The primary ASTM standard for sieving is not a single document, but rather a pair of standards that work together. The most critical standard for the physical sieve is ASTM E11, which specifies the manufacturing and calibration of the sieve itself, while ASTM C136 is the most common standard test method for conducting a sieve analysis on aggregates.

To achieve accurate and repeatable results, you must understand that standardization applies to both the tool and the technique. Using a certified sieve (ASTM E11) is pointless without a consistent, documented procedure (like ASTM C136), and vice versa.

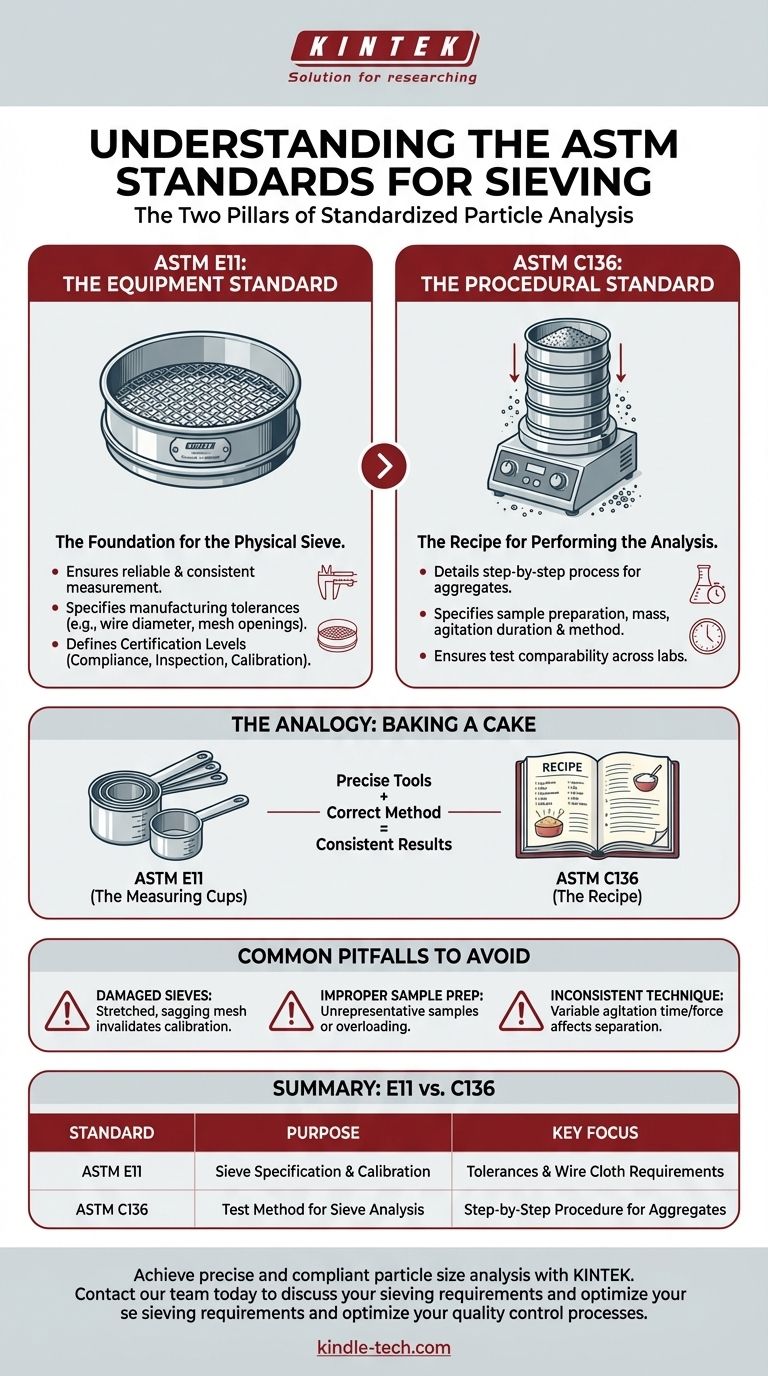

The Two Pillars of Standardized Sieving

A common point of confusion is believing there is one single "sieving standard." In reality, achieving a valid result relies on two independent but codependent standards: one governing the equipment and one governing the process.

ASTM E11: The Standard for the Sieve Itself

ASTM E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves," is the foundational standard for the physical equipment. It does not tell you how to perform a test.

Instead, ASTM E11 ensures that a sieve from any manufacturer is a reliable and consistent measuring device. It specifies critical parameters like the permissible variations in wire diameter and the average opening size of the mesh.

The standard defines different levels of certification. Compliance Sieves are manufactured to meet the specification, while higher-grade Inspection Sieves and Calibration Sieves have been measured and verified to have tighter tolerances.

ASTM C136: The Standard for the Test Method

ASTM C136 / C136M, "Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates," provides the recipe for performing the analysis. This is the procedural standard.

This document details the step-by-step process, including how to prepare the material sample, the proper mass to use based on particle size, and the required duration and method of agitation.

It also outlines the necessary calculations for determining the particle size distribution and fineness modulus. Following C136 ensures that a test performed in one lab is directly comparable to a test performed in another.

Why This Distinction is Critical

Think of it like baking a cake. ASTM E11 is the standard that ensures your measuring cups are accurate. ASTM C136 is the recipe that tells you how to use them.

If your measuring cups are inaccurate (non-compliant sieves), you can follow the recipe perfectly and still get the wrong result.

Conversely, if you have perfect measuring cups (E11-certified sieves) but don't follow the recipe (deviate from the C136 method), your results will be inconsistent and unreliable.

Common Pitfalls in Sieve Analysis

Even with the correct standards, errors can invalidate your results. Adherence to the process is paramount.

Using Non-Compliant or Damaged Sieves

The integrity of the sieve is non-negotiable. A sieve with stretched, sagging, or torn mesh, or one with a distorted frame, is no longer a calibrated instrument.

Regular visual inspection for damage, cleanliness, and tautness of the mesh is a critical first step before any analysis.

Improper Sample Preparation

The sample being tested must be a true representation of the entire batch of material. Using proper sampling techniques, like quartering or using a sample splitter, is essential.

Furthermore, C136 specifies the appropriate sample size. A sample that is too large will overload the sieves, preventing particles from having a chance to pass through the openings, a phenomenon known as "blinding."

Inconsistent Sieving Technique

The standard specifies how long and how aggressively the sample must be agitated. Insufficient sieving time will result in a sample that is not fully separated.

Whether using a mechanical shaker or agitating by hand, the technique must be consistent for results to be comparable over time. This is a primary reason mechanical shakers are preferred for quality control environments.

Making the Right Choice for Your Goal

To ensure your results are defensible and accurate, you must consider both the equipment and the procedure.

- If your primary focus is equipment purchasing and calibration: Source sieves that are certified as compliant with ASTM E11 and implement a regular inspection and verification schedule.

- If your primary focus is performing daily tests: Adhere strictly to the methodology in ASTM C136, paying special attention to sample size, sieving time, and preventing sieve overloading.

- If your primary focus is quality assurance and compliance: Require both E11-compliant sieves and the C136 test procedure in your quality management system and internal training documents.

By understanding and applying both the equipment and procedural standards, you ensure your particle size analysis is not just a measurement, but a verifiable fact.

Summary Table:

| Standard | Purpose | Key Focus |

|---|---|---|

| ASTM E11 | Sieve Specification & Calibration | Defines manufacturing tolerances and wire cloth requirements for the sieve itself. |

| ASTM C136 | Test Method for Sieve Analysis | Provides the step-by-step procedure for conducting the analysis on aggregates. |

Achieve precise and compliant particle size analysis with KINTEK.

Understanding the nuances of ASTM standards is just the first step. Consistent, reliable results depend on using high-quality, certified sieves and following rigorous procedures.

KINTEK specializes in supplying a full range of ASTM E11-compliant test sieves and reliable lab equipment to meet your specific needs. Our experts can help you select the right tools and establish best practices based on standards like ASTM C136.

Ensure your lab's data is accurate and defensible. Contact our team today to discuss your sieving requirements and optimize your quality control processes.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What range of particle size does the sieve analysis apply? Master the 25 Micron to 1 mm Standard

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- What are the standard test sieves for ASTM? Ensure Accuracy with ASTM E11 Compliant Sieves

- Which equipment is operated for sieves when perform sieving tests? Achieve Accurate Particle Size Analysis

- What are advantages and disadvantages of sieving method? A Guide to Reliable & Cost-Effective Particle Sizing