At its core, Physical Vapor Deposition (PVD) is a vacuum-based coating process that applies an exceptionally thin, high-performance film onto a substrate. The process works by turning a solid source material into a vapor, which then travels through the vacuum and condenses onto the target object, building the coating atom by atom. This method is purely physical; no chemical reactions take place.

PVD is not simply a coating method; it is a form of surface engineering. It allows you to fundamentally upgrade the surface properties of a material—like hardness, wear resistance, or conductivity—without altering the core properties of the underlying object.

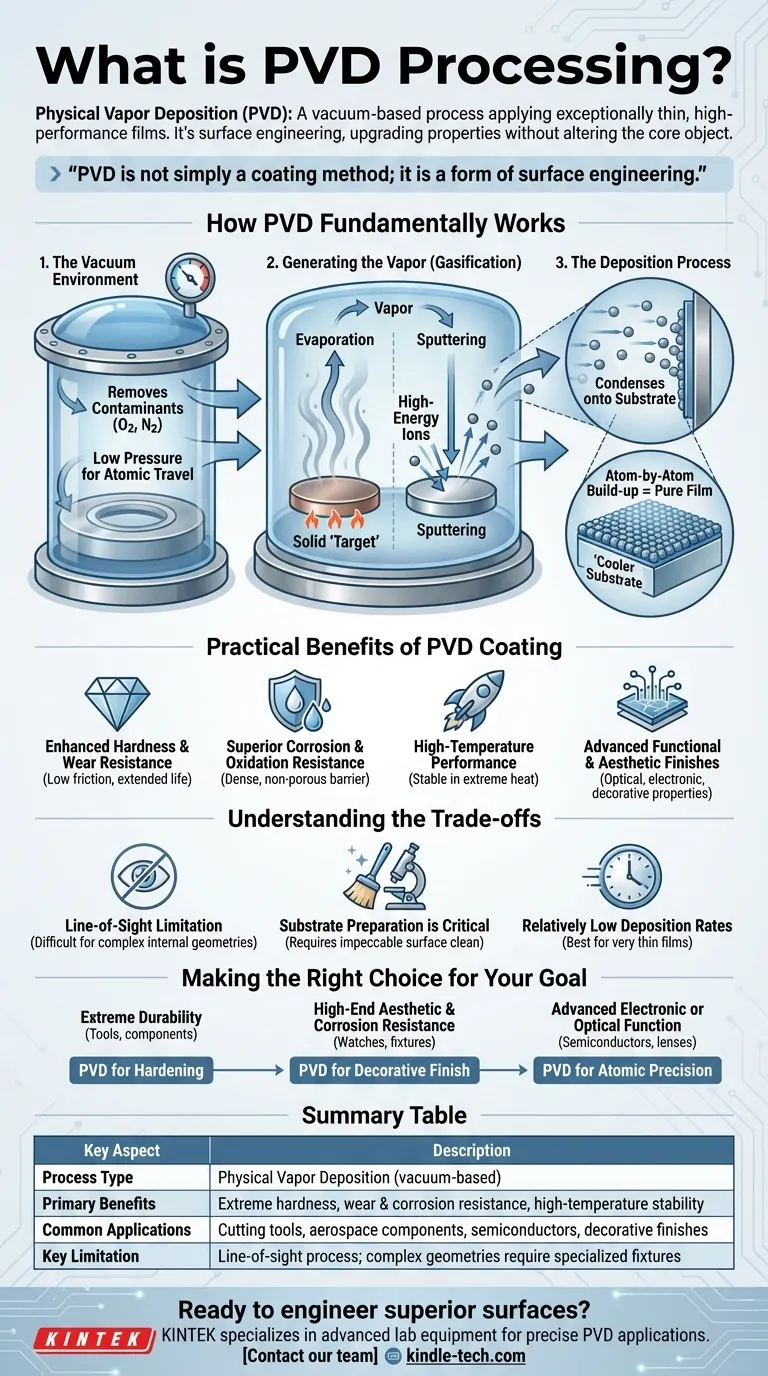

How PVD Fundamentally Works

The PVD process can be broken down into three critical stages, all of which occur under a precisely controlled high vacuum.

