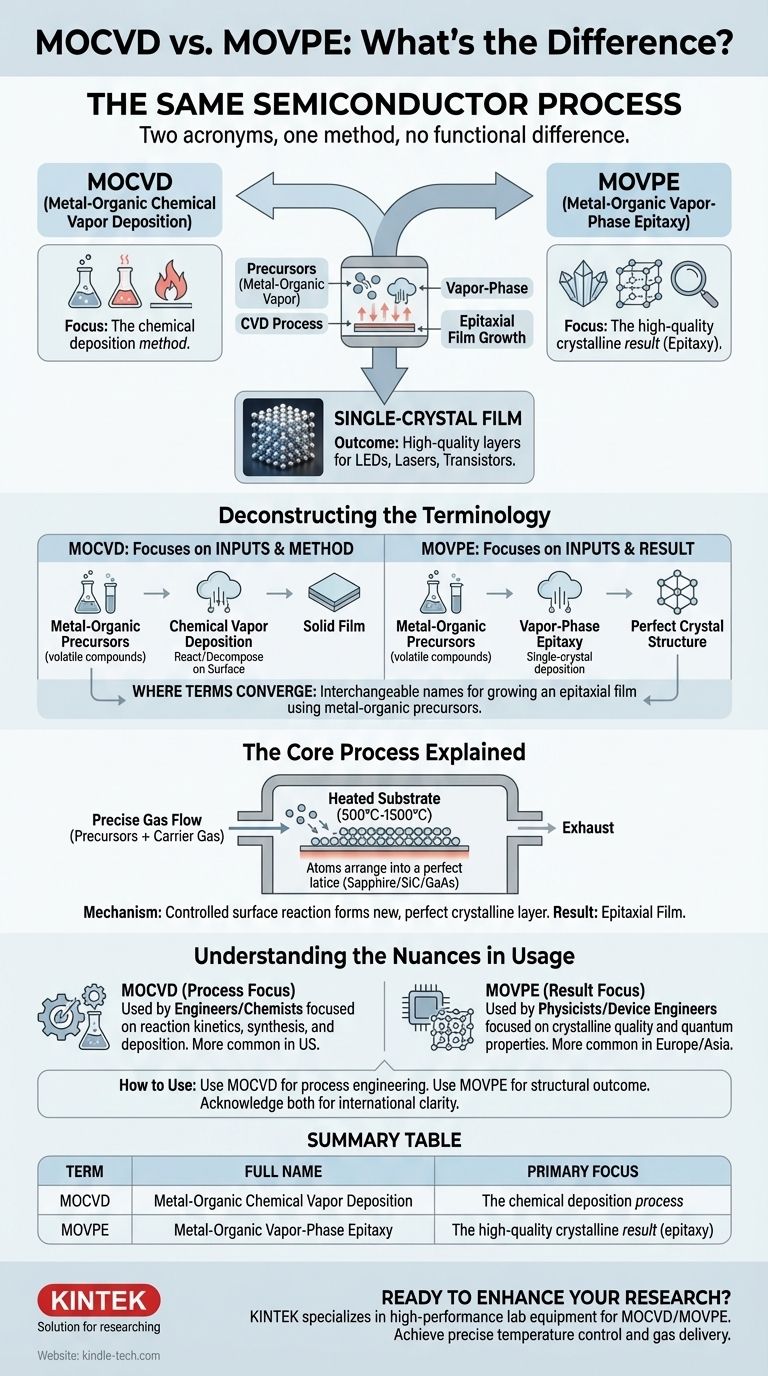

In practice, there is no functional difference between MOCVD and MOVPE. They are two acronyms that describe the exact same semiconductor manufacturing process. The choice between them is a matter of terminology and emphasis, not a reflection of a different technique, hardware, or outcome.

The core takeaway is that MOCVD (Metal-Organic Chemical Vapor Deposition) and MOVPE (Metal-Organic Vapor-Phase Epitaxy) are interchangeable names for a single process. MOCVD emphasizes the chemical deposition method, while MOVPE emphasizes the creation of a high-quality crystal structure (epitaxy) as the result.

Deconstructing the Terminology

To understand why these terms are synonymous, it's best to break down what each acronym stands for. The confusion arises from describing the same activity from two slightly different perspectives: the process and the result.

MOCVD: Metal-Organic Chemical Vapor Deposition

This term focuses on the inputs and the method.

- Metal-Organic: This refers to the precursor materials—compounds where metal atoms are bonded to organic molecules. These precursors are volatile, allowing them to be transported as a vapor.

- Chemical Vapor Deposition (CVD): This is a broad category of processes where a substrate is exposed to volatile precursors, which react or decompose on the substrate's surface to produce a high-quality solid film.

MOVPE: Metal-Organic Vapor-Phase Epitaxy

This term focuses on the inputs and the result.

- Metal-Organic: This is identical to its meaning in MOCVD, referring to the precursor materials.

- Vapor-Phase Epitaxy (VPE): This is a more specific term. "Epitaxy" refers to the deposition of a single-crystal film on a single-crystal substrate, where the new layer adopts the crystal structure of the substrate. "Vapor-Phase" simply means the materials are delivered as a gas or vapor.

Where the Terms Converge

When you use metal-organic precursors in a chemical vapor deposition process specifically to grow an epitaxial (single-crystal) film, you are, by definition, performing both MOCVD and MOVPE. The terms become interchangeable because one describes the general action (CVD) while the other describes the specific, high-quality outcome (Epitaxy) of that same action.

The Core Process Explained

Regardless of the name used, the underlying technology is a highly controlled method for growing crystalline layers, critical for manufacturing LEDs, lasers, and high-performance transistors.

The Mechanism

The process involves introducing precise amounts of metal-organic precursor gases, along with other gases, into a reaction chamber. These gases flow over a heated substrate, which is typically a wafer of a material like sapphire, silicon carbide, or gallium arsenide.

Surface Chemistry

The high temperature of the substrate (often between 500°C and 1500°C) provides the energy needed to break down the precursor molecules. The metal atoms then deposit onto the surface atom by atom, arranging themselves to match the crystal lattice of the substrate, forming a new, perfect crystalline layer.

The Result: An Epitaxial Film

This highly controlled deposition results in an extremely high-quality film with very few defects. This crystalline perfection, or "epitaxy," is essential for the performance of modern electronic and optoelectronic devices.

Understanding the Nuances in Usage

While the technology is identical, the choice of acronym can sometimes signal a subtle difference in focus or community.

Focus on Process vs. Result

Engineers or chemists focused on the reaction kinetics, precursor synthesis, and the deposition process itself may prefer the term MOCVD. It accurately describes the chemical method being employed.

Physicists or device engineers who are most concerned with the crystalline quality, electronic properties, and quantum structure of the final film may prefer MOVPE. It emphasizes the all-important epitaxial nature of the grown layers.

Regional and Historical Factors

The preference for one term over the other can also be a matter of regional convention. For decades, "MOVPE" has been more common in Europe and parts of Asia, while "MOCVD" has been more prevalent in the United States. However, with the global nature of science and industry, this distinction has become increasingly blurred.

How to Use These Terms Correctly

Ultimately, choosing the right term is about communicating clearly with your audience. Both are correct, but one may be better suited depending on your context.

- If your primary focus is the chemical reaction or deposition method: Using MOCVD is precise and centers the conversation on the process engineering.

- If your primary focus is the single-crystal quality of the final device layers: Using MOVPE is more descriptive of the structural outcome that enables device performance.

- If you are communicating with a broad or international audience: It is often best to acknowledge both terms, for instance, by writing "MOCVD (also known as MOVPE)," to ensure maximum clarity.

Focusing on the underlying principles of the growth process is far more important than getting caught up in the acronyms used to describe it.

Summary Table:

| Term | Full Name | Primary Focus |

|---|---|---|

| MOCVD | Metal-Organic Chemical Vapor Deposition | The chemical deposition process |

| MOVPE | Metal-Organic Vapor-Phase Epitaxy | The high-quality crystalline result (epitaxy) |

Ready to Enhance Your Semiconductor Research?

Understanding the precise terminology is the first step. The next is equipping your lab with the right technology to achieve superior epitaxial growth.

KINTEK specializes in providing high-performance lab equipment and consumables tailored for advanced semiconductor manufacturing processes like MOCVD/MOVPE. We help laboratories like yours achieve the precise temperature control and gas delivery required for growing high-quality, single-crystal films for LEDs, lasers, and high-performance transistors.

Contact us today to discuss how our solutions can meet your specific laboratory needs and drive your research forward.

Get in Touch for a Consultation

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond for Thermal Management Applications

People Also Ask

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the frequency of MPCVD? A Guide to Choosing 2.45 GHz vs. 915 MHz for Your Application

- What is MP CVD? Unlock the Power of Microwave Plasma for High-Purity Diamond Synthesis

- What is the microwave plasma enhanced chemical vapor deposition process? Achieve Low-Temperature, High-Quality Coatings

- What are the primary advantages of the CVD method for growing diamonds? Engineering High-Purity Gems and Components