In response to pressure, graphene demonstrates extraordinary resilience due to its unique, one-atom-thick honeycomb lattice of carbon atoms. It is the strongest material ever measured, capable of withstanding immense force before any structural failure. However, this pressure is not just a test of its strength; it also serves as a mechanism to controllably alter its unique electronic and thermal properties.

The crucial takeaway is that graphene's response to pressure is a duality: it exhibits world-record strength against fracture while also allowing its fundamental electrical characteristics to be intentionally tuned by mechanical strain.

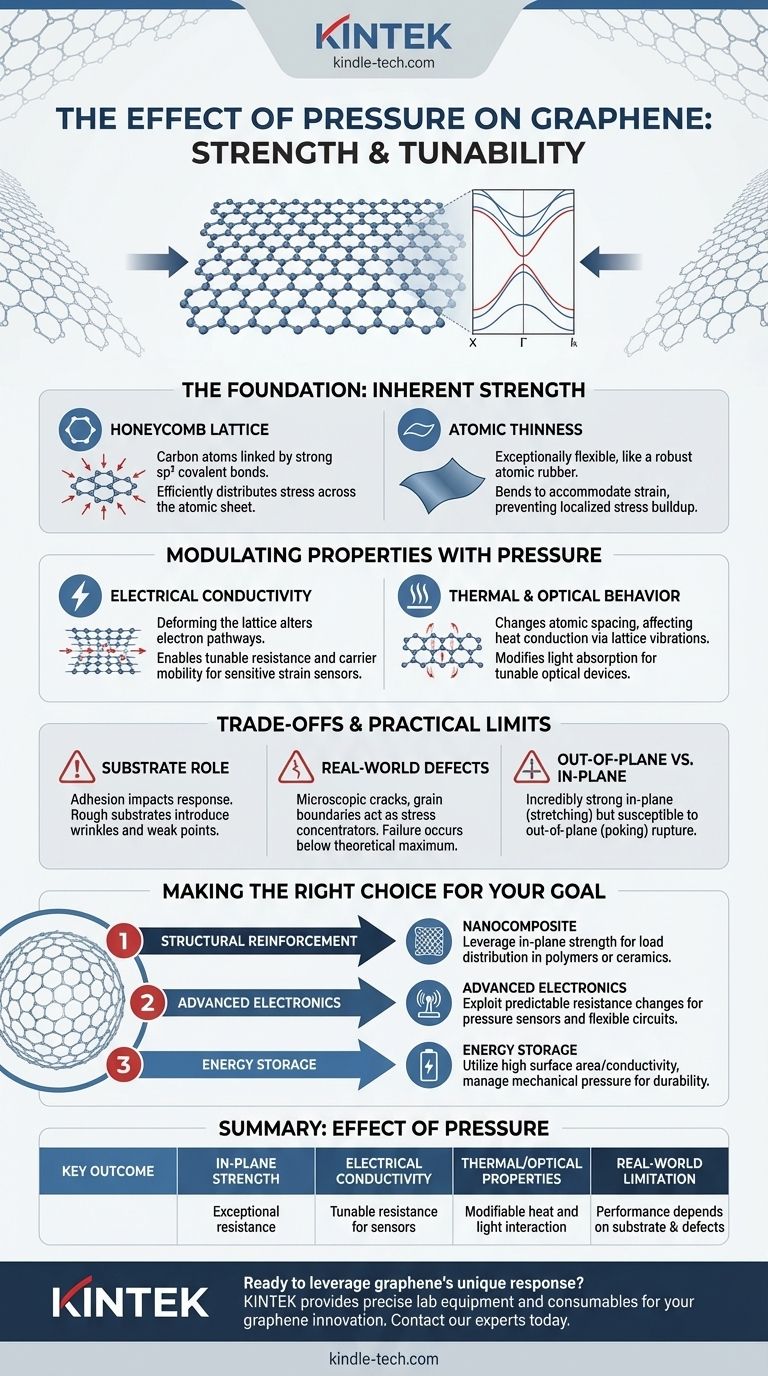

The Foundation: Graphene's Inherent Strength

Graphene's ability to withstand pressure is not magic; it is a direct result of its atomic structure. This understanding is the first step to harnessing its capabilities.

The Power of the Honeycomb Lattice

The carbon atoms in graphene are linked by sp² covalent bonds, among the strongest chemical bonds in nature. These bonds form a hexagonal, honeycomb-like pattern.

This structure is incredibly efficient at distributing mechanical force. When pressure is applied, the stress is spread evenly across the entire atomic sheet rather than concentrating at a single point.

The Advantage of Atomic Thinness

As a true two-dimensional material, graphene is exceptionally flexible. It can bend and stretch to accommodate strain without breaking, much like a sheet of rubber, but with vastly superior strength.

This flexibility prevents the buildup of localized stress that would cause a thicker, more rigid material to crack and fail.

How Pressure Modulates Graphene's Properties

Applying pressure does more than just test graphene's limits. The resulting mechanical strain—the stretching or compressing of the atomic lattice—directly changes how the material behaves.

Impact on Electrical Conductivity

Graphene's high electrical conductivity is one of its most famous properties. This is due to the unique way electrons move through its perfect lattice.

When pressure deforms this lattice, it can alter the pathways for these electrons, thereby changing the material's resistance or carrier mobility. This effect is the foundational principle behind graphene-based strain and pressure sensors.

Shifting Thermal and Optical Behavior

The vibrations of the atomic lattice govern how graphene conducts heat. Applying pressure changes the spacing between atoms, which can affect these vibrations and thus its thermal conductivity.

Similarly, straining the material can subtly modify how it absorbs and interacts with light, opening possibilities for tunable optical devices.

Understanding the Trade-offs and Practical Limits

While theoretically pristine graphene is immensely strong, its real-world performance under pressure is influenced by several critical factors. Objectivity requires acknowledging these limitations.

The Critical Role of the Substrate

In most applications, graphene is not free-floating; it is placed on a substrate. The adhesion between the graphene and the substrate can significantly impact its response to pressure.

A rough or poorly chosen substrate can introduce wrinkles or defects, creating weak points that can lead to premature failure under stress.

The Reality of Defects

Real-world graphene produced at an industrial scale is never perfectly homogenous. Microscopic cracks, grain boundaries, or missing atoms can act as stress concentrators.

These imperfections mean that a large sheet of graphene will typically fail at pressures far below its theoretical maximum strength. They are the weakest link in the chain.

Out-of-Plane vs. In-Plane Force

Graphene is incredibly strong when force is applied in-plane (stretching it). However, it is much more susceptible to out-of-plane force (poking it), where it can be more easily ruptured, especially in the presence of sharp objects.

Making the Right Choice for Your Goal

Your application determines which aspect of graphene's response to pressure is most important.

- If your primary focus is structural reinforcement: Leverage graphene's immense in-plane tensile strength by embedding it as a nanocomposite to distribute load and prevent fracture in materials like polymers or ceramics.

- If your primary focus is advanced electronics: Exploit the predictable changes in electrical resistance under strain to design highly sensitive and durable pressure sensors, flexible circuits, or wearable devices.

- If your primary focus is energy storage: Utilize its high surface area and conductivity, recognizing that the mechanical pressure within a battery or supercapacitor during charge cycles must be managed to ensure long-term durability.

By understanding how graphene behaves under pressure, you can move from appreciating its strength to strategically engineering its response for your specific purpose.

Summary Table:

| Effect of Pressure on Graphene | Key Outcome |

|---|---|

| In-Plane Strength | Exceptional resistance to stretching and fracture |

| Electrical Conductivity | Tunable resistance for sensors and flexible electronics |

| Thermal/Optical Properties | Modifiable heat and light interaction |

| Real-World Limitation | Performance depends on substrate quality and defects |

Ready to leverage graphene's unique response to pressure in your lab?

KINTEK specializes in providing the precise lab equipment and consumables needed to research, test, and apply graphene's tunable properties—from strain sensors to reinforced composites. Our expertise ensures you get the right tools for your specific application, whether you're developing next-generation electronics or durable materials.

Contact our experts today to discuss how we can support your graphene innovation.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability