The fundamental difference between hot type and cold type is the medium used to create the characters for printing. Hot type uses molten metal to cast physical letters, while cold type uses photographic or digital methods that do not involve heat.

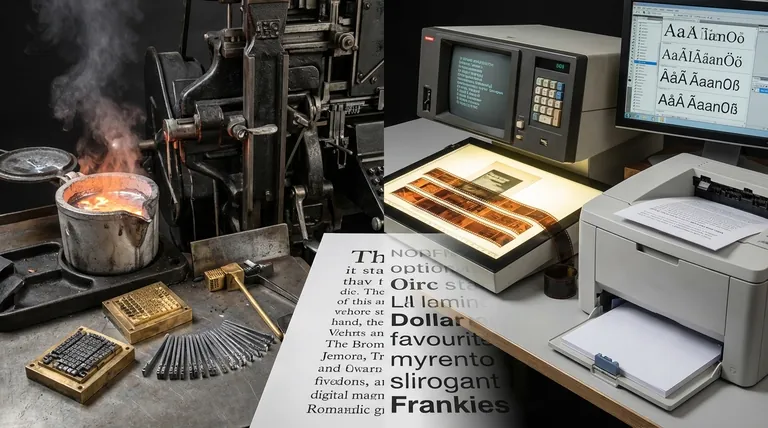

The transition from hot metal typesetting to cold type represents one of the most significant technological shifts in the history of publishing. It marked the move from a heavy, mechanical, and industrial process to a lighter, faster, and more flexible photographic and digital workflow.

What is Hot Type? The Age of Molten Metal

Hot type, or hot metal typesetting, dominated the printing industry from the late 19th century until the mid-20th century. The name comes from the core of its process: casting type from a molten alloy of lead, tin, and antimony.

The Core Principle: Casting with Lead

At its heart, hot type is a mechanical process. An operator uses a machine to assemble molds (called matrices) for characters, which are then filled with molten metal to create either a single line of text or individual letters.

The Linotype Machine

The Linotype machine, invented in 1886, was a revolutionary device. An operator would type on a keyboard, and the machine would assemble a line of brass letter molds, cast it as a single metal slug (a "line-o'-type"), and then distribute the molds back to be used again. This was incredibly fast and efficient for newspapers and magazines.

The Monotype System

The Monotype system was a two-part process that offered higher quality and more flexibility. A keyboard machine punched a paper tape, which was then fed into a separate casting machine that produced individual metal letters. This made correcting a single typo much easier, as you only had to replace one character instead of recasting an entire line.

The Physical Reality

The output of any hot type process was a tangible, heavy block of metal type. These slugs and letters had to be physically arranged by hand into a frame (a chase) to form a page, which was then used in a printing press. The environment was loud, hot, and required highly skilled mechanical operators.

What is Cold Type? The Photographic Revolution

Cold type refers to any typesetting technology that does not involve molten metal. Its emergence in the 1950s and 60s signaled the end of the hot metal era, bringing with it a new level of design freedom and accessibility.

The Core Principle: Type on Film

The first wave of cold type was phototypesetting. Instead of casting metal, these machines projected light through a film negative of a character, through a lens, and onto photosensitive paper or film.

The Phototypesetting Process

An operator would type the text, and the phototypesetter would mechanically select the correct character negative and expose it to the photographic paper. The result was a crisp, high-resolution column of text—a galley proof—ready to be physically cut and pasted onto a layout board.

The Rise of Digital Typesetting

Phototypesetting paved the way for fully digital type. In this modern process, fonts exist as data (vector or bitmap outlines). Computers and software like Adobe InDesign are used to arrange this digital type on a screen, and the final output is sent directly to a printer or an imagesetter that creates a printing plate.

The Key Advantages

The move to cold type was revolutionary. The process was silent, safe, and did not require a foundry. It gave designers unprecedented control over sizing, spacing (kerning), and layout, as type could be scaled, slanted, and overlapped with ease.

Understanding the Key Differences

The shift from hot to cold type was not just an upgrade; it fundamentally changed the craft of publishing.

The Medium

This is the most critical distinction. Hot type creates a three-dimensional metal object. Cold type creates a two-dimensional image on film or, ultimately, as digital data on a screen.

The Process

Hot type is a mechanical, industrial process. It involves foundries, heavy machinery, and physical assembly. Cold type is a photographic and electronic process, involving light, lenses, and eventually, just pixels and code.

Flexibility and Design

Hot type was rigid. To change a font's size, you had to switch to a different set of physical molds. Cold type offered immense flexibility, allowing type to be scaled, stretched, and manipulated in ways that were impossible with metal.

Skill and Labor

Operating a Linotype machine required a highly trained and often unionized tradesperson. The rise of cold type, especially desktop publishing, democratized the process, shifting the required skills from mechanical operation to graphic design and digital layout.

Why This Distinction Matters Today

Understanding this evolution from hot to cold provides crucial context for anyone involved with the printed word.

- If your primary focus is design history: This technological shift explains the explosion in typographic creativity in the late 20th century and is the direct ancestor of the digital tools we use today.

- If your primary focus is graphic design: Recognizing the physical limitations of hot metal gives you a deeper appreciation for the boundless freedom that digital type provides.

- If your primary focus is traditional letterpress: The distinction is fundamental, as you may work with original hot metal slugs or with modern polymer plates created using cold type (digital) methods to mimic the classic effect.

Ultimately, the journey from hot metal to digital data is the story of how typography was untethered from its physical, mechanical constraints and transformed into a fluid, expressive element of modern design.

Summary Table:

| Feature | Hot Type | Cold Type |

|---|---|---|

| Medium | Molten metal (lead, tin, antimony) | Photographic film or digital data |

| Process | Mechanical casting (Linotype/Monotype) | Photographic or digital typesetting |

| Output | 3D metal slugs or individual letters | 2D images on film or digital files |

| Flexibility | Rigid; size changes require new molds | Highly flexible; scalable and editable |

| Skill Set | Mechanical operation and foundry work | Graphic design and digital layout |

Need precision equipment for your lab's printing or material testing workflows? KINTEK specializes in high-quality lab equipment and consumables, serving diverse laboratory needs. Whether you're exploring traditional techniques or modern digital processes, our solutions ensure accuracy and efficiency. Contact us today to discover how we can support your projects with reliable, cutting-edge tools!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is the control of moisture evaporation critical in the Cu-Cl cycle? Optimize Particle Quality & Reactivity

- What affects the conductivity of materials? Unlock the Science Behind Electrical Performance

- What are the hazards in heat treatment operation? Mitigate Thermal, Chemical, and Mechanical Risks

- Is deposition physical or chemical? Unraveling the Science of Phase Transitions

- Does temperature affect compression? Understanding the Critical Role of Heat in Material Behavior

- How does the stirring speed affect silver nanowires morphology? Master Agitation for High-Purity Synthesis

- What are the different types of biomass reactors? Choosing the Right Design for Your Conversion Process

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration