coating or packaging.

Ultimately, the vibro sifter serves as a guardian of consistency, ensuring that every dose of a medicine is as safe and effective as the next.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ingredient Sizing | Achieve uniform particle size | Ensures dose uniformity and blend homogeneity |

| De-dusting | Remove fines from granules/tablets | Improves product appearance and flowability |

| Quality Control (Scalping) | Remove contaminants and lumps | Protects downstream equipment and batch integrity |

| Improving Flowability | Create consistent powder flow | Prevents blockages and ensures efficient manufacturing |

Achieve precise particle size control and enhance your pharmaceutical quality assurance. KINTEK specializes in high-quality lab equipment and consumables for the pharmaceutical industry. Our vibro sifters are designed for efficiency, easy cleaning, and compliance with stringent industry standards. Let our experts help you select the perfect equipment for your specific application—from raw material screening to final product de-dusting. Contact KINTEK today to optimize your process and safeguard your product quality!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- Why is sieve test important? Ensure Product Quality and Performance with Precise Particle Analysis

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- How do you maintain a sieve shaker? Ensure Accurate Particle Size Analysis Every Time

- What are the principles of a sieve shaker? Achieve Accurate Particle Size Analysis

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis