At its core, the pulsed current in Spark Plasma Sintering (SPS) is a specialized form of direct current (DC) that is switched on and off in extremely rapid cycles. This current is passed through a conductive die (typically graphite) and the material being processed, generating intense and rapid heat through electrical resistance (Joule heating). This method allows for the consolidation of powders into a dense solid in a fraction of the time required by conventional furnaces.

The central concept to grasp is that pulsing the current is not just about heating. It allows for momentary peaks of extremely high current density, far exceeding what a continuous current could provide for the same average power. These intense peaks can create additional physical effects that enhance sintering beyond what is possible with simple heat alone.

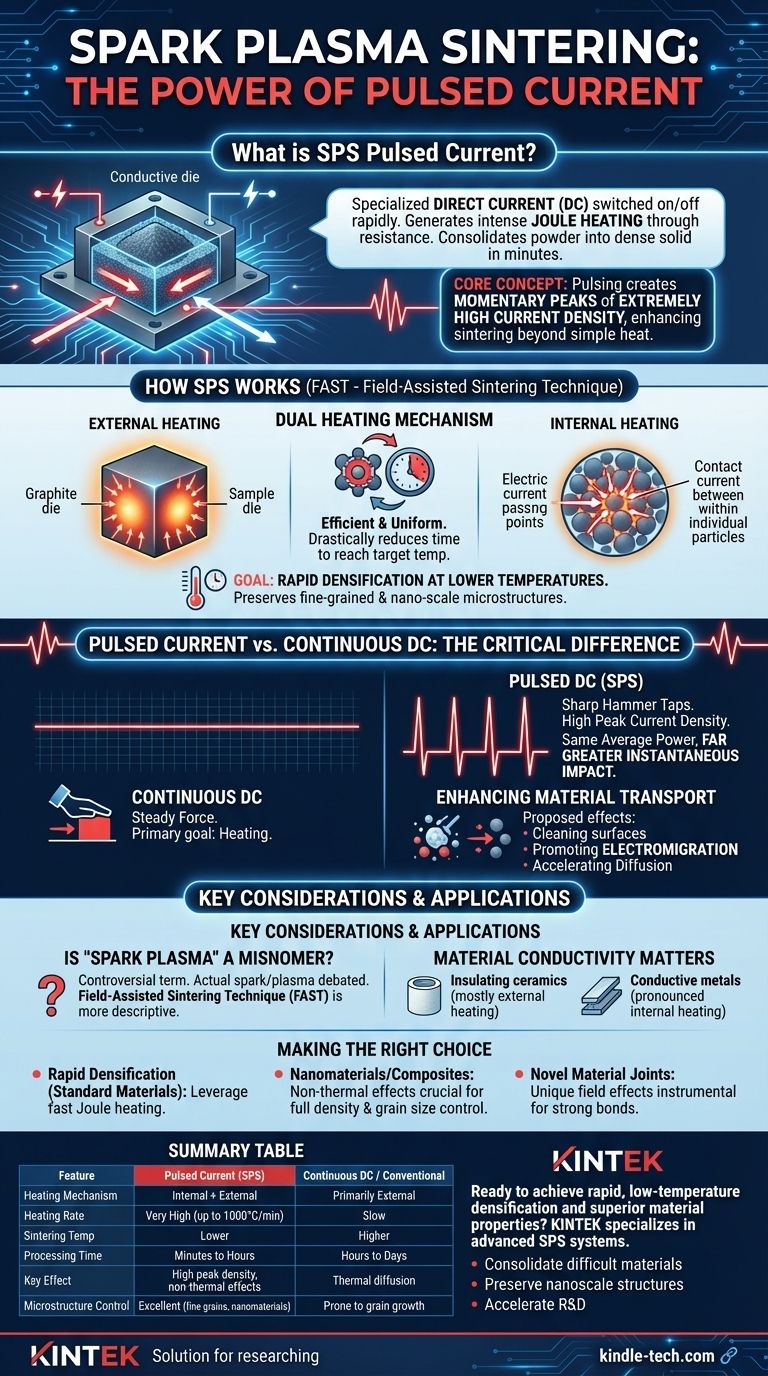

How Spark Plasma Sintering Works

Spark Plasma Sintering, more broadly known as Field-Assisted Sintering Technique (FAST), is a revolutionary powder metallurgy process. It leverages an electric current to achieve densification, departing significantly from traditional furnace-based methods.

The Role of Electric Current

The fundamental principle is Joule heating. An electric current is passed through the entire sintering setup, including the conductive die and, if the sample itself is conductive, the powder particles. The inherent electrical resistance of these components causes them to heat up very rapidly.

The Dual Heating Mechanism

This process creates a unique heating environment. The sample is heated externally by the hot graphite die and internally as the current passes through the contact points between powder particles. This dual-mode heating is incredibly efficient and uniform, drastically reducing the time needed to reach the target sintering temperature.

The Goal: Rapid Densification at Lower Temperatures

The combination of rapid heating rates (up to 1000°C/min), applied pressure, and electrical effects allows materials to become dense at temperatures several hundred degrees lower than in conventional sintering. This helps preserve fine-grained or nano-scale microstructures, leading to materials with superior properties.

Pulsed Current vs. Continuous DC: The Critical Difference

While a continuous DC current can achieve the primary goal of heating, the use of a pulsed DC current introduces another layer of influence on the material.

Defining Pulsed Current

Imagine a light switch being flicked on and off thousands of times per second. A pulsed current operates similarly, with distinct "on" and "off" periods. A common pattern, for example, might be 12 pulses on, followed by 2 pulses off.

The Power of the Peak

This is the most critical concept. To deliver the same total energy as a continuous DC current, a pulsed current must have a significantly higher amplitude during its "on" phase.

Think of it like applying force: a steady push (continuous DC) can be matched in total energy by a series of sharp hammer taps (pulsed DC). While the average force is the same, the instantaneous impact of the hammer is far greater. This high peak current density is believed to be responsible for additional beneficial effects.

Enhancing Material Transport

These momentary, high-density current peaks are thought to enhance the sintering process in ways beyond simple heating. Proposed effects include cleaning contaminants from particle surfaces and promoting electromigration, a phenomenon where atoms are driven to move by the flow of electrons. This can accelerate diffusion and neck formation between particles, leading to faster and more complete densification.

Understanding the Key Considerations

While powerful, the mechanisms of SPS are complex, and it's important to approach the topic with a nuanced understanding.

Is "Spark Plasma" a Misnomer?

The term "Spark Plasma Sintering" is somewhat controversial. The actual generation of a sustained spark or plasma between particles is heavily debated within the scientific community. Many experts prefer the more descriptive term Field-Assisted Sintering Technique (FAST), as it accurately reflects the universally accepted role of the applied electric field and current.

Material Conductivity Matters

The efficiency of internal heating is highly dependent on the electrical conductivity of the powder. For electrically insulating ceramics, heating is almost entirely external, provided by the hot graphite die. For conductive metals and certain ceramics, the internal heating effect is much more pronounced.

A Complex and Active Field of Research

The precise physics behind the enhanced sintering effects of pulsed currents are incredibly complex and remain an active area of research. While the results—faster densification at lower temperatures—are undeniable, the exact contribution of each proposed phenomenon is still being fully mapped.

Making the Right Choice for Your Goal

Understanding the role of the pulsed current helps you leverage the full potential of the SPS/FAST technique for your specific application.

- If your primary focus is rapid densification of standard materials: Recognize that the main advantage of SPS is its fast joule heating, which drastically shortens processing time compared to a conventional furnace.

- If you are working with nanomaterials or difficult-to-sinter composites: The non-thermal effects attributed to high-density pulsed current may be crucial for achieving full density while preventing grain growth.

- If you are developing novel material joints (e.g., ceramic-to-metal): The unique electrical field effects at the interface can be instrumental in forming strong, clean bonds that are difficult to achieve otherwise.

Ultimately, understanding the pulsed current empowers you to treat SPS not just as a faster furnace, but as a sophisticated tool for actively engineering a material's microstructure using an electric field.

Summary Table:

| Feature | Pulsed Current in SPS | Continuous DC / Conventional Sintering |

|---|---|---|

| Heating Mechanism | Internal Joule heating + external die heating | Primarily external radiation/convection |

| Heating Rate | Very high (up to 1000°C/min) | Slow |

| Sintering Temperature | Lower (by hundreds of degrees) | Higher |

| Processing Time | Minutes to hours | Hours to days |

| Key Effect | High peak current density enables non-thermal effects (e.g., electromigration) | Primarily thermal diffusion |

| Microstructure Control | Excellent for preserving fine grains and nanomaterials | Prone to grain growth |

Ready to achieve rapid, low-temperature densification and superior material properties?

KINTEK specializes in advanced lab equipment, including Spark Plasma Sintering (SPS) systems. Our solutions are designed for researchers and engineers working with metals, ceramics, composites, and nanomaterials who need precise control over microstructure.

We help you:

- Consolidate difficult-to-sinter materials with enhanced efficiency.

- Preserve nanoscale grain structures by sintering at lower temperatures.

- Accelerate your R&D with rapid processing times unmatched by conventional furnaces.

Unlock the full potential of Field-Assisted Sintering for your laboratory. Contact KINTEK today to discuss your specific application and how our SPS technology can drive your innovations forward.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- Why must vacuum hot pressing equipment have high-tonnage pressure control for WC/Cu-Zr-Ti amorphous composites?

- Why is a vacuum hot press sintering furnace utilized for nano-AlN? Achieve High Density & Retain Nanostructures

- What are the advantages of pressure in sintering? Achieve Higher Density and Superior Material Properties

- How does a vacuum hot-pressing furnace manufacture high-density NiCrAlY-Mo-Ag? Achieve 100% Densification

- How does a vacuum hot press (VHP) contribute to the densification of Al-Cu-ZrC composite materials? Key VHP Benefits

- How hot isostatic press works? A Guide to Eliminating Porosity and Enhancing Part Performance

- How is heating achieved in an SPS furnace for non-conductive LLZO? Master Indirect Joule Heating Techniques

- What is the core function of a vacuum hot pressing furnace? Achieve 99.5% Density in Al2O3/Cu-Cr Composites