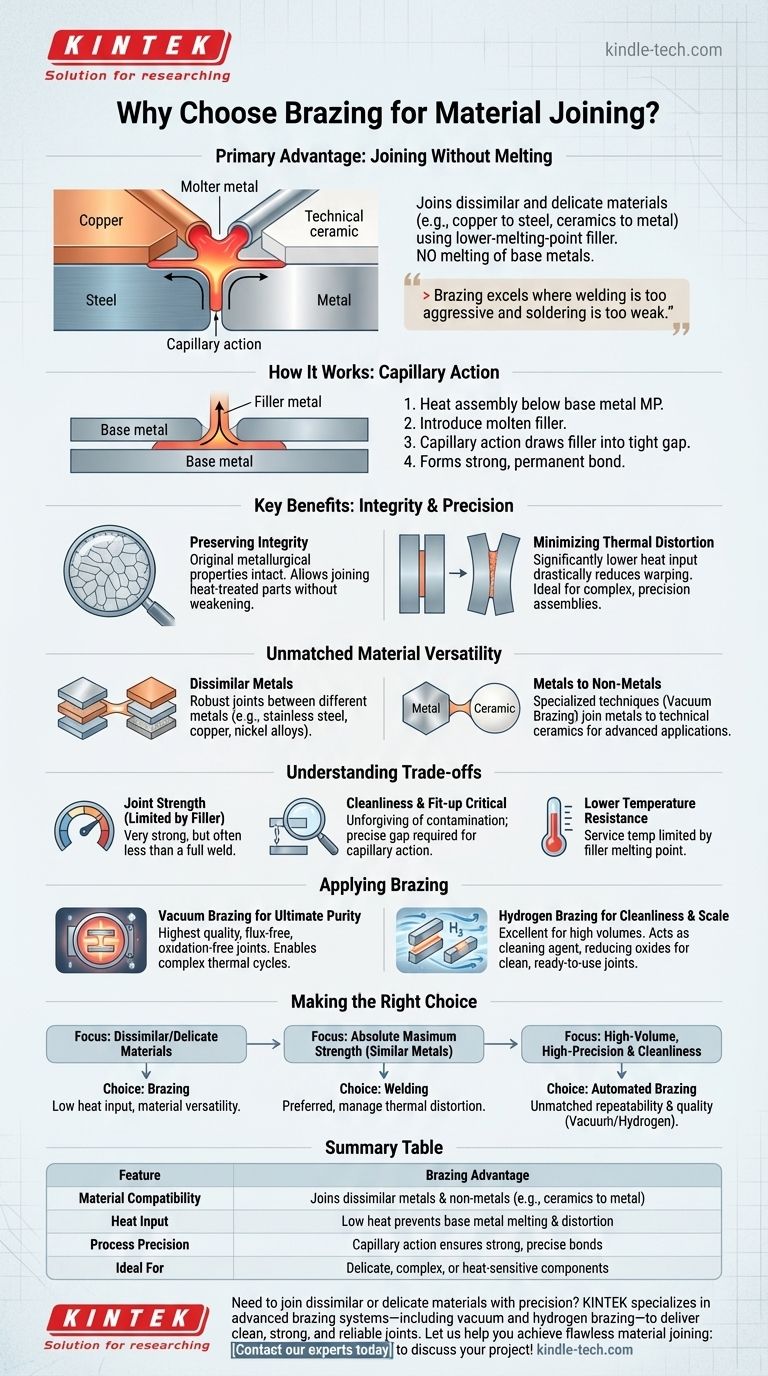

A primary advantage of brazing is its unique ability to join dissimilar materials—such as copper to steel, or even ceramics to metal—without melting the base materials. This is accomplished by heating the components and introducing a filler metal that melts at a lower temperature, which is then drawn into the tight-fitting joint by capillary action to form a strong, permanent bond.

Brazing excels in applications where welding is too aggressive and soldering is too weak. Its core strength lies in joining delicate, complex, or dissimilar materials with high precision and minimal distortion, a feat achieved by using a filler metal that bonds the parts without melting them.

The Core Principle: Joining Without Melting

Brazing is fundamentally different from welding. Instead of fusing the parent materials together, it acts more like a metallurgical "glue," creating a powerful bond while preserving the integrity of the components being joined.

How Brazing Works

The process relies on a principle called capillary action. A small, precise gap is designed between the two parts. When the assembly is heated to the melting point of the filler metal (but below that of the base metals), the molten filler is automatically drawn into that gap, filling it completely.

Preserving Material Integrity

Because the base metals are never melted, their original metallurgical properties remain intact. This allows for the joining of heat-treated or work-hardened components without weakening them, and enables engineers to design parts with very close dimensional tolerances.

Minimizing Thermal Distortion

Compared to welding, brazing uses significantly lower overall temperatures. This lower heat input drastically reduces the risk of thermal distortion and warping, making it the ideal choice for complex, delicate, or high-precision assemblies where maintaining the final shape is critical.

