Deposition temperature is the primary control knob for determining the fundamental structure and properties of a thin film. In any deposition process, from sputtering to chemical vapor deposition, temperature governs the energy available to atoms as they arrive on the substrate. This energy dictates their ability to move, find optimal positions, and ultimately form a film with specific characteristics like crystallinity, density, and adhesion.

The core effect of deposition temperature is its control over adatom surface mobility. Increasing the temperature gives arriving atoms more energy to move across the surface, allowing them to arrange into a more ordered, dense, and stable film structure.

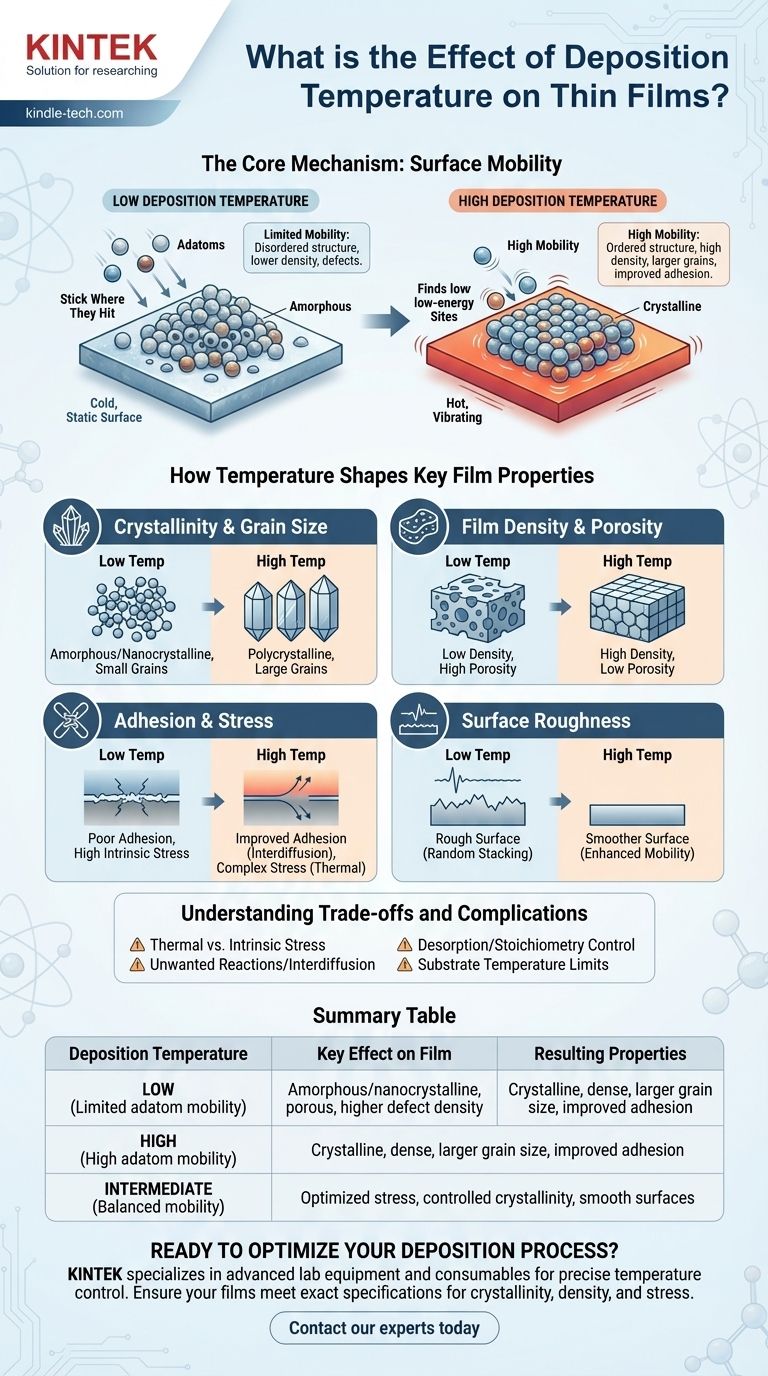

The Core Mechanism: Surface Mobility

The behavior of a thin film is determined at the atomic level the moment atoms land on the surface. Temperature is the dominant factor influencing this behavior.

What is an Adatom?

An adatom is an atom that has landed, or "adsorbed," onto a surface but has not yet chemically bonded or settled into the bulk crystal lattice. Its short-lived existence is the most critical phase of film growth.

How Temperature Fuels Mobility

Think of adatoms as marbles dropped onto a bumpy surface. At low temperatures, the surface is "still," and the marbles stick wherever they land, creating a random, porous pile.

As you increase the temperature, you are essentially "vibrating" the surface. This energy allows the marbles—our adatoms—to jiggle and roll around, finding lower spots and fitting together more tightly. This movement is surface mobility.

The Impact of Insufficient Mobility

At low deposition temperatures, adatoms have very little kinetic energy. They effectively "stick where they hit."

This leads to a disordered structure that is often amorphous (lacking a crystal lattice) or nanocrystalline. The film will likely be less dense, more porous, and contain more defects because atoms did not have the energy to arrange themselves efficiently.

The Impact of High Mobility

At higher deposition temperatures, adatoms are highly mobile. They can diffuse significant distances across the surface before losing their energy.

This allows them to find and settle into low-energy sites within a growing crystal lattice. The result is a film with larger grain sizes, higher crystallinity, and greater density.

How Temperature Shapes Key Film Properties

By controlling surface mobility, temperature directly influences the most important measurable properties of the final film.

Crystallinity and Grain Size

This is the most direct consequence. Low temperatures freeze atoms in a disordered state, creating amorphous films. As temperature increases, mobility allows for the formation of small crystals (nanocrystalline), then larger, more defined crystals (polycrystalline).

Film Density and Porosity

Higher mobility allows adatoms to move into valleys and fill microscopic voids between growing crystal columns. This results in a much denser film with lower porosity, which is critical for applications like barrier layers or high-quality optical coatings.

Adhesion to the Substrate

Generally, higher temperatures improve film adhesion. The increased energy promotes interdiffusion at the film-substrate interface, creating a graded, stronger bond rather than an abrupt junction. It can also help bake off surface contaminants prior to film nucleation.

Film Stress

Deposition temperature has a complex effect on film stress. It can help reduce intrinsic stress (stress from the growth process) by allowing atoms to settle into relaxed lattice positions. However, it increases thermal stress, which arises from the mismatch in thermal expansion coefficients between the film and substrate as they cool down.

Surface Roughness

The relationship is not always linear. At very low temperatures, random stacking of atoms can create a rough surface. As temperature increases, enhanced mobility allows atoms to fill valleys, smoothing the film. At very high temperatures, however, atoms may preferentially form distinct 3D islands, which can increase roughness again.

Understanding the Trade-offs and Complications

While higher temperatures often sound better, they introduce significant challenges that must be managed. The "best" temperature is always a compromise.

Intrinsic vs. Thermal Stress

Optimizing for low stress is a balancing act. A temperature high enough to anneal out intrinsic growth stresses might be so high that the thermal stress generated upon cooling causes the film to crack or delaminate.

Unwanted Reactions and Interdiffusion

High temperatures can be destructive. They can cause the deposited film to react with the substrate, forming an unintended interfacial layer (e.g., a silicide). This can ruin the performance of an electronic or optical device.

Desorption and Stoichiometry Control

In compound material deposition (e.g., an oxide or nitride), very high temperatures can give some elements enough energy to "boil off" or desorb from the surface. This can lead to a film that is off-stoichiometry and lacks the desired chemical composition and properties.

Substrate Limitations

Perhaps the most practical limitation is the substrate itself. You cannot deposit a film at 800°C on a polymer substrate that melts at 200°C. The maximum allowable temperature is often dictated by the thermal stability of what you are coating.

Choosing the Right Temperature for Your Goal

The ideal deposition temperature is not a single value but is instead tied directly to the desired outcome of your film.

- If your primary focus is maximum crystallinity and density (e.g., optical coatings, semiconductor layers): Aim for a higher deposition temperature (typically 30-50% of the coating material's melting point in Kelvin), carefully managing the resulting thermal stress.

- If your primary focus is creating an amorphous film (e.g., diffusion barriers): Use the lowest practical temperature, often with substrate cooling, to quench adatoms in place and prevent crystallization.

- If your primary focus is coating a temperature-sensitive substrate (e.g., plastics, organic electronics): You are forced to use low temperatures and may need to introduce other energy sources (like ion bombardment) to compensate for the lack of thermal mobility.

- If your primary focus is minimizing total film stress: This requires careful experimentation to find an intermediate "sweet spot" where intrinsic stress is relaxed and thermal stress has not yet become dominant.

By treating temperature as a precise tool to control atomic mobility, you gain direct command over your material's final structure and performance.

Summary Table:

| Deposition Temperature | Key Effect on Film | Resulting Properties |

|---|---|---|

| Low | Limited adatom mobility | Amorphous/nanocrystalline, porous, higher defect density |

| High | High adatom mobility | Crystalline, dense, larger grain size, improved adhesion |

| Intermediate | Balanced mobility | Optimized stress, controlled crystallinity, smooth surfaces |

Ready to Optimize Your Deposition Process?

Achieving the perfect thin film requires precise control over deposition temperature. Whether you're developing optical coatings, semiconductor layers, or coatings for temperature-sensitive substrates, the right equipment is critical.

KINTEK specializes in advanced lab equipment and consumables for all your deposition needs. Our expertise can help you select the right system to precisely control temperature and other parameters, ensuring your films meet exact specifications for crystallinity, density, and stress.

Contact our experts today to discuss how we can support your laboratory's thin film research and production goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs