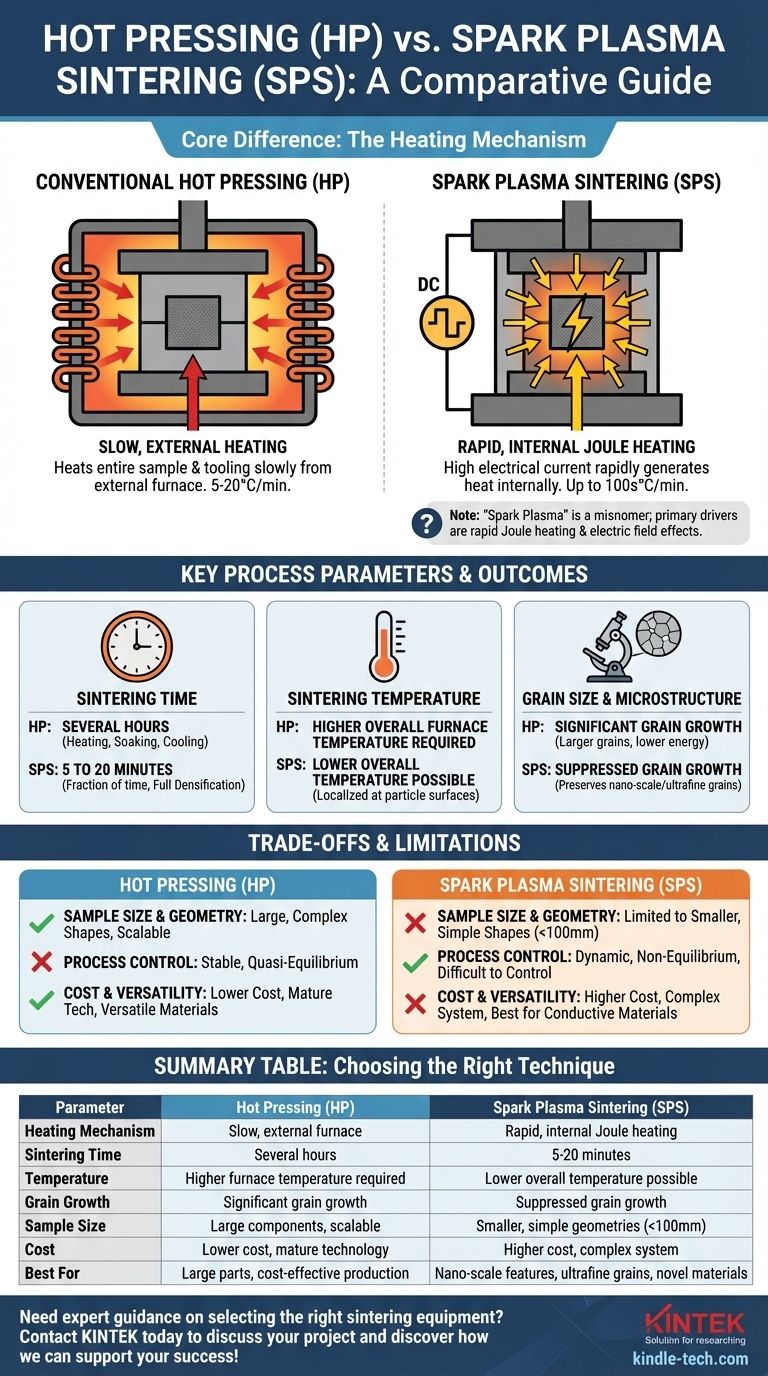

At its core, the difference between conventional hot pressing (HP) and spark plasma sintering (SPS) is the heating mechanism. Hot pressing slowly heats the entire sample and its tooling from an external furnace, while SPS uses a high electrical current to rapidly generate heat internally within the tooling and, in many cases, the sample itself. This fundamental difference in heat delivery drives all other distinctions in speed, temperature, and final material properties.

While both are powder metallurgy techniques that use uniaxial pressure and heat to create dense solids, SPS leverages rapid, internal Joule heating to achieve densification in minutes, preserving fine microstructures. Conventional hot pressing is a slower, bulk heating process better suited for larger components where microstructural control is less critical.

The Core Mechanism: How Heat is Delivered

Understanding how energy is introduced into the system is the key to differentiating these two processes.

Conventional Hot Pressing (HP): Slow, External Heating

A hot press operates much like a sophisticated oven combined with a hydraulic press. The powder-filled die assembly is placed inside a furnace.

Heating elements (resistive or induction) located outside the die assembly gradually heat the chamber. This heat then slowly transfers via radiation and conduction to the die, the punches, and finally, the powder compact. This entire process is slow, with heating rates typically in the range of 5-20°C per minute.

Spark Plasma Sintering (SPS): Rapid, Internal Heating

SPS, also known as Field-Assisted Sintering Technology (FAST), employs a radically different approach. It uses the tooling itself as a heating element.

A high-power, pulsed DC current is passed directly through the conductive die (usually graphite) and the punches. This generates intense, rapid Joule heating due to electrical resistance. If the powder sample is conductive, the current will also pass through it, creating localized superheating at the contact points between particles.

This internal heating results in incredibly fast heating rates, often exceeding several hundred degrees Celsius per minute. The term "spark plasma" is a commercial misnomer; while localized plasma may form between particles, the primary drivers for enhanced sintering are rapid heating and electric field effects.

Comparing Key Process Parameters

The different heating methods lead to dramatic variations in the process itself.

Sintering Time

This is the most significant practical difference. A typical hot press cycle, including heating, soaking at temperature, and cooling, can take several hours.

An SPS cycle achieves full densification in a fraction of that time, with total process times often lasting only 5 to 20 minutes.

Sintering Temperature

Because SPS heating is so efficient and localized at the particle surfaces where sintering occurs, it can often achieve full density at a lower overall furnace temperature compared to hot pressing. The energy is delivered precisely where it's needed most.

Hot pressing requires a higher furnace temperature for a longer time to ensure the entire bulk sample reaches the necessary sintering temperature.

Grain Size and Microstructure

The long duration at high temperatures during hot pressing inevitably leads to significant grain growth. This is a natural process where smaller grains are consumed by larger ones to reduce total grain boundary energy.

The extreme speed of the SPS cycle is its greatest advantage for materials science. By minimizing the time the material spends at high temperature, SPS effectively suppresses grain growth, making it possible to produce fully dense materials with nano-scale or ultra-fine-grained microstructures.

Understanding the Trade-offs and Limitations

SPS is a powerful technology, but it is not a universal replacement for hot pressing. Each has distinct advantages and disadvantages.

Sample Size and Geometry

Hot pressing is highly scalable. It is routinely used to produce large components (many inches or even feet in diameter) and can be adapted for relatively complex shapes.

SPS is generally limited to producing smaller, simple geometries, such as discs or squares, typically under 100 mm in diameter. Ensuring uniform current density and temperature distribution becomes extremely difficult in larger or more complex parts.

Cost and Versatility

Conventional hot presses are a mature, robust technology. They are less expensive to purchase, operate, and maintain than their SPS counterparts. They are also highly versatile and can be used for a vast range of materials, including polymers, metals, and ceramics.

SPS systems are significantly more expensive and complex. They work best with conductive graphite tooling and perform optimally when sintering conductive or semi-conductive materials. While insulators can be sintered, it requires special techniques that negate some of the direct heating benefits.

Process Control

Hot pressing is a stable, quasi-equilibrium process that is relatively straightforward to control.

SPS is a dynamic, non-equilibrium process. The extreme heating rates and temperature gradients can be difficult to measure and control accurately, sometimes leading to "hot spots" or thermal runaway, especially with reactive materials.

Making the Right Choice for Your Goal

Selecting the correct technique requires a clear understanding of your primary objective, whether it is research novelty, production scale, or material performance.

- If your primary focus is preserving nano-scale features or creating ultra-fine-grained materials: SPS is the superior choice due to its ability to consolidate powders rapidly while suppressing grain growth.

- If your primary focus is producing large components or cost-effective manufacturing: Conventional hot pressing is the more practical and scalable solution.

- If your primary focus is researching novel, non-equilibrium, or metastable material phases: SPS is a powerful discovery tool, as its rapid cycle can "lock in" unique microstructures that would not survive a slow thermal process.

- If your primary focus is established production with a wide variety of materials, including insulators: Hot pressing offers greater versatility and a more established, lower-cost technology base.

Ultimately, your choice is a strategic one, balancing the priorities of microstructural fidelity and speed against those of scalability and cost.

Summary Table:

| Parameter | Hot Pressing (HP) | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heating Mechanism | Slow, external furnace heating | Rapid, internal Joule heating via pulsed DC current |

| Sintering Time | Several hours | 5 to 20 minutes |

| Temperature | Higher furnace temperature required | Lower overall temperature possible |

| Grain Growth | Significant grain growth | Suppressed grain growth |

| Sample Size | Large components, scalable | Smaller, simple geometries (typically <100mm) |

| Cost | Lower cost, mature technology | Higher cost, complex system |

| Best For | Large parts, cost-effective production, versatile materials | Nano-scale features, ultrafine grains, novel materials |

Need expert guidance on selecting the right sintering equipment for your research or production goals? At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's unique needs. Whether you're exploring novel materials with SPS or scaling up production with hot pressing, our team can help you choose the perfect solution to achieve superior material properties and efficiency. Contact us today to discuss your project and discover how KINTEK can support your success!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What role does axial pressure play during vacuum hot pressing of Lithium Niobate? Optimize Density & Grain Size

- How does the pressure control system of a Vacuum Hot Press furnace influence TiAl4822/Ti6Al4V solid-solid reactions?

- What is gas pressure sintering? Achieve Near-Perfect Density for High-Performance Materials

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity

- Which core process conditions does a vacuum hot pressing sintering furnace provide for ZrB2-SiC layered ceramics?

- What is the function of the hot pressing process in TlBr detector manufacturing? Optimize Crystal Density & Resolution

- What effect does a high-vacuum environment in a hot-press furnace have on Mo-Na alloys? Achieve Pure Microstructures

- What role does a vacuum hot pressing furnace play in Ti-6Al-7Nb production? Achieve 99%+ Density and Pure Microstructure