In the context of material processing, rolling pressure is the intense compressive stress exerted by rollers onto a workpiece to permanently deform it and reduce its thickness. While rooted in the basic formula of Pressure = Force / Area, the term specifically refers to the complex and non-uniform pressure distribution that occurs within the contact zone between the roller and the material, known as the "roll bite."

The critical takeaway is that "rolling pressure" is not a single, static value. It is a dynamic pressure gradient that peaks at a specific "neutral point," and mastering control over this pressure distribution is essential for achieving desired material properties and avoiding defects in manufacturing.

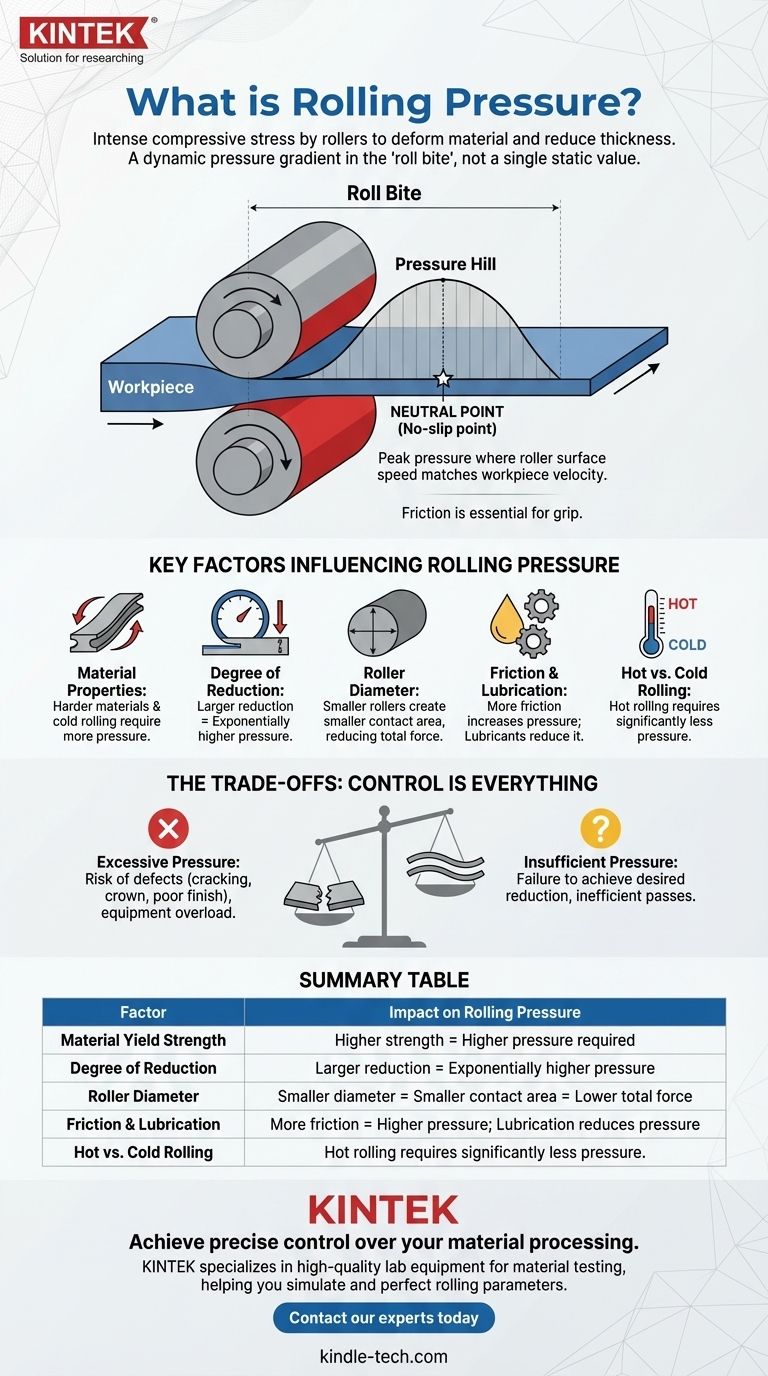

Deconstructing the "Roll Bite": The Heart of the Process

The concept of rolling pressure is meaningless without first understanding the "roll bite." This is the small, arc-shaped area where the rollers are in direct contact with the workpiece, actively compressing it.

The Force vs. The Pressure

In practice, engineers often focus on rolling force, which is the total force (F) applied by the mill stand. Rolling pressure (P) is how that total force is distributed over the contact area (A) of the roll bite.

Because the contact area is curved and material is flowing, this pressure is not uniform. It forms a distinct "pressure hill" when plotted across the contact length.

The Pressure Distribution Curve

Imagine a graph of the pressure along the roll bite. It starts low as the material enters, rises sharply to a peak, and then falls again as the material exits. This shape is the "pressure hill."

The existence of this hill is fundamental. It shows that some parts of the workpiece are under significantly more stress than others during the rolling process.

The Neutral Point: A Point of No Slip

The peak of the pressure hill occurs at a location called the neutral point or no-slip point.

At this specific point, the surface speed of the roller perfectly matches the forward velocity of the workpiece. Before this point, the rollers are moving faster than the material, pulling it in. After this point, the material is moving faster than the rollers, pushing its way out.

Friction's Necessary Role

Friction is what allows the rollers to grip the workpiece and pull it into the roll bite. Without friction, the rollers would simply slip against the surface.

However, this same friction also increases the total force and energy required for deformation, contributing significantly to the magnitude of the rolling pressure.

Key Factors That Influence Rolling Pressure

Controlling rolling pressure requires managing a set of interconnected variables. A change in one will impact all the others.

Material Properties

The material's yield strength and work-hardening characteristics are the primary drivers. Harder materials require more pressure to deform. This is why hot rolling (above the material's recrystallization temperature) requires significantly less pressure than cold rolling.

The Degree of Reduction

The amount of thickness change in a single pass, known as reduction, has a major impact. Attempting a larger reduction demands exponentially higher force and results in a greater peak rolling pressure.

Roller Geometry

The diameter of the rollers is critical. Smaller diameter rollers create a smaller contact area, which can reduce the total rolling force required. However, they are also more prone to deflection, which can affect the final product's dimensional accuracy.

Process Parameters

Variables like rolling speed and the use of lubricants directly affect the friction in the roll bite. Lubricants are used to reduce friction, lowering the required force and preventing surface defects, but a certain amount of friction is still needed to pull the material through.

Understanding the Trade-offs: Why Control Is Everything

Managing rolling pressure is a balancing act. Miscalculations can lead to poor quality, material defects, or damage to the rolling mill itself.

Excessive Pressure: The Risk of Defects

If the pressure is too high or distributed improperly, it can cause problems like edge cracking, non-uniform thickness (crown), or poor surface finish. In extreme cases, it can overload the mill bearings and drive motors.

Insufficient Pressure: Failure to Deform

If the pressure is too low, the desired thickness reduction will not be achieved. This means the workpiece will require additional passes, wasting energy, production time, and potentially creating unwanted work-hardening in cold rolling.

The Speed vs. Quality Balance

Increasing rolling speed can boost throughput, but it also alters the friction conditions within the roll bite. This can make it more difficult to maintain a stable process and can negatively impact the final product's dimensional tolerance and surface quality.

Making the Right Choice for Your Goal

Understanding the principles of rolling pressure allows you to manipulate the process to achieve a specific outcome.

- If your primary focus is process efficiency: Concentrate on optimizing the balance between reduction per pass and lubrication to minimize total rolling force and energy consumption.

- If your primary focus is final material properties: Control the process (especially temperature in hot rolling or reduction in cold rolling) to manage work hardening and grain structure.

- If your primary focus is troubleshooting defects: Analyze the shape of the "pressure hill" and the location of the neutral point, as these are often the root cause of issues like cracking or poor surface finish.

Mastering the dynamics of rolling pressure is to master control over the final form and function of the material itself.

Summary Table:

| Factor | Impact on Rolling Pressure |

|---|---|

| Material Yield Strength | Higher strength = Higher pressure required |

| Degree of Reduction | Larger reduction = Exponentially higher pressure |

| Roller Diameter | Smaller diameter = Smaller contact area = Lower total force |

| Friction & Lubrication | More friction = Higher pressure; Lubrication reduces pressure |

| Hot vs. Cold Rolling | Hot rolling requires significantly less pressure than cold rolling |

Achieve precise control over your material processing.

Understanding and managing rolling pressure is critical for achieving the desired material properties, avoiding defects, and optimizing your production efficiency. Whether your goal is process efficiency, superior material properties, or troubleshooting defects, the right equipment is fundamental.

KINTEK specializes in high-quality lab equipment and consumables for material testing and processing. Our solutions help you simulate, analyze, and perfect rolling parameters in a controlled environment.

Contact our experts today to discuss how we can support your laboratory's specific needs in material science and manufacturing research.

Visual Guide

Related Products

- Cylindrical Press Mold with Scale for Lab

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Square Bidirectional Pressure Mold for Lab Use

People Also Ask

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- How do laboratory hydraulic presses and specialized molds influence all-solid-state batteries? Boost Cell Performance

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- How do high-precision molds contribute to Li6PS5Cl electrolyte membrane formation? Achieve Perfect Density and Thickness