To correctly install electrodes, you must first insert them into the electrolytic cell, then carefully adjust their position to be centered, ensuring they do not touch the cell walls or bottom. After achieving the proper alignment and depth required for your experiment, securely tighten the support clamps and double-check the final positioning.

The physical installation of electrodes is just one step in a larger process. To ensure accurate results and protect your equipment, you must adopt a full lifecycle approach that includes pre-installation inspection, precise positioning, correct electrical connection, and proper post-experiment maintenance.

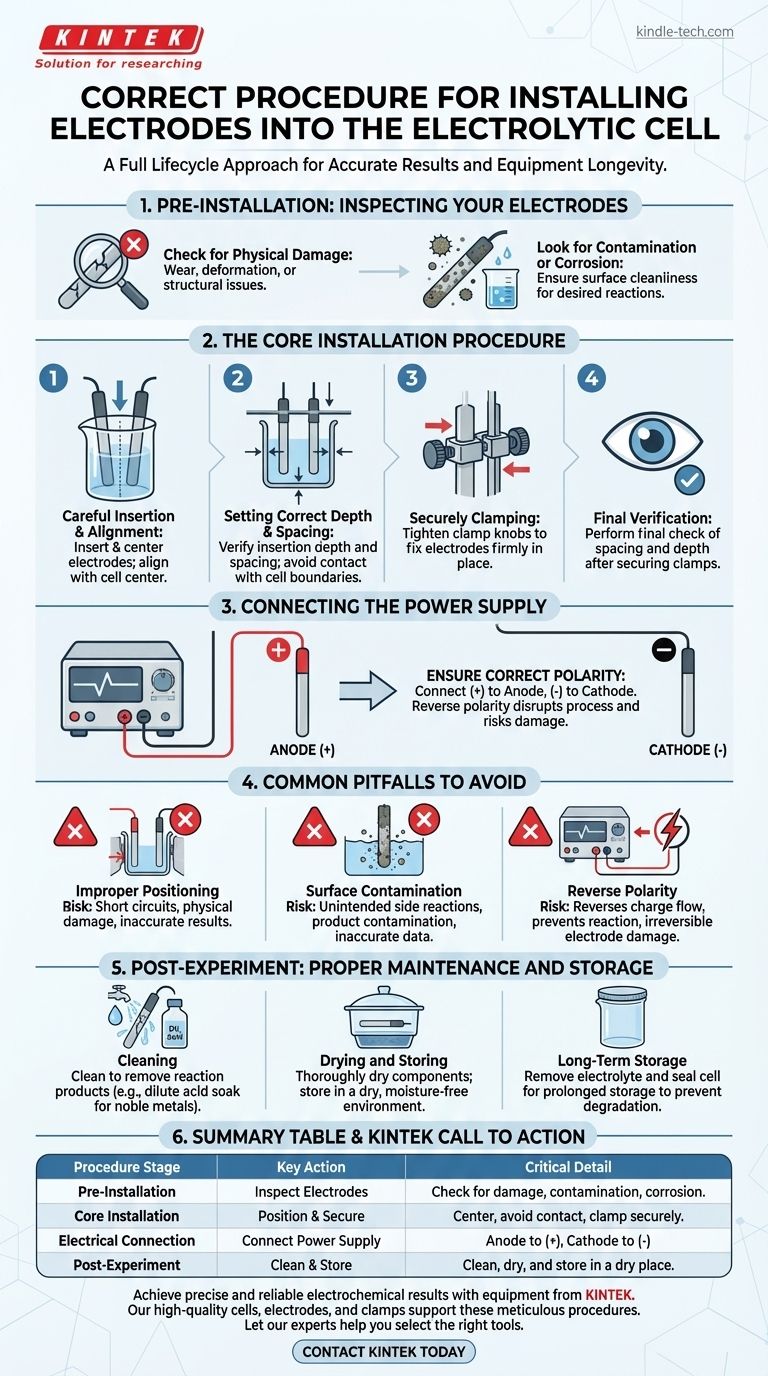

Pre-Installation: Inspecting Your Electrodes

Before introducing electrodes into the cell, a thorough inspection is critical. This preventative step ensures the integrity of your experiment from the start.

Check for Physical Damage

Examine the electrode surfaces for any signs of wear, deformation, or physical damage. A compromised electrode structure can lead to inconsistent results.

Look for Contamination or Corrosion

Inspect the electrodes for any surface dirt, residue from previous reactions, or signs of corrosion. Clean surfaces are essential for the desired chemical reactions to occur without interference.

The Core Installation Procedure

Proper positioning is paramount for the correct function of an electrolytic cell. Follow these steps methodically.

Careful Insertion and Alignment

Gently insert the electrodes into the electrolytic cell. Slowly adjust the support mechanism to align the electrodes with the center of the cell.

Setting the Correct Depth and Spacing

Position the electrodes so they do not make contact with the cell's bottom or side walls, which could cause a short circuit or damage the cell. Verify that the insertion depth and the spacing between the electrodes meet the specific parameters of your experiment.

Securely Clamping the Electrodes

Once the electrodes are in their final position, tighten the clamp knobs on the support structure. This ensures they remain fixed and do not move during the experiment.

Final Verification

After securing the clamps, perform a final check to confirm that the spacing and depth have not shifted. This final verification is crucial for experimental reproducibility.

Connecting the Power Supply

A correct electrical connection is as important as the physical installation.

Identify the Anode and Cathode

The positive terminal of your power supply connects to the anode, and the negative terminal connects to the cathode. These electrodes are typically made of inert materials like graphite or platinum.

Ensure Correct Polarity

Pay close attention to the positive (+) and negative (-) terminals. Connecting the electrodes with reverse polarity will disrupt the intended electrochemical process and can damage your equipment.

Common Pitfalls to Avoid

Mistakes during setup can invalidate your results and risk damage to the cell or electrodes.

The Risk of Improper Positioning

If an electrode touches the cell wall or bottom, it can create a short circuit or physically damage the apparatus. Imprecise spacing will alter the electrical field and affect reaction rates.

The Impact of Surface Contamination

Dirty or corroded electrodes introduce impurities into the system. This can lead to unintended side reactions, contaminate your product, and produce inaccurate data.

The Danger of Reverse Polarity

Incorrectly connecting the anode and cathode reverses the flow of charge and the location of oxidation and reduction. This will prevent the desired reaction from occurring and may cause irreversible damage to the electrodes.

Post-Experiment: Proper Maintenance and Storage

Extending the life of your equipment requires disciplined post-use care.

Cleaning the Electrodes

After use, clean the electrodes to remove any reaction products. For noble metals like platinum, this may involve soaking them in a dilute acid (e.g., 1M nitric acid) followed by a thorough rinse with deionized water.

Drying and Storing Components

Thoroughly dry the electrodes and the reaction vessel before storage. Store them in a dry, moisture-free environment to prevent corrosion or deterioration.

Long-Term Storage Protocol

If the cell will not be used for a long time, the electrolyte should be removed and the cell sealed for storage. This prevents slow degradation from prolonged exposure.

Applying This to Your Work

Following a rigorous procedure is not about ceremony; it is about guaranteeing the quality of your results.

- If your primary focus is experimental accuracy: Pre-inspection for contamination and precise, verified positioning are the most critical steps for you.

- If your primary focus is equipment longevity: Diligent post-use cleaning, drying, and proper storage will have the greatest impact on extending the life of your electrodes and cell.

- If your primary focus is safety and reliability: Always double-check polarity before turning on the power and ensure electrodes are securely clamped to prevent movement or short circuits.

By treating electrode installation as a complete, multi-stage process, you ensure the integrity of your experiment and the reliability of your results.

Summary Table:

| Procedure Stage | Key Action | Critical Detail |

|---|---|---|

| Pre-Installation | Inspect Electrodes | Check for physical damage, contamination, or corrosion. |

| Core Installation | Position & Secure | Center electrodes, avoid contact with cell walls, and securely clamp. |

| Electrical Connection | Connect Power Supply | Anode to positive (+), cathode to negative (-) terminal. |

| Post-Experiment | Clean & Store | Clean with appropriate solvents, dry thoroughly, and store in a dry place. |

Achieve precise and reliable electrochemical results with equipment from KINTEK.

Our high-quality electrolytic cells, electrodes (including graphite and platinum), and support clamps are designed for durability and performance, directly supporting the meticulous procedures outlined above. Proper equipment is fundamental to experimental success.

Let our experts help you select the right tools for your specific laboratory needs.

Contact KINTEK today to discuss your application and ensure the integrity of your experiments.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte