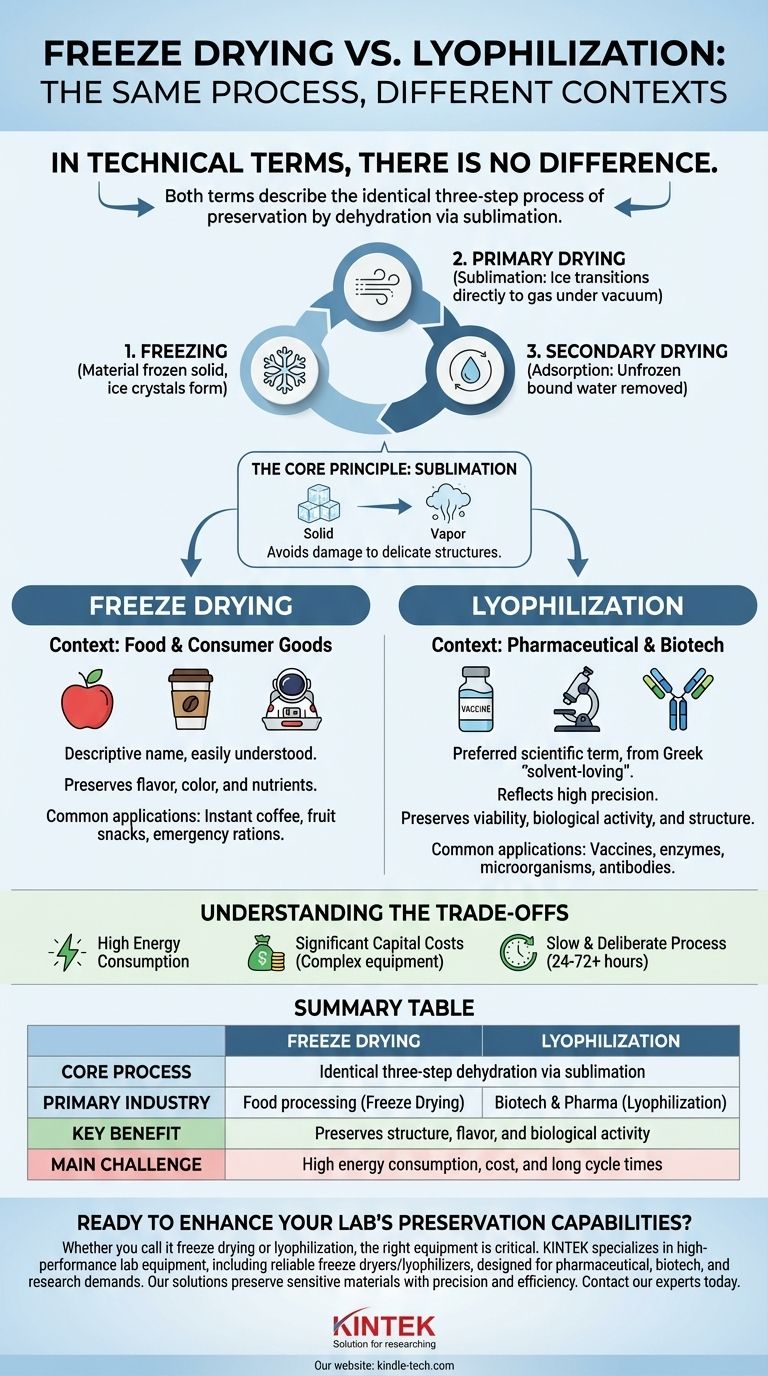

In technical terms, there is no difference. Freeze drying and lyophilization are two names for the exact same process of dehydration. The core distinction lies not in the science but in the industry context where the term is used, with "freeze drying" common in food processing and "lyophilization" preferred in pharmaceutical and biological fields.

The essential takeaway is that "freeze drying" and "lyophilization" describe the identical three-step process of preservation by dehydration. The term you encounter simply reveals the application: preserving the flavor of coffee versus preserving the viability of a vaccine.

The Underlying Science: How It Actually Works

To understand why this process is so valuable, you need to look past the name and focus on the method itself. It is a sophisticated dehydration technique designed to remove water while causing minimal damage to a product's physical structure.

The Core Principle: Sublimation

The entire process hinges on a physical phenomenon called sublimation. This is where a substance, in this case, ice, transitions directly from a solid state to a gas state without ever becoming a liquid.

By skipping the liquid water phase, the process avoids the significant structural damage—like shrinking and toughening—that conventional heat-based dehydration causes to delicate cellular structures.

The Three Key Stages

The process is meticulously controlled and occurs in three distinct phases:

- Freezing: The material is frozen solid. The way it is frozen (e.g., the cooling rate) is critical as it determines the size of the ice crystals, which affects the final product's quality.

- Primary Drying (Sublimation): The pressure is lowered significantly, creating a vacuum. A small amount of heat is then added, providing the energy for the frozen water to sublimate directly into water vapor. This phase removes about 95% of the water.

- Secondary Drying (Adsorption): The temperature is raised slightly to remove any remaining, unfrozen water molecules that are bound to the material.

The End Result: A Preserved Structure

The final product is a highly porous, structurally intact, and extremely lightweight version of the original. Because the underlying scaffold is preserved, it can be rehydrated almost instantly while retaining much of its original shape, flavor, and biological activity.

Why Do Two Names Exist for the Same Thing?

The dual terminology is a simple matter of professional convention and etymology. Each term evolved to serve the needs and culture of a specific industry.

"Freeze Drying": The Food Industry Standard

In the context of food and consumer goods—from instant coffee to astronaut meals to fruit snacks—the term freeze drying is used. It is a straightforward, descriptive name that is easily understood by a broad audience. It clearly communicates the core actions: freezing, then drying.

"Lyophilization": The Scientific & Pharmaceutical Term

In pharmaceutical, biotech, and academic research settings, lyophilization is the preferred term. It is used when preserving sensitive materials like vaccines, antibodies, enzymes, and microorganisms.

The name comes from Greek roots meaning "solvent-loving," which refers to the ease with which the final product can be rehydrated. This scientific-sounding term reflects the high degree of precision and validation required in these critical applications.

Understanding the Trade-offs

While incredibly effective, this method is not without its significant challenges and is chosen only when the benefits outweigh the costs.

High Energy Consumption

The combination of freezing, maintaining a strong vacuum, and then condensing the water vapor is an extremely energy-intensive process. It is far more costly than simple heat-based drying.

Significant Capital Costs

The equipment required—known as a freeze dryer or lyophilizer—is complex and expensive. It includes refrigeration systems, powerful vacuum pumps, and condenser units, representing a major investment.

A Slow and Deliberate Process

A typical freeze-drying cycle can take anywhere from 24 to 72 hours, or even longer for some pharmaceutical products. This low throughput makes it unsuitable for many high-volume, low-margin goods.

How to Interpret These Terms in Practice

Your understanding of the terms should be guided entirely by the context in which you find them.

- If your context is food production or consumer goods: You will almost exclusively see and use the term freeze drying.

- If your context is a laboratory, biotech, or pharmaceutical setting: The standard and expected term is lyophilization.

- If you are a student or general consumer: Recognize that the terms are interchangeable and use the context to understand whether the application is for preserving food or a sensitive biological material.

Ultimately, knowing both terms gives you a clearer picture of how this powerful preservation technology is applied across different industries.

Summary Table:

| Feature | Freeze Drying / Lyophilization |

|---|---|

| Core Process | Identical three-step dehydration via sublimation |

| Primary Industry | Food processing (Freeze Drying) |

| Key Benefit | Preserves structure, flavor, and biological activity |

| Main Challenge | High energy consumption, cost, and long cycle times |

Ready to enhance your lab's preservation capabilities?

Whether you refer to it as freeze drying or lyophilization, the right equipment is critical for success. KINTEK specializes in high-performance lab equipment, including reliable freeze dryers/lyophilizers, designed to meet the rigorous demands of pharmaceutical, biotech, and research laboratories.

Our solutions help you preserve sensitive materials with precision and efficiency. Contact our experts today to find the perfect system for your specific application and ensure the integrity of your most valuable samples.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

- Small Injection Molding Machine for Lab Use

People Also Ask

- What property determines evaporation rate? Control heat, pressure, and surface area for optimal results.

- How does freeze drying extend the shelf life of pharmaceutical products? Preserve Potency and Stability for Years

- What are the factors affecting evaporation? Control the Rate of Any Liquid's Vaporization

- What properties are involved in evaporation? Master the Key Factors for Efficient Drying

- Why is freeze drying considered more effective than ordinary drying? Preserve Structure, Nutrients & Flavor