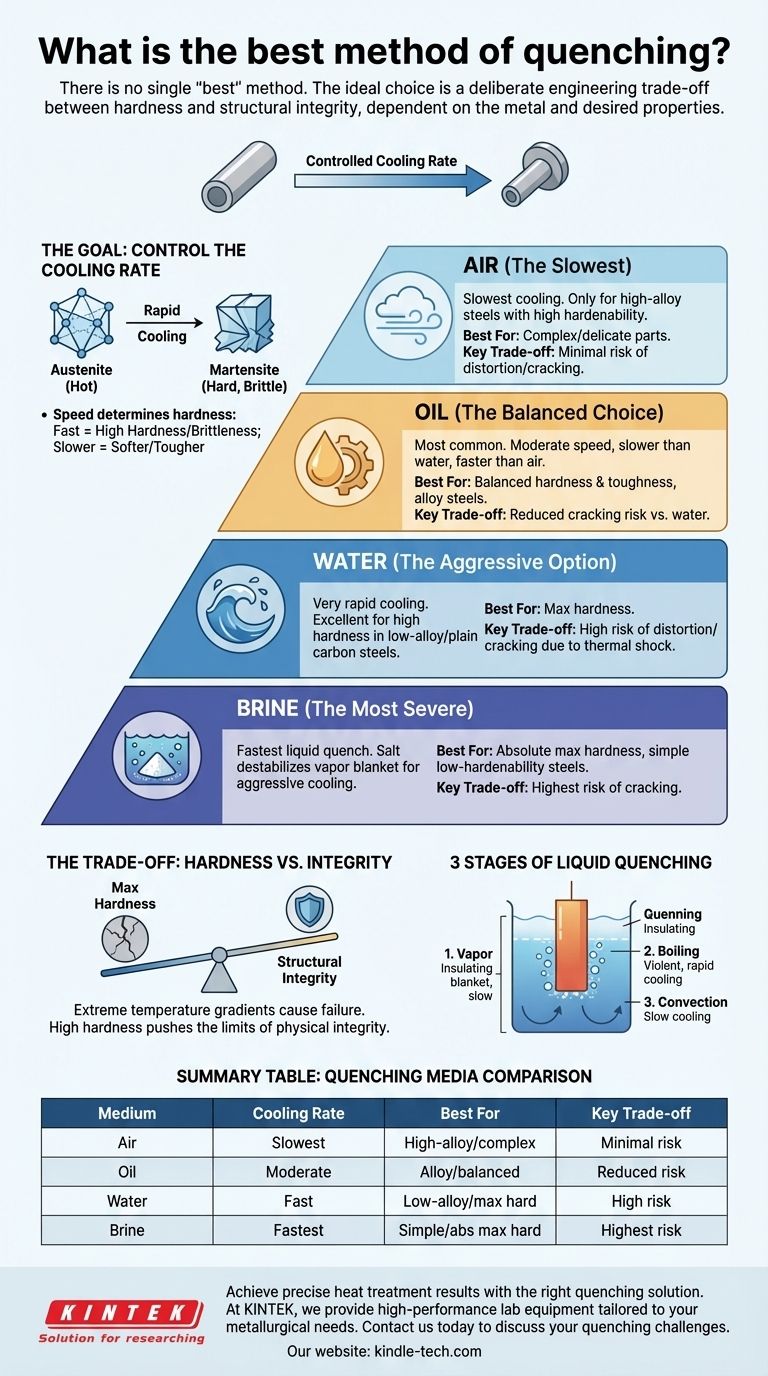

There is no single "best" method of quenching. The ideal method is entirely dependent on the type of metal being treated and the specific properties you need to achieve, such as maximum hardness or dimensional stability. The most common quenchants are air, oil, water, and brine, each offering a different cooling rate and associated trade-offs.

The "best" quenching method is the one that cools a specific metal just fast enough to achieve the desired metallurgical transformation, without cooling so fast that it causes the part to crack, warp, or develop internal stresses. The choice is a deliberate engineering trade-off between hardness and structural integrity.

The Goal of Quenching: Controlling the Cooling Rate

Quenching is not simply about making hot metal cold. It is a precise thermal process designed to lock a specific crystalline structure into place.

The Race to Hardness

For steels, heating the metal transforms its internal structure into a state called austenite. The goal of quenching is to cool the steel so rapidly that the austenite does not have time to change back into its softer forms.

Instead, this rapid cooling traps the structure in a hard, brittle state known as martensite. The speed of this cooling process is the single most important factor determining the final hardness of the part.

Why Cooling Speed is Everything

The cooling rate directly dictates the final properties. A very fast quench produces a high percentage of martensite, resulting in extreme hardness but also significant brittleness.

A slower quench may not form as much martensite, leading to a softer but more ductile and tougher final part. The key is to match the cooling rate to the material's requirements.

A Breakdown of Common Quenching Media

Each quenching medium removes heat at a different speed. Understanding this hierarchy is fundamental to selecting the right process.

Air (The Slowest)

Air quenching, or "normalizing," provides the slowest cooling rate. It is suitable only for certain high-alloy steels that have very high hardenability—the innate ability to form martensite even with slow cooling.

The primary benefit of air quenching is the minimal risk of distortion or cracking, making it ideal for complex or delicate parts made from appropriate materials.

Oil (The Balanced Choice)

Oil is the most widely used quenchant because it offers a balanced cooling rate—slower and less severe than water, but much faster than air.

This moderate speed provides a good combination of hardness and toughness while significantly reducing the risk of cracking compared to more aggressive methods.

Water (The Aggressive Option)

Water removes heat very rapidly, making it excellent for achieving high hardness in low-alloy or plain carbon steels that require a fast quench.

However, its speed is also its biggest liability. The intense thermal shock creates massive internal stresses, carrying a high risk of distortion and quench cracking, especially in complex shapes.

Brine (The Most Severe)

A solution of salt and water (brine) provides the fastest possible liquid quench. The salt destabilizes the vapor jacket that forms around the hot part, allowing for more consistent and aggressive heat transfer.

Brine is used when absolute maximum hardness is required for simple, low-hardenability steels. The risk of cracking is even higher than with plain water.

Understanding the Trade-offs: Hardness vs. Integrity

Choosing a quenching method is a balancing act. Pushing for maximum hardness often compromises the physical integrity of the component.

The Three Stages of Liquid Quenching

When a hot part enters a liquid like oil or water, the cooling process occurs in three distinct phases.

- The Vapor Stage: An insulating blanket of vapor immediately surrounds the part. Cooling is relatively slow and uneven in this stage.

- The Boiling Stage: The vapor blanket collapses, and violent boiling begins at the part's surface. This is where heat transfer is most rapid and the majority of hardening occurs.

- The Convection Stage: The surface temperature drops below the liquid's boiling point. Cooling slows dramatically, now driven by simple convection.

The Risk of Cracking and Distortion

The extreme temperature gradients caused by a fast quench are the primary cause of failure. As the surface of the part cools and contracts rapidly, the still-hot interior resists this change, creating immense internal stress that can warp the part or cause it to crack.

Material Hardenability Matters

Different steel alloys are designed with different levels of hardenability. A high-carbon steel like W1 needs a very fast quench (water/brine) to get hard. In contrast, an air-hardening tool steel like A2 is rich in alloys that allow it to form martensite even when cooled slowly in air. Using water on A2 would almost certainly cause it to shatter.

Selecting the Right Quenchant for Your Goal

Base your decision on the material you are using and the properties you need to prioritize.

- If your primary focus is maximum hardness on a simple carbon steel part: Use brine or water, but be fully aware of the high risk of cracking and plan for it.

- If your primary focus is a good balance of hardness and toughness in an alloy steel: Oil is the most reliable and common choice, offering excellent results with a manageable risk of distortion.

- If your primary focus is minimizing distortion on a sensitive part made from a high-alloy steel: Air or a specialized slow-speed quenching oil is the correct path, provided the steel has sufficient hardenability.

Ultimately, a successful quench is the result of a deliberate choice, not a search for a single "best" solution.

Summary Table:

| Quenching Medium | Cooling Rate | Best For | Key Trade-off |

|---|---|---|---|

| Air | Slowest | High-alloy steels, complex parts | Minimal risk of cracking/distortion |

| Oil | Moderate (Balanced) | Alloy steels, balanced hardness & toughness | Reduced cracking risk vs. water |

| Water | Fast | Low-alloy/carbon steels, max hardness | High risk of cracking and distortion |

| Brine | Fastest | Simple carbon steels, absolute max hardness | Highest risk of cracking |

Achieve precise heat treatment results with the right quenching solution.

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to your laboratory's specific metallurgical needs. Whether you're working with air-hardening steels or require aggressive brine quenching, our expertise ensures you achieve the perfect balance of hardness and structural integrity.

Contact us today to discuss your quenching challenges and discover how KINTEK's solutions can enhance your process efficiency and product quality.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the disadvantages of liquid phase sintering? Key Risks and Trade-offs Explained

- What are the advantages of SPS furnaces for UHTCMCs? Achieve Superior Density and Microstructure

- What is the difference between batch type and continuous type furnace? Choose the Right Heat Treatment Process

- Does sintering increase density? Master the Thermal Process for Superior Material Performance

- How is heat transfer in liquids different from that in a vacuum? Mastering Thermal Management for Your Lab

- What is the critical role of a vacuum furnace in the calcination of TiO2? Optimize Your Powder Microstructure

- What is plasma nitriding? Achieve Superior Wear Resistance and Component Durability

- Can a furnace pressure switch cause short cycling? Diagnose the Real Cause of Intermittent Shutdowns