Unmatched Material Versatility

The fact that the base metals are not melted unlocks a range of design possibilities that are difficult or impossible to achieve with other methods.

Joining Dissimilar Metals

Welding dissimilar metals is often a complex metallurgical challenge, as they must be compatible to form a solid fused joint. Brazing bypasses this issue entirely, allowing for robust joints between materials like stainless steel, copper, nickel alloys, and more.

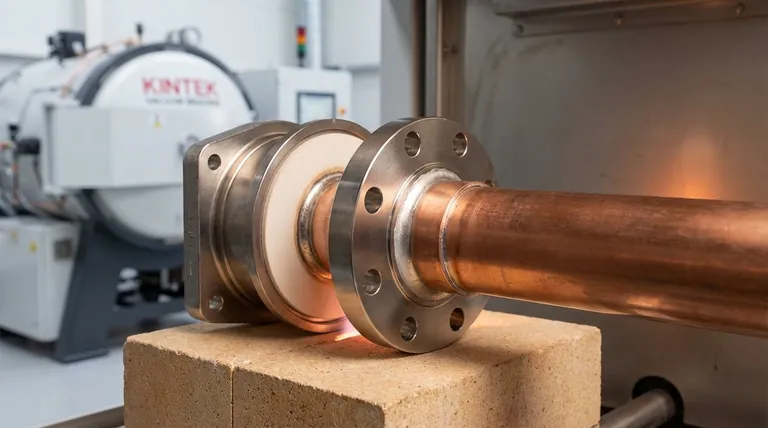

Bonding Metals to Non-Metals

Specialized brazing techniques, particularly vacuum brazing, make it possible to join metals to non-metallic materials like technical ceramics. This capability is essential for producing advanced components used in the aerospace, medical, and electronics industries.

Understanding the Trade-offs

No process is perfect for every situation. To make an informed decision, you must understand the limitations of brazing.

Joint Strength is Limited by the Filler

A brazed joint's strength is determined by the filler metal used and the integrity of the bond. While very strong, it typically does not match the ultimate strength of a properly executed weld that has fused the base metals themselves.

Cleanliness and Fit-up are Critical

Brazing is unforgiving of contamination. The surfaces of the base metals must be exceptionally clean for the filler metal to wet the surfaces and for capillary action to work. Likewise, the gap between the parts must be controlled precisely—too wide and capillary action fails, too narrow and the filler cannot flow in.

Lower Temperature Resistance Than a Weld

The service temperature of a brazed component is limited by the melting point of the filler alloy. In high-temperature applications, a welded joint will almost always offer superior performance.

Applying Brazing to Your Project

The specific method of brazing—from simple torch brazing to advanced, automated processes—can be selected to meet project goals for quality, purity, and volume.

Vacuum Brazing for Ultimate Purity

For mission-critical applications, vacuum brazing provides the highest quality. By performing the process in a vacuum, it produces exceptionally clean, flux-free joints without oxidation. This method also allows for complex thermal cycles, enabling hardening or annealing of the part in the same process, saving significant time and cost.

Hydrogen Brazing for Cleanliness and Scale

When clean, aesthetically pleasing parts are needed in high volumes, hydrogen brazing is an excellent choice. The hydrogen atmosphere acts as a cleaning agent, reducing surface oxides and ensuring a strong, pure joint that is ready for use with minimal post-processing.

Making the Right Choice for Your Goal

Selecting the correct joining process requires aligning its capabilities with your primary objective.

- If your primary focus is joining dissimilar materials or delicate components: Brazing is the superior choice due to its low heat input and material versatility.

- If your primary focus is achieving the absolute maximum joint strength for similar metals: Welding is generally the preferred method, provided you can manage the resulting thermal distortion.

- If your primary focus is high-volume, high-precision assembly with exceptional cleanliness: Automated processes like vacuum or hydrogen brazing offer unmatched repeatability and quality.

Understanding these fundamental differences empowers you to select the joining process that best serves your specific engineering requirements.

Summary Table:

| Feature | Brazing Advantage |

|---|---|

| Material Compatibility | Joins dissimilar metals & non-metals (e.g., ceramics to metal) |

| Heat Input | Low heat prevents base metal melting & distortion |

| Process Precision | Capillary action ensures strong, precise bonds |

| Ideal For | Delicate, complex, or heat-sensitive components |

Need to join dissimilar or delicate materials with precision?

Brazing offers a superior solution for complex assemblies where welding is too aggressive and soldering is too weak. At KINTEK, we specialize in advanced brazing systems—including vacuum and hydrogen brazing—to deliver clean, strong, and reliable joints for your laboratory and industrial equipment.

Let us help you achieve flawless material joining:

Contact our experts today to discuss your project requirements and discover the ideal brazing solution for your needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance