At its core, microwave plasma is a highly energetic state of matter created by using microwave radiation to ionize a gas. Its unique properties make it indispensable for advanced industrial processes, including the synthesis of artificial diamonds, manufacturing next-generation semiconductors, and environmental remediation.

The critical advantage of microwave plasma is its electrodeless nature, which prevents contamination and allows for the creation of extremely high-purity, high-density plasmas. This combination is why it is the technology of choice for the most demanding material science and fabrication applications.

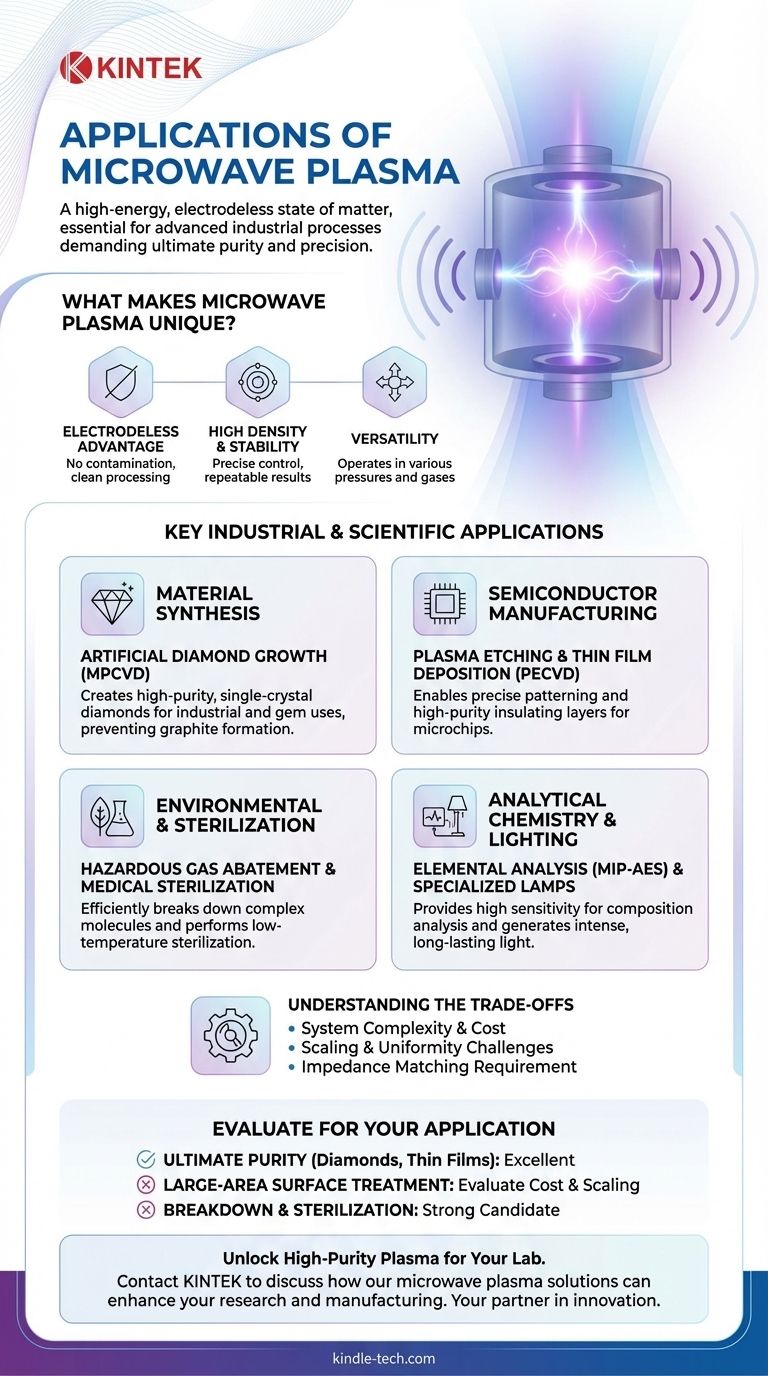

What Makes Microwave Plasma Unique?

To understand its applications, we must first understand why microwave plasma is fundamentally different from other plasma generation methods, such as DC (direct current) or RF (radio frequency). The advantages stem directly from how the energy is delivered to the gas.

The Electrodeless Advantage

In many plasma systems, metal electrodes are placed directly inside the chamber to deliver electrical power. These electrodes erode over time, releasing contaminants into the plasma and onto the material you are processing.

Microwave plasma is electrodeless. The energy is coupled into the gas via electromagnetic waves from outside the reaction chamber, completely eliminating this source of contamination. This is the single most important factor for applications demanding ultimate purity.

High Plasma Density and Stability

Microwaves, typically at a frequency of 2.45 GHz, are exceptionally efficient at transferring energy to the electrons in a gas. This creates a much higher density of ions and reactive species compared to other methods at similar pressures.

This high-density plasma is also very stable, allowing for precise and repeatable control over processing conditions, which is essential for industrial manufacturing.

Versatility in Operating Conditions

Microwave plasma systems can be engineered to operate across a vast range of pressures, from high vacuum to atmospheric pressure. They can also sustain a plasma in virtually any type of gas, including noble gases, reactive gases, and complex molecular mixtures.

Key Industrial and Scientific Applications

The unique properties of microwave plasma make it the ideal solution for several high-value, high-technology fields.

Material Synthesis: The Case of Artificial Diamonds

The creation of high-quality, single-crystal diamonds is the flagship application of Microwave Plasma-Assisted Chemical Vapor Deposition (MPCVD).

A gas mixture, typically methane in hydrogen, is ionized. The high-density microwave plasma efficiently breaks apart the methane and hydrogen molecules, creating a precise concentration of carbon radicals and atomic hydrogen. This environment is perfect for growing gem-quality diamond crystals, layer by layer, on a seed crystal. The electrodeless nature is non-negotiable here to prevent the formation of black, graphite-like carbon.

Semiconductor Manufacturing: Etching and Deposition

In fabricating microchips, microwave plasma is used for two critical steps:

- Plasma Etching: The high density of reactive ions allows for the precise, anisotropic (directional) etching of microscopic patterns onto silicon wafers. This is fundamental to creating the complex circuitry of a modern processor.

- Thin Film Deposition (PECVD): It's also used to deposit high-purity thin films, such as silicon nitride or silicon dioxide, which act as insulators or protective layers on the chip.

Environmental and Sterilization Uses

The ability to generate a high density of reactive chemical species makes microwave plasma a powerful tool for breaking down unwanted molecules.

This is used for abatement of hazardous gases, such as perfluorocarbons (PFCs) released during semiconductor manufacturing. It is also used for low-temperature sterilization of heat-sensitive medical equipment, as the plasma's reactive species can kill microbes without high heat.

Analytical Chemistry and Lighting

In analytical instruments, Inductively Coupled Plasma (ICP) often uses RF, but Microwave Induced Plasma (MIP) is a powerful alternative for Atomic Emission Spectrometry (AES). It is used to analyze the elemental composition of a sample with high sensitivity.

Furthermore, its high efficiency in generating light has led to its use in highly specialized, long-lasting sulfur lamps and other sources for intense UV or visible light.

Understanding the Trade-offs

No technology is a universal solution. While powerful, microwave plasma has specific complexities that must be considered.

System Complexity and Cost

Microwave plasma systems involve sophisticated components, including a microwave generator (magnetron or solid-state), waveguides to direct the energy, and a specially designed applicator or reactor. This generally makes them more complex and expensive to purchase and maintain than simpler DC plasma setups.

Challenges in Scaling and Uniformity

Achieving a perfectly uniform plasma over a very large area can be difficult. The wavelength of the microwaves (about 12 cm for the common 2.45 GHz frequency) can create standing waves inside the chamber, leading to "hot spots" where the plasma is denser. Designing reactors for large-area uniformity is a significant engineering challenge.

The Need for Impedance Matching

For the system to work efficiently, the impedance of the microwave generator must be matched to the impedance of the plasma. Because the plasma's properties change with pressure and gas type, this often requires a complex automatic or manual impedance matching system to prevent power from being reflected back to the source.

How to Evaluate Microwave Plasma for Your Application

Choosing the right plasma source depends entirely on your primary technical and business goals.

- If your primary focus is ultimate purity and high-value material synthesis (e.g., diamonds, specific thin films): Microwave plasma is often the superior choice, as its electrodeless and high-density nature is perfectly suited for these tasks.

- If your primary focus is large-area surface treatment or cost-sensitive applications: You must carefully evaluate the scalability and cost trade-offs against other methods like large-area RF or atmospheric plasma systems.

- If your primary focus is breaking down difficult chemical compounds or achieving effective sterilization: The high density of reactive species generated by microwave plasma makes it a very strong candidate worth investigating.

By understanding these core principles, you can select the right plasma technology based on the fundamental requirements of your goal.

Summary Table:

| Application Area | Key Use Case | Primary Advantage |

|---|---|---|

| Material Synthesis | Artificial Diamond Growth (MPCVD) | Ultimate Purity, High-Density Plasma |

| Semiconductor Manufacturing | Plasma Etching & Thin Film Deposition (PECVD) | Precise, Contamination-Free Processing |

| Environmental & Medical | Hazardous Gas Abatement & Sterilization | Efficient Breakdown of Complex Molecules |

| Analytical & Lighting | Elemental Analysis (MIP-AES), Specialized Lamps | High Sensitivity & Efficiency |

Unlock the Power of High-Purity Plasma for Your Lab

Are you working on advanced material synthesis, semiconductor R&D, or other high-precision processes that demand contamination-free plasma? KINTEK specializes in advanced lab equipment, including microwave plasma systems, to meet your most demanding requirements.

Contact our experts today to discuss how our solutions can enhance your research and manufacturing outcomes. Let KINTEK be your partner in innovation.

Visual Guide

Related Products

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond for Thermal Management Applications

People Also Ask

- What is the frequency of MPCVD? A Guide to Choosing 2.45 GHz vs. 915 MHz for Your Application

- What is the function of a Microwave PECVD system for Diamond Nanospikes? Precision 1-Step Nanostructure Synthesis

- How does a microwave plasma reactor facilitate the synthesis of diamond? Master MPCVD with Precision Technology

- What is MP CVD? Unlock the Power of Microwave Plasma for High-Purity Diamond Synthesis

- What are the primary advantages of the CVD method for growing diamonds? Engineering High-Purity Gems and Components