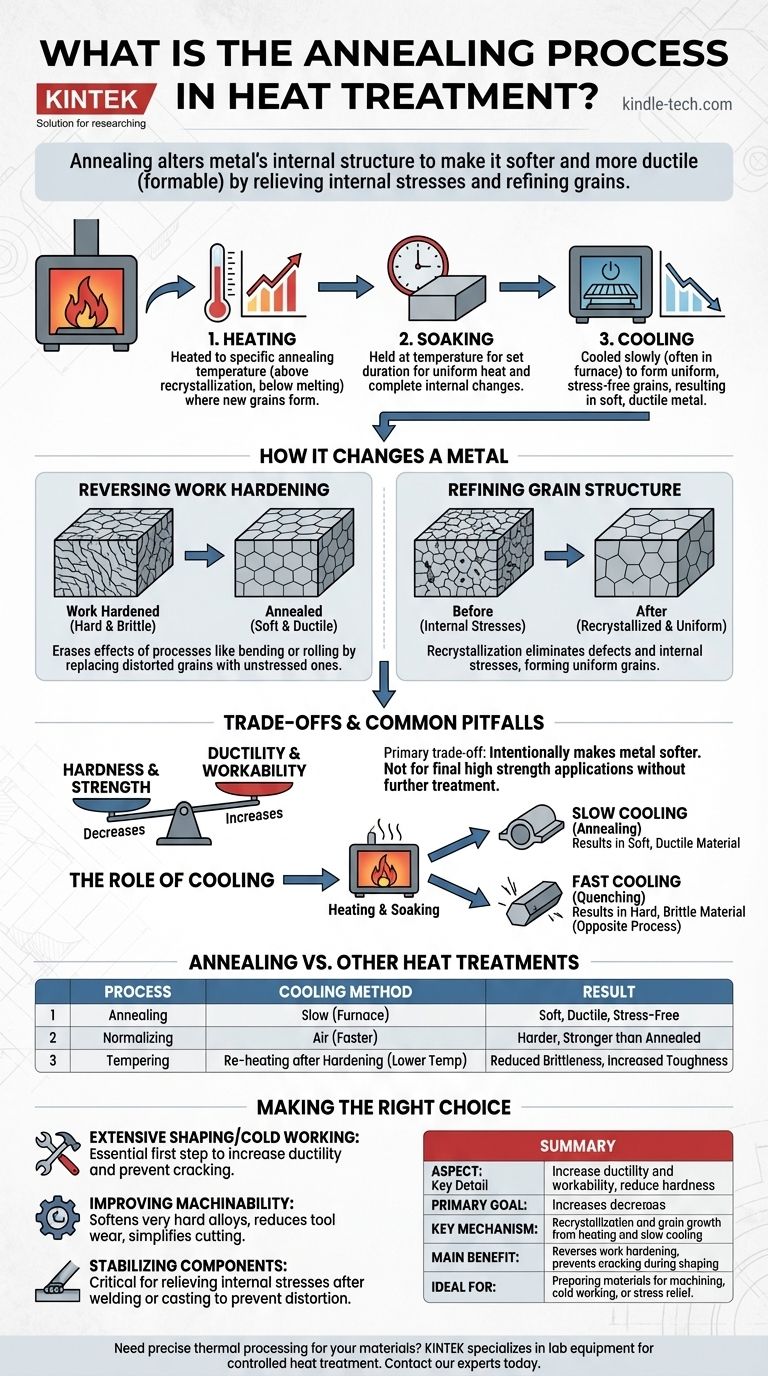

At its core, annealing is a heat treatment process that alters a metal's internal structure to make it softer and more ductile (formable). It involves heating the material to a specific temperature, holding it there, and then cooling it slowly. This procedure relieves internal stresses, refines the grain structure, and reverses the effects of work hardening.

The fundamental purpose of annealing is not to make a metal stronger, but to make it more workable. By carefully resetting the material's microstructure, it trades hardness for ductility, enabling further shaping or machining without the risk of fracture.

How Annealing Fundamentally Changes a Metal

Annealing works by manipulating the crystalline structure, or "grains," within a metal. This controlled process is what gives the material its new, more desirable properties.

The Three Stages of the Process

The annealing cycle consists of three distinct phases.

- Heating: The metal is heated to a specific annealing temperature. This temperature is critical; it must be above the material's recrystallization temperature, where new grains can begin to form, but below its melting point.

- Soaking: The material is held at this temperature for a set duration. This allows the heat to penetrate the entire component uniformly and ensures the internal structural changes are complete.

- Cooling: The material is cooled at a very slow and controlled rate, often by leaving it inside the turned-off furnace. This slow cooling allows new, stress-free grains to form and grow properly, resulting in a soft and ductile final state.

Reversing the Effects of Work Hardening

Processes like bending, rolling, or drawing a metal make it harder and stronger, but also more brittle. This is known as work hardening. Annealing effectively erases this effect by allowing the distorted, stressed grains to be replaced by new, unstressed ones.

Refining the Grain Structure

The heat applied during annealing gives the atoms within the metal enough energy to move and rearrange themselves. This process, called recrystallization, eliminates the defects and internal stresses built up from previous processing. The slow cooling that follows ensures the new grains are uniform and coarse, which is characteristic of a soft, ductile material.

Understanding the Trade-offs and Common Pitfalls

While highly effective, annealing is a specific tool for a specific job. Understanding its trade-offs is crucial for correct application.

The Primary Trade-off: Hardness for Ductility

The main consequence of annealing is a significant reduction in hardness and tensile strength. You are intentionally making the metal softer. If the final application requires high strength or wear resistance, the material will almost certainly need another form of heat treatment (like hardening and tempering) after the shaping and machining processes are complete.

The Critical Role of Slow Cooling

The cooling rate is arguably the most important variable. If the metal is cooled too quickly (a process known as quenching), it will harden instead of soften. This is the basis for a different heat treatment—hardening—which is the functional opposite of annealing.

Annealing vs. Other Heat Treatments

It is easy to confuse annealing with similar processes.

- Normalizing: This also involves heating, but the cooling is done in open air. This faster cooling rate results in a material that is harder and stronger than an annealed one.

- Tempering: This is a process performed after a metal has been hardened. It involves heating to a much lower temperature to reduce some of the extreme brittleness that comes with hardening, thereby increasing toughness.

Making the Right Choice for Your Goal

Selecting the correct heat treatment depends entirely on what you need to achieve with the material.

- If your primary focus is preparing a material for extensive shaping or cold working: Annealing is the essential first step to increase ductility and prevent cracking during forming.

- If your primary focus is improving the machinability of a very hard alloy: Use annealing to soften the metal, which reduces tool wear and simplifies the cutting process.

- If your primary focus is stabilizing a component after welding or casting: Annealing is critical for relieving internal stresses that could otherwise lead to distortion or failure over time.

Ultimately, annealing empowers you to control a material's properties, transforming a brittle component into a stable and workable foundation for your project.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Goal | Increase ductility and workability, reduce hardness. |

| Key Mechanism | Recrystallization and grain growth from heating and slow cooling. |

| Main Benefit | Reverses work hardening, prevents cracking during shaping. |

| Ideal For | Preparing materials for machining, cold working, or stress relief. |

Need precise thermal processing for your materials?

KINTEK specializes in the lab equipment and consumables essential for controlled heat treatment processes like annealing. Whether you are developing new alloys or preparing samples for testing, our reliable furnaces and temperature control systems ensure you achieve the exact material properties you need.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and ensure your heat treatment success.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control