The Vacuum Environment

The entire process takes place inside a vacuum chamber at very low pressure. This is essential to remove atmospheric contaminants like oxygen and nitrogen, which would otherwise interfere with the coating. The vacuum also allows vaporized atoms to travel directly to the substrate without colliding with air molecules.

Generating the Vapor (Gasification)

A solid, pure source material, known as the target, is converted into a vapor. This is typically achieved through one of two primary methods:

- Evaporation: The target material is heated until it evaporates into a gas.

- Sputtering: The target is bombarded with high-energy ions (often from an inert gas like Argon), which physically knock atoms off the target's surface.

The Deposition Process

The vaporized material travels through the vacuum chamber and condenses onto the cooler substrate (the object being coated). Because this happens on an atomic level, the resulting film is extremely dense, pure, and tightly bonded to the surface. It precisely replicates the object's original surface finish, often requiring no post-polishing.

The Practical Benefits of a PVD Coating

The true value of PVD is in the functional properties it imparts to a surface. These coatings solve specific engineering and design challenges.

Enhanced Hardness and Wear Resistance

PVD coatings are exceptionally hard and have a low coefficient of friction. This makes them ideal for cutting tools, engine components, and other parts subject to intense wear, dramatically extending their service life.

Superior Corrosion and Oxidation Resistance

The deposited film is incredibly dense and non-porous, creating a robust barrier that protects the substrate from oxidation and chemical attack. This is critical for components used in harsh environments.

High-Temperature Performance

Many PVD coatings are highly stable at elevated temperatures. This makes them essential for applications in the aerospace industry, where components must resist extreme heat and ablation.

Advanced Functional and Aesthetic Finishes

PVD is used to create thin films with specific optical or electronic properties, vital for semiconductors, thin-film solar panels, and specialized glass. It is also used for durable, high-end decorative finishes on consumer products where both appearance and longevity are paramount.

Understanding the Trade-offs

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

Line-of-Sight Limitation

The vaporized coating material travels in a straight line from the source to the substrate. This makes it very difficult to uniformly coat complex internal geometries or the undersides of intricate parts without complex fixtures and rotation.

Substrate Preparation is Critical

The performance of a PVD coating is highly dependent on the condition of the surface it is applied to. The substrate must be impeccably clean and free of any contaminants, as the thin film will replicate any surface imperfections.

Relatively Low Deposition Rates

Compared to processes like electroplating, PVD is generally a slower method for building up material thickness. It is optimized for producing very thin films (typically a few microns), not for creating thick, bulk coatings.

Making the Right Choice for Your Goal

PVD is a specialized process chosen to solve a specific problem. Your decision to use it should be based on your primary objective.

- If your primary focus is extreme durability and wear resistance: PVD is a leading choice for hardening the surfaces of tools, molds, and mechanical components to extend their operational life.

- If your primary focus is a high-end aesthetic with corrosion resistance: PVD offers a superior and long-lasting decorative finish for items like watches, architectural hardware, and plumbing fixtures.

- If your primary focus is advanced electronic or optical function: PVD provides the atomic-level precision required for manufacturing semiconductors, sensors, and specialized optical lenses.

Ultimately, PVD is a key enabling technology for creating modern, high-performance products by precisely engineering their surfaces.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (vacuum-based) |

| Primary Benefits | Extreme hardness, wear & corrosion resistance, high-temperature stability |

| Common Applications | Cutting tools, aerospace components, semiconductors, decorative finishes |

| Key Limitation | Line-of-sight process; complex geometries require specialized fixtures |

Ready to engineer superior surfaces for your products?

PVD processing is a powerful solution for enhancing durability, performance, and aesthetics. The experts at KINTEK specialize in providing the advanced lab equipment and consumables necessary for precise PVD applications. Whether you are developing cutting tools, aerospace components, or high-end consumer goods, we can help you achieve the perfect coating.

Contact our team today to discuss how our solutions can meet your specific laboratory and production needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition