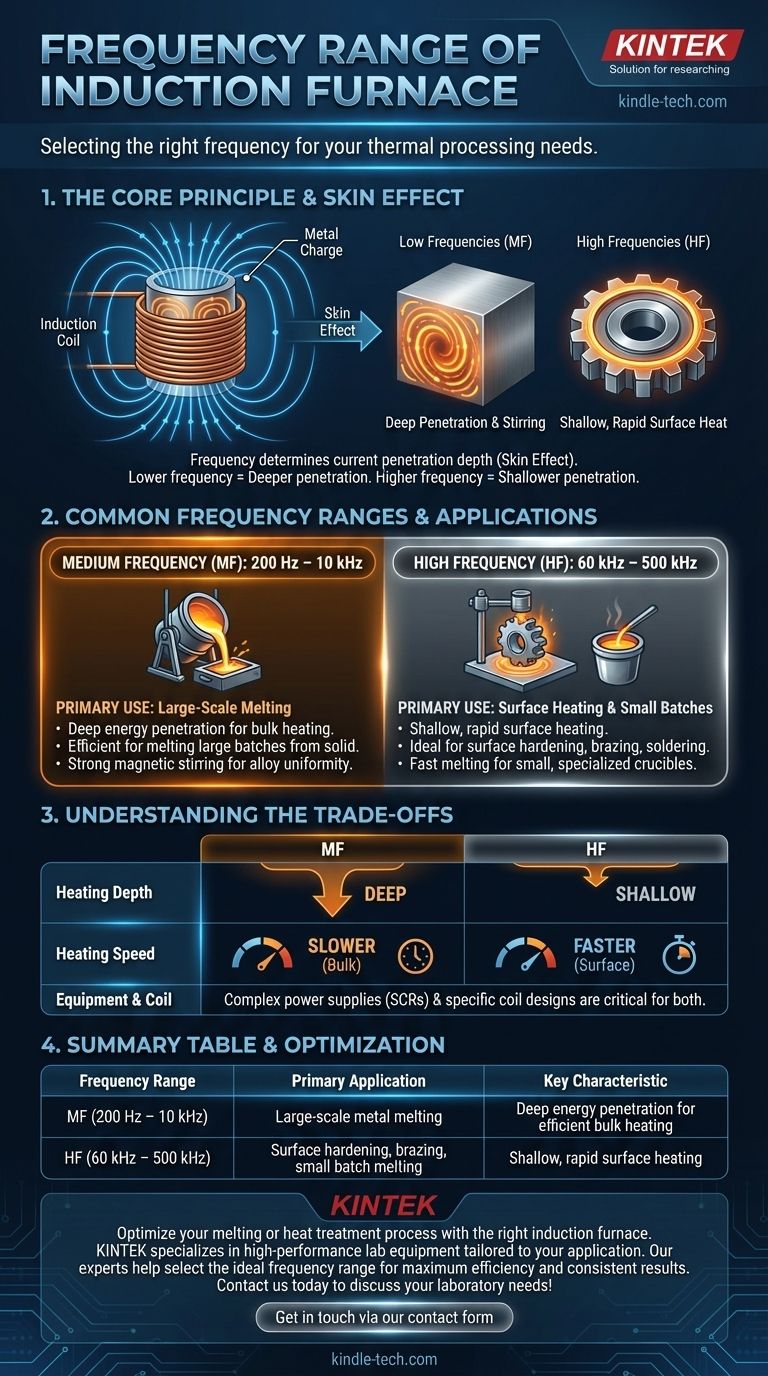

The frequency of an induction furnace is not a single value but falls into distinct ranges based on its intended application. Furnaces designed for large-scale melting operate in the medium frequency (MF) range, typically from 200 Hz to 10 kHz. In contrast, systems used for surface heating or smaller, more precise melting tasks operate in the high frequency (HF) range, which can span from 60 kHz to 500 kHz.

The choice of frequency is a critical engineering decision that dictates the furnace's primary function. Lower frequencies penetrate metal more deeply for melting large volumes, while higher frequencies concentrate energy near the surface for rapid heating or treating smaller batches.

Why Frequency Is the Decisive Factor

To understand the different frequency ranges, we must first understand the core principle of induction heating and how frequency directly controls its behavior.

The Principle of Induction Heating

An induction furnace operates like a transformer. A primary coil, powered by an alternating current, generates a powerful, rapidly changing magnetic field. The metal to be heated (the "charge") is placed within this field, effectively becoming a secondary coil.

This magnetic field induces powerful electrical currents, known as eddy currents, to flow within the metal. The metal's natural resistance to the flow of these eddy currents generates immense heat, causing it to melt.

The Critical "Skin Effect"

The operating frequency of the power supply directly determines how deeply these eddy currents penetrate the metal. This phenomenon is known as the skin effect.

At high frequencies, the eddy currents are forced to flow in a thin layer near the surface of the material. At lower frequencies, the currents can penetrate much deeper into the core of the metal.

Magnetic Stirring for Uniformity

A secondary benefit of this process is a natural stirring action. The forces created by the magnetic field and eddy currents cause the molten metal to circulate, ensuring a uniform temperature and consistent alloy composition.

Common Frequency Ranges and Their Applications

The "skin effect" is the reason induction systems are engineered for specific frequency bands. Each band is optimized for a different type of thermal processing.

Medium Frequency (MF) Furnaces: 200 Hz – 10 kHz

This is the workhorse range for most foundries and metal melting operations. The lower frequency allows the energy to penetrate deeply into the charge.

This deep penetration is essential for efficiently melting large batches of metal from a solid state. The strong magnetic field also creates a robust stirring action, which is ideal for mixing alloys.

High Frequency (HF) Furnaces: 60 kHz – 500 kHz

High-frequency systems are used when heating needs to be fast and localized. The shallow energy penetration is ideal for applications that don't involve melting large volumes.

Common uses include surface hardening of steel parts, brazing, soldering, and melting very small, specialized batches of material where speed is more important than deep heating.

Understanding the Trade-offs

Selecting a frequency is a balance between heating depth, speed, and equipment considerations. It is not a one-size-fits-all decision.

Penetration Depth vs. Heating Speed

This is the fundamental trade-off. A medium-frequency furnace heats the entire charge thoroughly but takes longer to bring a large mass to temperature. A high-frequency system heats the surface layer almost instantly but is inefficient for melting a large, solid block of metal.

Equipment Complexity

The power supply and control system are critical components. These systems must reliably generate the specified frequency and power, often using complex integrated circuits and silicon-controlled rectifiers (SCRs) to manage the high electrical loads. Higher frequency power supplies can be more complex and costly.

Coil Design

The induction coil itself must be engineered specifically for the furnace's operating frequency and the shape of the charge. An improperly designed coil will be highly inefficient and can lead to poor performance, regardless of the power supply's capability.

Making the Right Choice for Your Application

The optimal frequency is dictated entirely by your material and process goal.

- If your primary focus is melting large volumes of metal (e.g., a foundry): You require deep energy penetration for efficiency, making a medium frequency furnace the standard choice.

- If your primary focus is surface treatment (e.g., case hardening gears): You need precise, shallow heating, which makes a high frequency system the correct tool.

- If your primary focus is melting small, specialized batches quickly: A high frequency furnace can be more efficient and faster for small crucibles and precious metals.

Understanding the direct relationship between frequency and heating depth empowers you to select the most efficient technology for your specific industrial process.

Summary Table:

| Frequency Range | Primary Application | Key Characteristic |

|---|---|---|

| Medium Frequency (200 Hz – 10 kHz) | Large-scale metal melting | Deep energy penetration for efficient bulk heating |

| High Frequency (60 kHz – 500 kHz) | Surface hardening, brazing, small batch melting | Shallow, rapid surface heating |

Optimize your melting or heat treatment process with the right induction furnace.

At KINTEK, we specialize in providing high-performance lab equipment, including induction furnaces tailored to your specific application—whether you're melting large batches or performing precise surface treatments. Our experts will help you select the ideal frequency range to maximize efficiency, ensure uniform heating, and achieve consistent results.

Contact us today to discuss your laboratory needs and discover how our reliable solutions can enhance your productivity. Get in touch via our contact form for a personalized consultation!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting