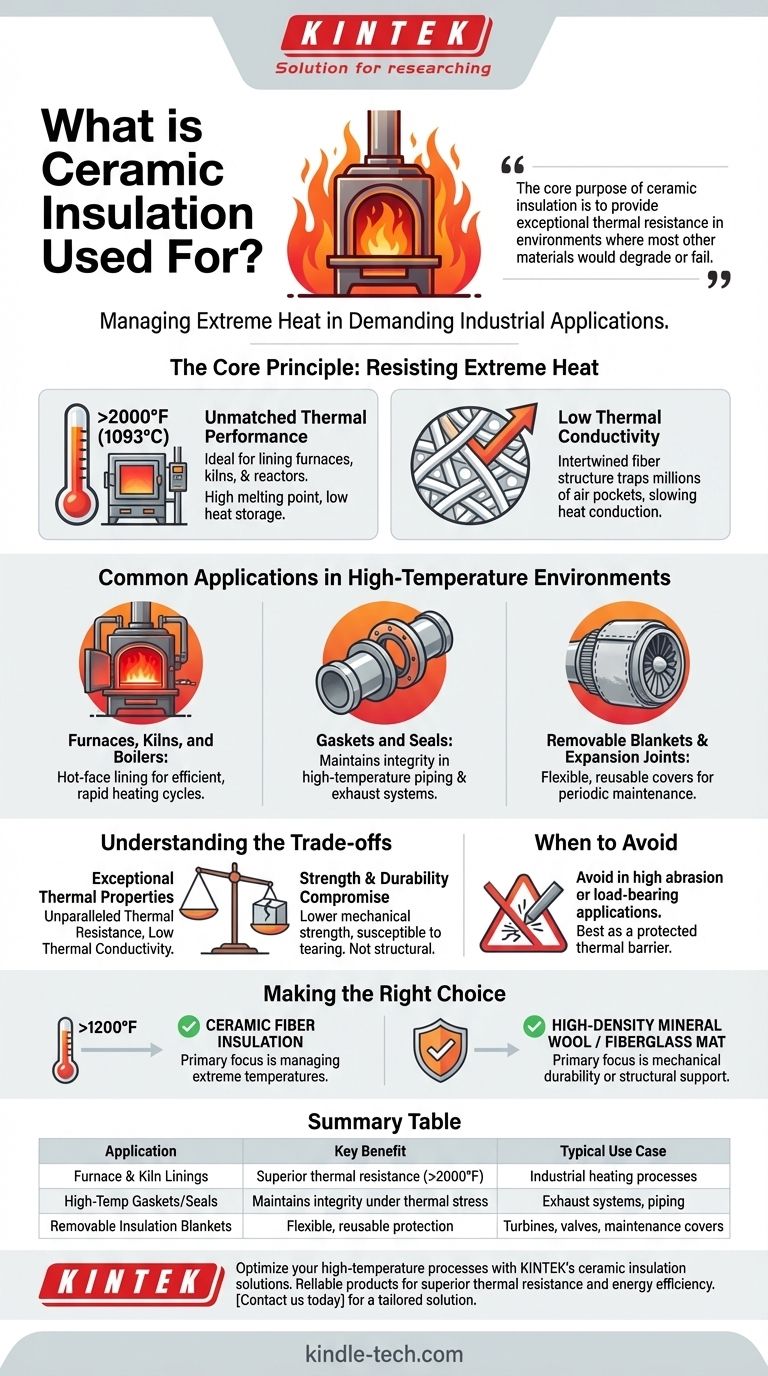

In essence, ceramic insulation is used in demanding, high-temperature industrial applications where managing extreme heat is the primary goal. Common uses include furnace maintenance, high-temperature gaskets and seals, fabric expansion joints, and removable industrial insulation blankets.

The core purpose of ceramic insulation is to provide exceptional thermal resistance in environments where most other materials would degrade or fail. It is chosen specifically for its ability to handle extreme heat, even at the expense of mechanical strength and durability.

The Core Principle: Resisting Extreme Heat

Ceramic insulation excels in one critical area: withstanding incredibly high temperatures. This singular focus defines its composition, function, and ideal applications.

Unmatched Thermal Performance

The defining characteristic of ceramic fiber is its very high melting point and low heat storage. This makes it ideal for lining furnaces, kilns, and reactors where temperatures can exceed 2000°F (1093°C).

Low Thermal Conductivity

This material is composed of a mass of intertwined ceramic fibers. This structure traps millions of tiny air pockets, which dramatically slows the transfer of heat through conduction and convection, making it a highly effective insulator.

Common Applications in High-Temperature Environments

The unique properties of ceramic insulation make it the go-to solution for very specific industrial challenges.

Furnaces, Kilns, and Boilers

Ceramic insulation is frequently used as a hot-face lining in industrial furnaces. Its light weight and high-temperature resistance allow for more efficient and rapid heating and cooling cycles compared to traditional dense refractory bricks.

Gaskets and Seals

In high-temperature piping, exhaust systems, or machinery, a reliable seal is needed that won't burn or degrade. Ceramic fiber can be formed into gaskets and seals that maintain their integrity under intense thermal stress.

Removable Blankets and Expansion Joints

For equipment that requires periodic maintenance, such as turbines or valves, removable insulation blankets are essential. Ceramic fiber's flexibility and heat resistance make it the perfect material for these custom-fitted, reusable covers.

Understanding the Trade-offs

While its thermal properties are exceptional, ceramic insulation is not a universal solution. Its limitations are as important to understand as its strengths.

The Strength and Durability Compromise

Ceramic fiber insulation is not a structural material. Compared to alternatives like glass mat or mineral wool, it has lower mechanical strength and is more susceptible to tearing or physical damage.

When to Avoid Ceramic Insulation

This material should not be used in applications requiring high abrasion resistance or where it would be subjected to direct physical impact or load-bearing stress. It serves best as a protected thermal barrier, not a durable structural component.

Making the Right Choice for Your Application

Choosing the correct insulation requires matching the material's properties to your primary goal.

- If your primary focus is managing extreme temperatures (above 1200°F / 650°C): Ceramic fiber is the superior choice due to its unparalleled thermal resistance.

- If your primary focus is mechanical durability, moisture resistance, or structural support: A material like high-density mineral wool or fiberglass mat will be a more robust and appropriate solution.

Ultimately, selecting ceramic insulation is a deliberate decision to prioritize superior heat management over raw mechanical strength.

Summary Table:

| Application | Key Benefit | Typical Use Case |

|---|---|---|

| Furnace & Kiln Linings | Superior thermal resistance (>2000°F) | Industrial heating processes |

| High-Temp Gaskets/Seals | Maintains integrity under thermal stress | Exhaust systems, piping |

| Removable Insulation Blankets | Flexible, reusable protection | Turbines, valves, maintenance covers |

Optimize your high-temperature processes with KINTEK's ceramic insulation solutions.

As a specialist in lab equipment and consumables, KINTEK provides reliable ceramic insulation products designed for extreme heat management in furnaces, kilns, and industrial systems. Our expertise ensures you get the right material for superior thermal resistance and energy efficiency.

Contact us today to discuss your specific application and receive a tailored solution that enhances safety and performance in your laboratory or industrial setting.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- How much pressure can silica glass withstand? Design for Strength Beyond the Theoretical Limit

- Why is an industrial-grade ultrasonic cleaner required for LDH conversion? Ensure Pure Crystal Growth & Adhesion

- Why is a multi-position magnetic stirrer necessary for dye degradation? Ensure Uniformity in Photocatalytic Experiments

- How can a gas ballast valve be used as a diagnostic tool? Identify Oil Contamination vs. System Leaks

- What are the advantages of refractory materials? Ensure Efficiency and Safety in High-Temperature Processes

- Why are high-temperature resistant springs used for Tantalum wire in HFCVD? Achieve Precise Diamond Film Uniformity

- What size is a quartz tube? Custom Dimensions for Your Lab's Furnace & Process Needs

- What role does an ultrasonic cleaner play in the pretreatment of titanium alloy samples for biological testing?