At its core, Physical Vapor Deposition (PVD) is a vacuum-based process that creates an ultra-thin, high-performance coating on an object. The technique works by turning a solid source material into a vapor within a high vacuum chamber and then allowing that vapor to condense, atom by atom, onto the surface of the part being coated. This results in a thin, bonded, and extremely durable layer that enhances the part's physical properties.

PVD is not a wet paint or plating process; it's a dry, physical transformation occurring in a vacuum. It transfers material from a source to a target without chemical reactions, fundamentally enhancing the surface properties of an object like its hardness, wear resistance, or appearance.

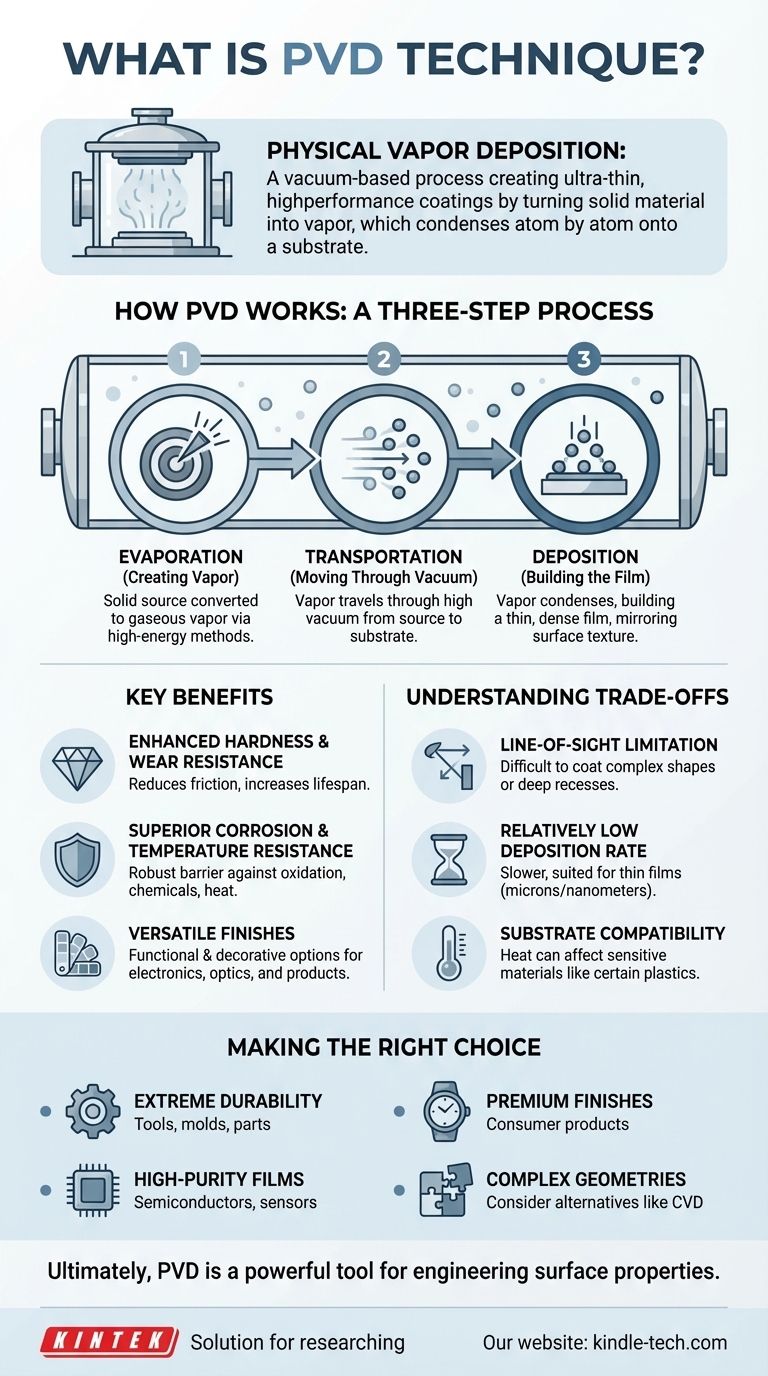

How PVD Works: A Three-Step Process

The entire PVD process occurs under a very high vacuum (very low pressure) to ensure purity and prevent unwanted reactions with air. It can be broken down into three fundamental stages.

Step 1: Evaporation (Creating the Vapor)

First, a solid, pure source material—often called the "target"—is converted into a gaseous vapor. This is achieved using high-energy methods like high-temperature evaporation or by bombarding the target with high-energy ions, a process known as sputtering.

Step 2: Transportation (Moving Through the Vacuum)

The vaporized atoms or molecules travel through the vacuum chamber from the source material toward the substrate (the object to be coated). The vacuum environment is critical, as it provides a clear, contaminant-free path for the vapor to travel.

Step 3: Deposition (Building the Film)

When the vaporized material reaches the substrate, it condenses back into a solid state. This condensation builds up in a controlled, atom-by-atom manner, forming a thin, dense, and highly adherent film on the substrate's surface. Because this is a physical process, the resulting coating mirrors the original surface texture, often producing a brilliant finish without needing to be polished.

Key Benefits of PVD Coatings

The atomic bonding process gives PVD coatings unique characteristics that are superior to many traditional coating methods.

Enhanced Hardness and Wear Resistance

PVD coatings are exceptionally hard and dense. This makes them ideal for reducing friction on moving parts and dramatically increasing the lifespan of items like cutting tools and industrial molds.

Superior Corrosion and Temperature Resistance

The deposited film acts as a robust barrier against the environment. This provides excellent protection from oxidation (rust), chemical attack, and degradation from high temperatures, which is critical in aerospace and automotive applications.

Versatile Functional and Decorative Finishes

PVD can deposit a wide range of materials, including metals, non-metals, and compounds. This allows for the creation of coatings that serve specific electronic or optical functions, such as in semiconductors and solar panels, as well as durable and attractive decorative finishes.

Understanding the Trade-offs

While powerful, PVD is not the solution for every application. Understanding its limitations is key to using it effectively.

Line-of-Sight Limitation

PVD is a "line-of-sight" process. The vaporized material travels in a straight line, which means it can be difficult to uniformly coat complex shapes with deep recesses or internal channels that are not directly exposed to the vapor source.

Relatively Low Deposition Rate

Building a film atom by atom is precise but can be slower than other bulk coating methods like electroplating. PVD is therefore best suited for creating very thin films, typically measured in microns or nanometers.

Substrate Compatibility

Although PVD is considered a low-temperature process compared to melting points, the chamber can still reach several hundred degrees. This can make it unsuitable for coating heat-sensitive materials like certain plastics without careful process control.

Making the Right Choice for Your Goal

PVD is a highly specialized technique. Your decision to use it should be based on your primary objective.

- If your primary focus is extreme durability and wear resistance: PVD is an exceptional choice for hardening the surfaces of cutting tools, engine parts, or industrial molds.

- If your primary focus is a high-purity electronic or optical film: The high-vacuum, clean nature of PVD makes it ideal for manufacturing semiconductors, sensors, and specialized glass coatings.

- If your primary focus is a premium, long-lasting decorative finish: PVD provides a superior, environmentally cleaner alternative to traditional plating for achieving durable colors and metallic sheens on consumer products.

- If your primary focus is coating complex, internal geometries: You may need to investigate alternative methods like Chemical Vapor Deposition (CVD), which uses a gas that can penetrate and coat non-line-of-sight surfaces.

Ultimately, PVD is a powerful tool for engineering the surface of a material to give it properties it otherwise would not possess.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Vacuum-based, dry physical process (not chemical plating) |

| Key Steps | Evaporation, Transportation, Deposition |

| Primary Benefits | Extreme hardness, superior wear/corrosion resistance, versatile finishes |

| Common Applications | Cutting tools, industrial molds, semiconductors, decorative finishes |

| Main Limitation | Line-of-sight coating (difficult for complex internal geometries) |

Ready to enhance your products with a high-performance PVD coating?

KINTEK specializes in advanced lab equipment and consumables for surface engineering. Whether you are developing durable tools, high-purity electronic components, or premium decorative finishes, our expertise and solutions can help you achieve superior results.

Contact our experts today to discuss how PVD technology can solve your specific coating challenges and add value to your laboratory or production line.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition