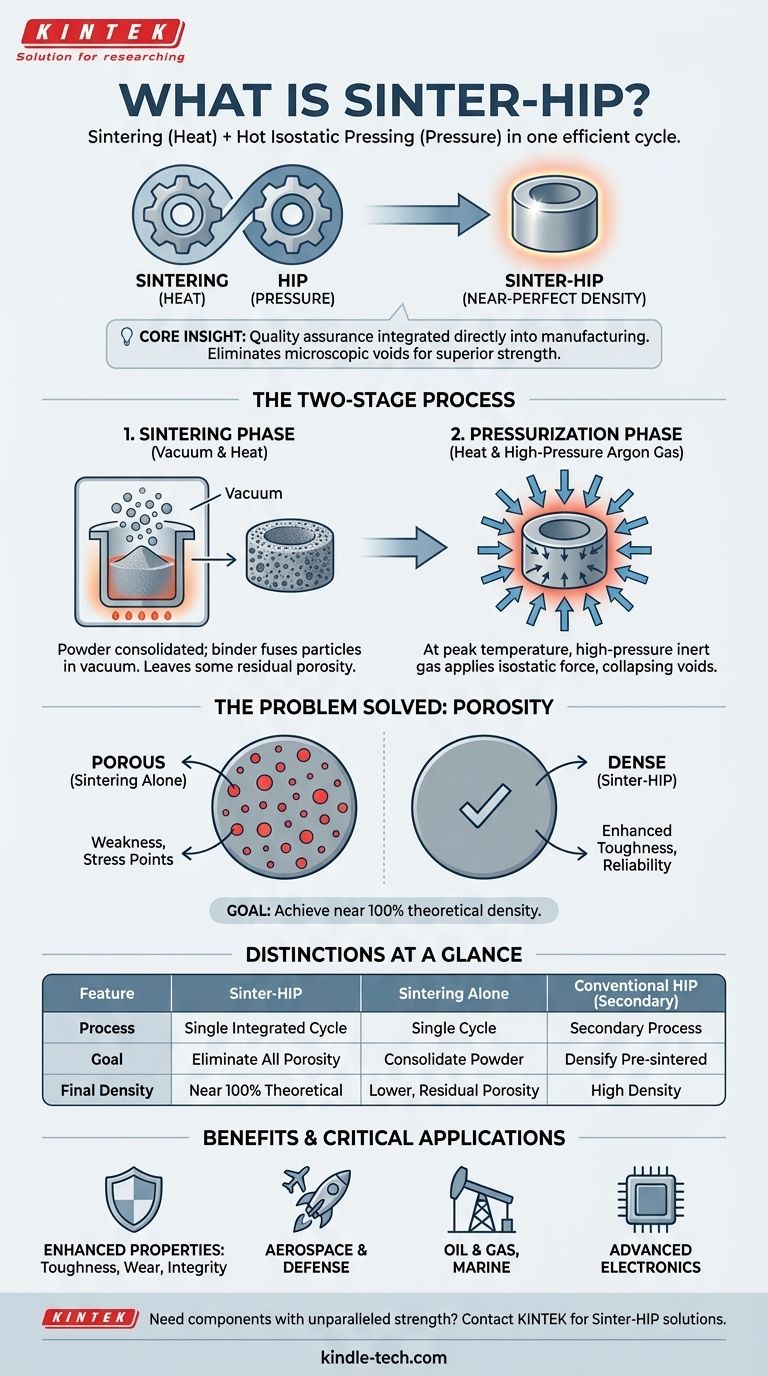

At its core, Sinter-HIP is a high-performance manufacturing process that combines sintering (heat) and hot isostatic pressing (pressure) into a single, efficient cycle. It is designed to consolidate powdered materials, such as cemented carbide or ceramics, into a solid component with virtually zero internal porosity. This results in a final product that is as close to its full theoretical density as possible, dramatically improving its mechanical properties.

The crucial insight is that sinter-HIP is not just a method for forming a part; it is a quality assurance process integrated directly into manufacturing. By applying uniform, high-pressure gas at peak temperature, it actively eliminates the microscopic voids that compromise the strength and reliability of components made by sintering alone.

How Sinter-HIP Achieves Near-Perfect Density

The sinter-HIP process is a carefully orchestrated sequence designed to remove porosity in two stages within a single furnace cycle.

The Sintering Phase

First, the component, formed from a powder material, undergoes vacuum sintering. The part is heated to a high temperature in a vacuum, causing the binder metals within the powder to melt and fuse the primary material particles (like carbide) together.

The Pressurization Phase

At the end of the sintering stage, while the component is still at peak temperature, the process changes. The vacuum is replaced with a high-pressure, inert gas—typically argon.

The Isostatic Advantage

This gas exerts isostatic pressure, meaning it is applied uniformly from all directions. This immense, even pressure effectively squeezes the component, causing the molten binder to fill any remaining microscopic voids and collapsing any internal pores.

The Core Problem Sinter-HIP Solves: Porosity

The primary enemy of high-performance components made from powdered metals is porosity. Sinter-HIP is the definitive solution to this problem.

The Impact of Internal Voids

Porosity refers to the tiny, empty spaces or voids left between particles in a material after it has been compacted and sintered. These voids act as stress concentrators and crack initiation sites.

Even a small amount of residual porosity can severely degrade a component's toughness, strength, and corrosion resistance. For critical applications, such voids are unacceptable points of failure.

The Goal of Full Density

The objective of sinter-HIP is to achieve a component that is as close to 100% of its theoretical density as possible. This means creating a solid, homogenous material with no internal defects, ensuring its properties are predictable and reliable.

Understanding the Trade-offs and Distinctions

Sinter-HIP is a specific technology with clear advantages, but it's important to distinguish it from related processes.

Sinter-HIP vs. Conventional HIP

Conventional Hot Isostatic Pressing (HIP) is often a separate, secondary process performed on an already sintered part in a different machine. Sinter-HIP integrates both steps into one cycle, making it more efficient.

Additionally, sinter-HIP typically operates at lower gas pressures than a standalone HIP cycle, further improving efficiency and environmental impact.

Sinter-HIP vs. Sintering Alone

Standard vacuum sintering can effectively consolidate a part but often leaves behind a small amount of residual porosity. The addition of the isostatic pressure phase in sinter-HIP is what eliminates these final voids, unlocking the material's maximum performance potential.

Key Benefits and Applications

The elimination of porosity directly translates into superior components used in the world's most demanding industries.

Enhanced Material Properties

Components that have been through the sinter-HIP process exhibit significantly improved toughness, wear resistance, and overall structural integrity. This leads to longer service life and greater reliability under extreme conditions.

Critical Industries

Because of its ability to produce highly reliable parts, sinter-HIP is essential in sectors where component failure is not an option. These include aerospace, defense, oil & gas, marine, and advanced electronics.

Making the Right Choice for Your Goal

Selecting the right thermal consolidation process depends entirely on the performance requirements of the final component.

- If your primary focus is maximum performance and reliability: Sinter-HIP is the definitive choice for critical components where internal defects must be eliminated to ensure safety and longevity.

- If your primary focus is cost-efficiency for non-critical parts: Standard vacuum sintering may be sufficient if the application can tolerate a small amount of residual porosity.

- If you are consolidating ceramic parts or repairing casting defects: A standalone, conventional HIP process is often the more appropriate technology for these specific applications.

Ultimately, choosing sinter-HIP is an investment in material integrity, ensuring your components perform predictably and reliably under the most demanding conditions.

Summary Table:

| Feature | Sinter-HIP | Standard Sintering | Conventional HIP |

|---|---|---|---|

| Process | Single, integrated cycle | Single sintering cycle | Secondary, post-sintering process |

| Primary Goal | Eliminate all internal porosity | Consolidate powder into a solid part | Densify pre-sintered parts or castings |

| Final Density | Near 100% theoretical density | Lower, with residual porosity | High density |

| Key Advantage | Maximum performance & reliability | Cost-efficiency for non-critical parts | Effective for specific applications like ceramics |

Need components with unparalleled strength and reliability?

KINTEK specializes in advanced thermal processing solutions. Our expertise in lab equipment and consumables can help you integrate Sinter-HIP technology to produce critical components with near-perfect density for the aerospace, defense, and energy sectors.

Contact our experts today to discuss how Sinter-HIP can enhance your material performance and product longevity.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is vacuum brazed? The Ultimate Guide to High-Purity Metal Joining

- What is an overheated brazed joint indicated by? Signs of a Failed Brazing Process

- What is aluminum vacuum brazing? Achieve Strong, Clean, Flux-Free Aluminum Joining

- What are the technical advantages of using an RMI furnace? Achieve High-Density Ceramics with Precision

- What are the advantages of using a vacuum drying oven for chitosan-zeolite beads? Preserve Pore Structure & Capacity

- How does high-temperature solution treatment optimize 27% Cr super duplex steel? Achieve Peak Microstructural Integrity

- How do high-temperature furnaces facilitate the production of active carbon aerogels? Master Supercapacitor Fabrication

- How does a vacuum oven contribute to solid electrolyte membrane formation? Achieve Dense, Defect-Free Materials